Coronavirus

Technology Solutions

October 20, 2020

Koch Introduces High Dust Holding Capacity MERV

16 Filter

Automakers will be Upgrading Air Filter Systems

for the Long Haul

Baltimore Upgrading to MERV 13 Filters in City

Buildings

Argonne Developing Coatings and Nanofibers for

Masks

Powered Air Purifying Respirator for Everyday

Use

Biodegradable Mask Developed in UAE

iMune Nanofiber Filter and Electric Shield

Nanofiber Masks can be Sterilized Multiple Times

without Filter Performance Deterioration

______________________________________________________________________________

Koch Introduces

High Dust Holding Capacity MERV 16 Filter

Johnson Controls, a global leader for smart and

sustainable buildings, has just introduced the

KOCH™ DuraMAX line of air filters. With a range

of efficiency ratings from MERV 11 to MERV 16,

DuraMAX filters are a smart and safe upgrade

from bag filters and other box-style rigid

filters and effectively help lower the spread of

COVID-19 indoors.

The DuraMAX line of filters works alongside

other Johnson Controls HVAC products and

solutions to help make buildings more safe,

secure and sustainable.

“Primarily used for large commercial and

industrial applications, the DuraMAX line of

filters is a superior indoor air quality

solution to help a wide range of buildings

combat the spread of COVID-19 and other airborne

diseases,” said Mark Mattingly, vice president

and general manager, Air Filtration Products,

Johnson Controls. “These medium and

high-efficiency filters include the DuraMAX 4V

and 4VS-16 with an industry-leading MERV 16

rating and low resistance to airflows, allowing

customers to save money on energy costs while

experiencing the highest levels of filtration.”

Tested in accordance with ASHRAE Test Standard

52.2-2017, DuraMAX is an ideal choice in

filtration systems with high velocities or

variable air volumes. The high-capacity

mini-pleat design allows a nominal 24x24x12

filter to incorporate 194 square feet of filter

space, which creates an extremely high

dust-holding capacity to significantly prolong

the service life of the filter.

The DuraMAX 4v is designed to replace almost any

competitive high-efficiency air filter in

today’s market. The lightweight, all-plastic

frame installs into side-access housings or

front-load holding frames and is an ideal choice

to replace bag filters and other box-style rigid

filters. The durable, all-plastic frame makes

the DuraMAX 4v the filter of choice in

filtration systems with high velocities,

variable air volumes and high moisture, or in

areas where the user desires to incinerate the

filters after use.

Automakers will be Upgrading Air Filter Systems

for the Long Haul

COVID may not be a serous threat a few years

from now but for the automobile industry the

upgrade of filtration systems to remove diesel

soot as well as COVID will be permanent.

Chinese automaker Geely Auto, whose parent

company owns high-end brands Volvo and

Lotus, announced in February that in response to

the coronavirus, its forthcoming Icon electric

SUV would feature an N95-certified air

purification system that could “isolate and

eliminate harmful elements in the cabin air”

including viruses. The same month, Geely said it

would invest about $54 million to build

“healthier cars” with “comprehensive virus

protection.”

Volvo and Lincoln are rolling out advanced air

filtration systems for 2021 models. They use

sensors to identify tiny particles and enhanced

filters to clean the air that enters a car’s

cabin, a version of technologies that Tesla has

offered since 2015. While those systems are not

being touted by the manufacturers as protection

measures against COVID-19, that doesn’t mean

anxious — and flush — car buyers won’t pay for

any add-on that might make their trip to the

country club for socially distanced brunch at

least feel a bit safer.

“As a product, of course it has viability,” said

Mike Ramsey, automotive analyst at Gartner Inc.

“Luxury car makers are trying to cook up new

ways to

differentiate the product from vehicles that are

largely the same but much cheaper.”

The coronavirus is ordinarily spread through

respiratory droplets passed among people in

close contact, more often than not indoors,

according to the Centers for Disease Control and

Prevention. Contracting the virus from driving a

car through contaminated air seems an edge case,

to say the least.

