Coronavirus Technology Solutions

June 24, 2020

Treat Each Person as a Cleanroom

Product

Radiant Fibertech PVT Supplier

of Face Mask Fabric

Suominen Introduces New Material

for EN Type II Facemasks

AKAS Layered Fabrics Outperform

N95 Meltblown in Filtration

Efficiency

Jacob Holm Teams with Under

Armour on Face Masks

H&V Continues to Expand Capacity

to Mitigate

COVID

Nanofiber Masks Compare

Favorably in Both Efficiency and

Comfort

Investors Discuss New Startups

in the COVID Battle

____________________________________________________________________________

Treat Each Person as a Cleanroom

Product

To protect pharmaceutical

products from airborne

contamination we do not consult

with doctors or epidemiologists,

we instead rely on cleanroom

specialists.

We do not rely on distancing the

product from the source of

contamination instead we protect

the product by assuring that the

air with which it comes in

contact is as free of

contaminants as possible.

Billions of dollars have

been spent by the cleanroom

industry to achieve this goal.

It is their expertise

which needs to be absorbed by

government decision makers.

COVID is not transmitted by

fleas, mosquitoes or

contaminated food. Transmission

through touching surfaces is now

being downgraded as a source.

The consensus main source is

aerosols.

There is disagreement

about what percentage is from

small aerosols which travel long

distance as

opposed to those that

travel less than six feet.

But in either case the

purification of the air being

inhaled is the solution.

We are relying primarily on the

advice of physicians and

epidemiologists in making what

has proven to be some disastrous

decisions (e.g. not wearing

masks and not worrying about

HVAC systems).

These would be the first

areas of focus for a

cleanroom designer. The new

evidence of the way COVID is

transmitted should lead us to

cleanroom experts and treat

people the way we would a

valuable pharmaceutical product.

Radiant Fibertech PVT Supplier

of Face Mask Fabric

Radiant Fibertech Pvt. Ltd.

started the production of

nonwoven fabric in 2012 with the

brand name REDIFIL. The Indian

manufacturing plant is located

on Rajkot – Gondal National

Highway No. 8-B, at Bhunava. The

prime aim for selecting the

plant location is the proximity

of the plant to transportation

facility, continuous power

supply and availability of

skilled & semiskilled labors.

With the main objective of

protecting the environment from

degradation, they are committed

to supply quality nonwoven

fabric made from 100%

Polypropylene which is durable,

attractive, cost effective and

eco-friendly. It is producing

nonwoven fabric from 10 GSM to

200 GSM with maximum width of

1600 mm with more than 25

attractive colors. The installed

capacity of the

plant is 1800 mt./annum

which is used for

·

Surgical Gowns & Aprons

·

Face masks,

·

Gloves & caps

·

Top sheets of Baby Diapers

·

Fastener tapes for Baby

Diaper[BM1]

Suominen Introduces New Material

for EN Type II Facemasks

Suominen has developed a

nonwoven material for the

manufacture of facemask

applications. The new nonwoven

has passed European Standard EN

14683:2019 Type II requirements

in terms of filtration

efficiency and pressure drop.

“Our FIBRELLA Shield nonwoven

has excellent filtration

efficiency and pressure drop

values meaning that the material

provides protection while being

comfortable and easy to breathe

through. Measured with an

applied method by VTT results

indicate that FIBRELLA Shield

nonwoven’s filtration efficiency

is higher than 99% reaching type

II requirements but of course

the material can also be used

for lighter model Type I masks

or uncertified masks,” said

Category Manager, Johanna Sirén.

The standard EN14683:2019 for

medical masks is for end

products and the converter has

to repeat the tests to confirm

the standard compliancy for the

end product. The end product

needs to comply also with the

regional regulations, if any.

Developed in cooperation with

VTT, this new material is the

latest addition to the FIBRELLA

family. FIBRELLA Shield is

already in production at

Suominen’s Nakkila plant in

Finland. Currently the plant is

capable of producing material

for approximately 15 million

masks per month.

