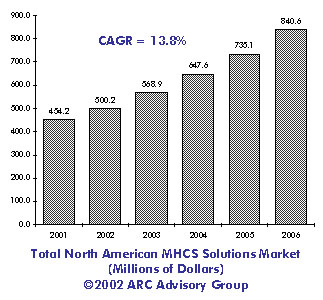

Material Handling Control Systems to Grow 13% Annually

Dedham, Massachusetts; April 5, 2002: Shipments of Material Handling Control Systems (MHCS) software and services reached nearly $494 million in 2001 in North America. This market is expected to grow at a Compounded Annual Growth Rate (CAGR) of over 13 percent over the next five years, according to a newly released ARC Advisory Group study, Material Handling Control Systems North American Outlook.

What Is a Material Handling Control System?

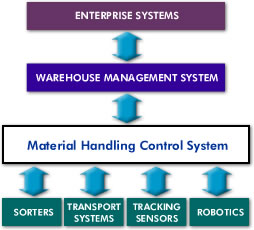

A primary purpose of an MHCS is to manage the routing of parcels, work-in-process, and inventory through a network of material handling equipment. “MHCS provides an interface between material handling systems and higher-level software application such as Warehouse Management Systems (WMS) in a warehouse and Collaborative Production Management (CPM) in the plants,” said Sal Spada (sspada@arcweb.com), ARC Director of Discrete Industry Research. This MHCS interface provides a means to access real-time information from plant equipment regarding material location and tracking. Quite simply, a comprehensive material handling solution today would not be complete without this MHCS software layer.

An MHCS solution provides a uniform interface to a broad range of material handling equipment that reduces operator training time, maintenance costs, and transportation time of individual goods. MHCS solutions are found in material handling systems for manufacturing plants, distribution centers, warehouses, and parcel handling centers. Managing the equipment in these facilities requires relatively sophisticated software that is capable of communicating directly to conveyors, sortation equipment, AGV, ASRS, and robots.

Supply Chain Visibility Fuels Growth

“Optimization of the sourcing, manufacturing, and delivery of goods is viewed as the next opportunity for businesses to improve profitability,” continued Spada. “A greater emphasis is on synchronization of the supply chain with customers and suppliers by improving the supply chain visibility. To be effective, extending the supply chain visibility depends upon greater reach of information on inventory in transit, work in process, and inventory in warehouses and distribution centers. As a result of this increased supply chain focus, MHCS solutions have taken on greater importance.”

MHCS solutions are capable of providing historical as well as real-time data to make process improvements in the equipment and staffing of warehouses and manufacturing solutions. Many companies are in the midst of adopting six-sigma initiatives which rely upon data analysis in order to justify and identify process improvements. Without accurate data on a service or manufacturing process to support decision making, organizations are unable to make informed decisions across departmental boundaries.

Automated Business Processes Drive Technology Adoption

Automated business processes are used to eliminate delays that result from human interaction. This technology leads to direct digital messaging between manufacturing units, external suppliers, and the high-level business systems. Mid-sized companies need to implement these solutions also, but are not blessed with large budgets. Therefore, solutions need to be incremental in nature. MHCS solutions eliminate manual business processes that lead to errors in orders or simply poor allocation of resources. Overall, the importance of MHCS solutions is to provide a greater degree of collaboration in the extended business enterprise.

ARC Advisory Group provides strategic planning and technology assessment services to leading manufacturing companies, utilities, and global logistics providers, as well as to software and solution suppliers worldwide. From Global 1000 companies to small start-up firms, ARC has the strategic knowledge needed to succeed in today’s technology driven economy. Further information can be obtained from Maryanne Flynn at ARC, Three Allied Drive, Dedham, MA 02026, 781-471-1160, Fax 781-471-1060.