A

far more likely means of catching the virus

inside a car would come from traveling with an

infected passenger.

No

automobile cabin air filter can prevent one

passenger from transmitting a virus to another —

a fact endlessly repeated in the media maelstrom

that followed President Trump’s controversial

motorcade drive-by Oct. 4 while he was fighting

COVID-19. Doctors say the best bet is to travel

only with people you’re reasonably sure do not

have the virus.

Baltimore Upgrading to MERV 13 Filters in City

Buildings

The Department of General Services has been

replacing air filters in the Mitchell and

Cummings courthouses, upgrading the type

normally used to MERV 13-rated filters,

following recommendations by the Centers for

Disease Control and Prevention.

“Those are the most efficient, high-efficient

that our systems can accommodate. They have a

better filtration rate,” General Services

Division Chief Terrel Chesson said.

But making the changes can create new

challenges.

“PPE costs. Air filters cost -- that was not

part of our budget,” Baltimore City Schools CEO

Sonja Santelises said.

Recently, Santelises described what it takes to

ensure school buildings are healthy.

“The reality is these precautions cost. They are

not cost-free and the older the buildings are,

older facilities are, the more it takes. It's

not just the change of an air filter, it's

additional precautions as well,” she said.

As schools handle their issues, DGS tells 11

News it is responsible for 89 city properties,

managing the airflow systems in 77 of them,

including City Hall. The department began

installing MERV 13-filters in May.

“We've had a stance of continuing to work on the

facilities, find ways to make the facilities

safer,” Chesson said.

General Services says it's replacing air filters

in city buildings every three months. So far,

it's spending $164,000 changing filters now and

again at the end of the year.

Argonne Developing Coatings and Nanofibers for

Masks

They’re known for big science – super computers

and sequencing proteins. But at the same time,

scientists at Argonne National Laboratory simply

want to make better masks.

They’ve been working on ideas since the early

days of the pandemic. And now they’re ready to

roll them out.

Research is being conducted on the 1700-acre

campus in southwest suburban Lemont.

Jeff Elam PhD. and his colleague Anil Mane PhD.

work with chemical coatings and materials.

“When the pandemic hit a lot of us were working

from home but there was sort of a call to arms,”

Elam said.

When COVID-19 hit, they had an idea that

inspired them to quickly return to their lab.

“The masks you and I are wearing now are

intended to prevent droplets from coming out of

our mouth and infecting other people,” Elam

said. “It will catch those droplets. But they

will still remain infective. If you can kill the

microbes, you could make them even more

effective to reduce the spread of the virus.”

They started tinkering with an N95 mask you’d

find at a hardware store.

“Once you take out the mask material there are

different layers,” Mane said.

N95s contain an electrostatic layer of material

that catches tiny viral particles. It’s what

makes them so effective.

But the Argonne team believed a chemical coating

would make the workhorse even more powerful by

killing the viral particles caught in the

fibers.

They experimented on small pieces of N95

material and ran samples through a tube where

vapor pulses applied a specially formulated

antimicrobial coating.

“What we want to do is put a coating, not just

on the surface of that fabric, but inside of

every one of the little fibers that are used to

make that mask so it will be effective at

killing the virus,” Elam said.

Once they found the right formula, they tested

their “catch and kill” material layer against

bacteria and viruses, including a SARS-CoV2

surrogate.

“We tested this mask with antivirus

antibacterial samples, and it’s worked greatly,”

Mane said.

“The coatings are general. Although we developed

them for N95 masks, we think we could just as

easily put them on gloves, protective eyewear

and even on filters for buildings,” Elam said.

Tucked away in a corner of the massive campus,

more mask research is underway.

Materials scientist Yuepeng Zhang PhD. and her

team have been spinning nano-fibers since April

and “making a new N95 filter material that could

be an alternative solution to the commercial

N95,” she said.

It’s made on what looks like a high-tech loom.