AKAS Layered Fabrics Outperform

N95 Meltblown in Filtration

Efficiency

A new study by Northeastern

University found that a facemask

constructed using fabrics

manufactured by AKAS Textiles, a

Pennsylvania-based textile

manufacturer, outperformed an

N95 respirator in an aqueous

media under positive pressure of

20 Kilo Pascal, simulating a

sneeze/cough. The study tested

more than 70 different common

fabric combinations and masks,

including the N95 respirator,

for their ability to block the

transmission of virus-like

nanoparticles. The mask with the

best filtration was made of

layers of ProCool Performance

Fabrics combined with Zorb 3D

Stay Dry Dimple fabric. The

combination of these fabrics

tested 72% more effective than

the N95 respirator.

The study was published in ACS

Nano, a monthly,

peer-reviewed scientific journal

published by the American

Chemical Society. The authors

wrote, “Layered systems of

commonly available fabric

materials can be used by the

public and healthcare providers

in face masks to reduce the risk

of inhaling viruses with

protection that is about

equivalent to or better than the

filtration and adsorption

offered by 5-layer N95

respirators. The masks were

evaluated with steady-state,

forced convection air flux with

pulsed aerosols that simulate

forceful respiration”.

Jacob Holm Teams with Under

Armour on Face Masks

Jacob Holm, the manufacturer of

Sontara fabrics and other

nonwovens for medical and wipes

applications, is ramping up

material for PPE. The company

will implement a company-wide

investment program that would

lead to a 500 million square

meter capacity expansion

annually. The program, called

Project Boost, began last month

and will be completed by the

third quarter of 2022.

“Project Boost is our response

to the needs of our partners

across the globe for increasing

capacity, providing more

sustainable substrate choices

and continuing to hold our

position as an innovation leader

in nonwovens,” says CEO Martin

Mikkelsen.

Last month, the company reported

that it had seen a 65% increase

in its Sotnara medical fabric

during the Coronavirus pandemic,

leading two of its five sites to

report record production levels

in April.

“This situation is

unprecedented,” Mikkelsen says.

“However, for Jacob Holm as a

company, the only way forward is

to lean in to what we know and

use the full force of our

experience to help contain the

spread of COVID-19 and make a

positive impact on the wellbeing

of our communities.” Among Jacob

Holm’s efforts in the fight

against Covid-19 was a

partnership with sport

performance brand Under Armour

to make face masks and isolation

gowns.

H&V Continues to Expand Capacity

to Mitigate

COVID

Hollingsworth & Vose, has

shifted its focus beyond its

traditional markets like

medical, automotive and

filtration to create a material

for non-surgical gowns on an

accelerated timeline. “H&V had

already been manufacturing

critical materials used in the

fight against Covid-19 including

filtration media for N95

respirators, ventilator

filtration media and the

materials used in surgical hoods

so it made sense for us to see

how else we might be able to

meet the needs of healthcare

workers on the front lines,”

says Jeff Crane, segment leader,

H&V.

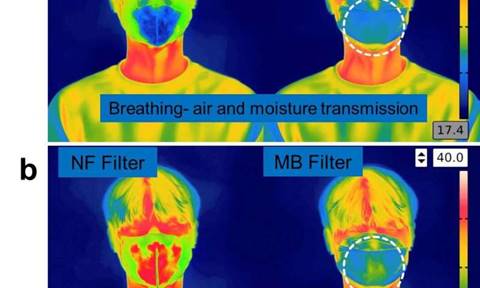

Nanofiber Masks Compare

Favorably in Both Efficiency and

Comfort

A research team led by Professor

Ick Soo Kim of Shinshu

University's Institute for Fiber

Engineering (IFES) looked into

the effectiveness of sterilizing

N95 masks. They looked at

commercially available

melt-blown nonwoven fabric N95

masks and nonwoven nanofiber

masks with N95 filters. They

examined the filtration

efficiency, comfort of the

wearer, and filter shape change

after washing and disinfecting.