Tiny jets spin fibers 1500 times thinner than a

human hair. Their special polymer solution

contains anti-viral ingredients that get

embedded in the fibers.

“We put the anti-viral compound or nano

particles into the electro-spinning solution, so

either way we actually embed the anti-viral

ingredients inside our nano fibers,” Zhang said.

Both the mask shell and thin filter are reusable

and washable using common soapy water, alcohol

or bleach solutions. And the fibers contain an

extra virus-fighting property.

“When people wear masks for a long time, it’s

very uncomfortable and you have a hard time to

breathe,” Zhang said. “You have a better face

fit and more comfort when you wear them.”

The design isn’t just for healthcare workers.

The thin layer can be applied to any piece of

cloth.

The entire team has been working tirelessly

hoping they can make a difference on the

frontline of the pandemic by bringing their

ideas to the assembly line.

Much of the work at Argonne is supported by the

Department of Energy. And now the scientists

there hope to hand off their ideas to

large-scale manufacturers who can bring their

masks to the masses.

Powered Air Purifying Respirator for Everyday

Use

ValhallaMED, a manufacturer of MedTech devices

designed to fight Covid-19, launched the

crowdfunding campaign for the NE-1 Helmet™ on Indiegogo.

Created for anyone, anywhere, the personal

protective gear solves mask-related problems in

the "New Economy" to provide visibility, clarity

and comfort ideal for healthcare professionals,

essential workers, the hearing impaired and

anyone with preexisting health conditions.

The Bluetooth audio and external speakers are

ideal for "close-talkers" and "low-talkers"

alike.

While conventional fabric masks present

breathing challenges, the NE-1 is the

first-of-its-kind powered

air purifying respirator for everyday use.

The smart PPE uses nanofiber filters to remove

more than 95 percent of harmful bacteria and

virus particles in the air while providing

constant, cooling air flow. Each helmet also

comes equipped with an anti-fog, anti-glare face

shield for a 360-field of view and Bluetooth

audio to hear and be heard.

"Face masks have become an everyday essential

and we set out to create a more ideal solution

that would eliminate the need for disposable

masks while offering the height of protection,"

said Chris Ehlinger, founder of ValhallaMED.

"There are still many reasons to meet in person.

Lack of quality air shouldn't inhibit us."

The NE-1 responsibly reopens the economy with an

airtight neoprene seal, allowing effective

coverage against exposure for high-contact

workers. The helmet's unique, ergonomic shape

accommodates a wide range of face sizes to meet

the global demand of high-quality breathing

protection.

The NE-1 Helmet is offered for both men and

women at a retail value of $299. Consumers can

take advantage of the early-bird special and

pre-order on Indiegogo starting at $139.

ValhallaMED is also offering a special reward

level, "Give One, Get One," that provides

helmets to frontline healthcare workers.

"At ValhallaMED, we're on a mission to take back

tomorrow and the most important feature of the

NE-1 helmet is that we are delivering it at

cost. Every extra dollar will go toward getting

the helmet to someone who needs it most,"

finished Ehlinger.

Biodegradable Mask Developed in UAE

A 100 per cent biodegradable mask

has been developed in the UAE, it was announced

on Monday. A team of researchers from the

Khalifa University developed the first working

prototypes of the environment-friendly NavaMASK.

It is a fully biodegradable and biocompatible

anti-viral adaptive face mask. It is made of

nano-fibers, giving it strong anti-microbial

properties.

“We recognized the need for an

environment-friendly alternative to the

currently available face masks in the market,

(while) ... maintaining the highest safety and

breathability standards," said Dr Shadi W. Hasan,

associate professor chemical engineering at

Khalifa University. "The first prototypes of the

NavaMASK is fully biodegradable. It's made of

filtration materials that were carefully

selected to provide effective protection, avoid

skin irritation and, most importantly, be safe

on the environment."

The face mask has perpendicular arranged

nanofibers with a diameter ranging between 100

and 600 nanometers which will allow air to pass

through, but reject particles, bacteria and

viruses. The mask's strong anti-microbial

properties will ensure more than 99 per cent

removal of bacteria.

"It is expected that NavaMask will compete and

outperform many of the existing face masks in

the market," said Hasan. "We are working

together with our collaborators and partners

towards developing a new second generation

design of NavaMASK aimed at maintaining high

removal efficiency and high comfortability and

easier breathability with fewer layers.

iMune Nanofiber Filter and Electric Shield

iMune has launched a smart nanofiber electric

shield,

iMune says

its masks are cost effective in comparison with

alternatives including surgical masks,

disposable masks, N95 masks, and reusable

respirators, and they provide total protection

with an airtight seal, PMO.3 microns particle

filtration efficacy, air filtration and

purification, and comfort. iMune masks protect

against viruses as small as 0.01 microns,

particulate matter down to PM2.5, formaldehyde,

harmful gases, and allergens.

What truly sets iMune masks apart are a smart

fan and motor that efficiently purify air that's

being breathed in and out.

The filters, which are class 5 super composite

filters, can last for seven days with the fan on

high speed and feature high density fiber

filtration, crystalline activated carbon, and

are both HEPA H11 medical grade and a PP cotton

sterilization filter. Due to the sterilizing

components in the filter, it is capable of

neutralizing and killing anything that tries to

get through it.

In addition, silent yet strong engine features

three speed settings and can last up to eight

hours per charge. A USB charging cord is

included with the mask. Also included in the box

are three filter covers, a headband, an ear

band, an anti-dust bag, and a user manual.

For people who are tired of their skin being

irritated by masks, iMune has used baby food

grade soft silicone in the design to reduce and

even eliminate irritation for total comfort.

Nanofiber Masks can be Sterilized Multiple Times

without Filter Performance Deterioration

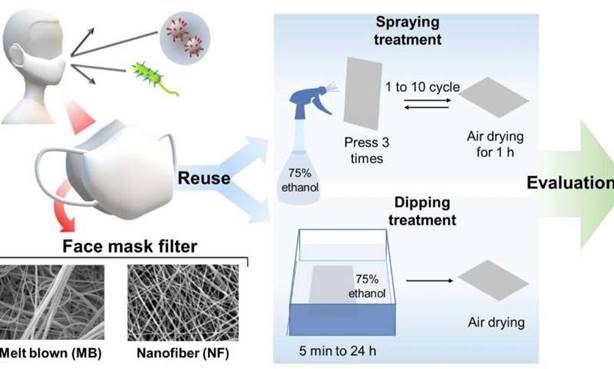

Schematic diagram on spraying and dipping

treatments of face mask filters.

Credit: ©2020 American Chemical Society

With the global spread of coronavirus

infections, personal protective equipment,

especially face masks, are receiving much

attention. Masks are essential items for the

primary protection of the respiratory tract from

viruses and bacteria that are transmitted

through the air as droplets.

N95 masks are currently difficult to obtain, so

there is an urgent need for a safe method of

prolonging their usability through disinfection

and reuse with minimal loss of performance and

integrity. Particulate filtration and air

permeability are key factors in determining

performance while cleaning and disinfecting N95

certified masks. This is crucial in preventing

infections. Shinshu University has a track

record of conducting research on production

methods and applications of "nanofiber non-woven

fabric" since before the coronavirus outbreak.

Amidst the current social backdrop, a research

team led by Professor Ick Soo Kim of Shinshu

University's Institute for Fiber Engineering

(IFES) with Ph.D. students Sana Ullah and Azeem

Ullah and Professor Cha Hyung Joon of POSTECH

(specially invited professor of IFES) with Ph.D.

students Jaeyun Lee and Yeonsu Jeong, looked

into the effectiveness of sterilizing N95 masks.

They looked at commercially available melt-blown

nonwoven fabric N95 masks and nonwoven nanofiber

masks with N95 filters. They examined the

filtration efficiency, comfort of the wearer,

and filter shape change after washing and

disinfecting. The methods of disinfection test

involved directly spraying 75% ethanol on the

mask filter and air drying and soaking the mask

filter in 75% ethanol solution for 5 minutes to

24 hours and leaving it to air dry naturally.

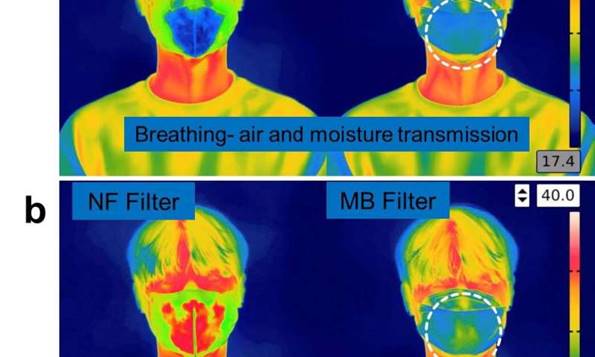

Evaluation of breathing comfort by infrared

thermal camera.

Credit: © 2020 American Chemical Society

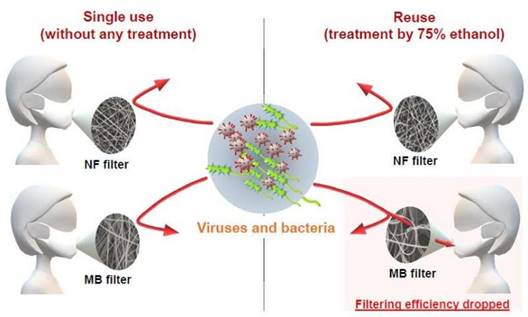

Filtration efficiency of both of the filters

(melt-blown filter and the nanofiber filter) was

95% or more before use, which indicates that the

respiratory organs of the wearer can be

effectively protected. The tests also clarified

that the inside of the filter can be effectively

sterilized by spraying ethanol three times or

more or immersing it in an ethanol solution for

more than five minutes.

However, when the

mask was reused after the ethanol disinfection,

the filtration efficiency of the melt-blown

filter decreased to 64%. On the other hand, the

nanofiber filter did not deteriorate in filter

performance even after ten or more uses.

Melt-blown filters work on the principle of

electrostatic charge for the removal of

particulate matter, as in the result of ethanol

spraying or dipping the electrostatic charge on

the surface of melt-blown filter was lost, so

efficiency of melt-blown filter was

significantly decreased. On the other hand,

filtration mechanism of nanofiber filter is

independent of static charge and fully dependent

on pore diameter, pore distribution, and

morphology of nanofibers. As in the result of

disinfection, morphology of nanofibers was not

affected, thus it also maintained its filtration

as optimum as it was before use.

In addition, the nanofiber filter has higher

heat emission and carbon dioxide emission

performance than the melt-blown filter and

exhibits excellent breathability. Similarly, it

was confirmed that the nanofiber filter had

lower cytotoxicity than the melt-blown filter

when a safety experiment using human skin and

vascular cells was performed.

Comparison of mask filter performance after

ethanol disinfection: The nanofiber filter has

air permeability even after being washed. The

melt-blown filter has its mesh structure changed

by ethanol sterilization and its performance is

deteriorated.

Credit: © 2020 American Chemical Society

As stated above, both mask filters have similar

filtering performance at the time of first use,

but after disinfecting and reusing, the

nanofiber filter does not exhibit performance

deterioration. In other words, nanofiber filters

can be easily sterilized with ethanol at home

and reused multiple times.

"This research is an experimental verification

of the biological safety of nanofiber masks and

the maintenance of filtration efficiency after

washing, which has recently become a problem,"

Professor Cha Hyung Joon states, who co-presided

the research. Professor Ick Soo Kim hopes that nanofiber masks

will serve as a means of prevention in the

second and third wave of coronavirus infections.