The methods of disinfection test

involved directly spraying 75%

ethanol on the mask filter and

air drying and soaking the mask

filter in 75% ethanol solution

for 5 minutes to 24 hours and

leaving it to air dry naturally.

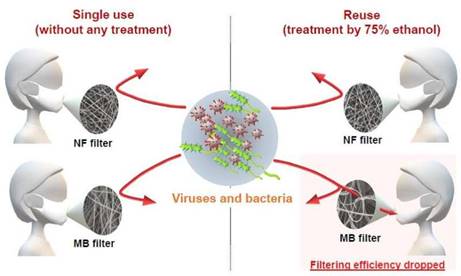

Filtration efficiency of both of

the filters (melt-blown filter

and the nanofiber filter) was

95% or more before use, which

indicates that the respiratory

organs of the wearer can be

effectively protected. The tests

also clarified that the inside

of the filter can be effectively

sterilized by spraying ethanol

three times or more or immersing

it in an ethanol solution for

more than five minutes. However,

when the mask was reused after

the ethanol disinfection, the

filtration efficiency of the

melt-blown filter decreased to

64%. On the other hand, the

nanofiber filter did not

deteriorate in filter

performance even after ten or

more uses.

Melt-blown filters work on the

principle of electrostatic

charge for the removal of

particulate matter, as in the

result of ethanol spraying or

dipping the electrostatic charge

on the surface of melt-blown

filter was lost, so efficiency

of melt-blown filter was

significantly decreased. On the

other hand, filtration mechanism

of nanofiber filter is

independent of static charge and

fully dependent on pore

diameter, pore distribution, and

morphology of nanofibers. As in

the result of disinfection,

morphology of nanofibers was not

affected, thus it also

maintained its filtration as

optimum as it was before use.

In addition, the nanofiber

filter has higher heat emission

and carbon dioxide emission

performance than the melt-blown

filter and exhibits excellent

breathability. Similarly, it was

confirmed that the nanofiber

filter had lower cytotoxicity

than the melt-blown filter when

a safety experiment using human

skin and vascular cells was

performed.

Comparison of mask filter

performance after ethanol

disinfection: The nanofiber

filter has air permeability even

after being washed. The

melt-blown filter has its mesh

structure changed by ethanol

sterilization and its

performance is deteriorated.

As stated above, both mask

filters have similar filtering

performance at the time of first

use, but after disinfecting and

reusing, the nanofiber filter

does not exhibit performance

deterioration. In other words,

nanofiber filters can be easily

sterilized with ethanol at home

and reused multiple times.

"This research is an

experimental verification of the

biological safety of nanofiber

masks and the maintenance of

filtration efficiency after

washing, which has recently

become a problem," Professor Cha

Hyung Joon states, who

co-presided the research.

Professor Ick Soo Kim hopes

that nanofiber masks will serve

as a means of prevention in the

second and third wave of

coronavirus infections.

Investors Discuss New Startups

in the COVID Battle

This is a summary of a live

panel ran by SOSV to

introduce and discuss solutions

funded by some of the most

active investors in the field.

Each of the three funds (Fifty

Years, Khosla

Ventures, SOSV)

had published an impressive list

of their relevant portfolio

startups. IndieBio even made a call

to fund Covid-fighting startups as

part of its newly launched NYC

program.

Protecting our face

-

Many masks don’t

effectively

protect against

infection as the

virus is too

small (about

120nm). Verdex (a

SOSV portfolio

company) has

developed a

nanofiber

material that

filters out

particles above

100nm —

effectively

blocking the

virus — and is

also more

breathable.

-

HabitAware,

a HAX portfolio

company, had

created a

machine-learning-powered

bracelet to

prevent

body-focused

repetitive

behaviors (e.g.

nail biting) by

recognizing and

alerting of

specific

gestures. The

pandemic

provided a new

direct

application of

their technology.

Disinfecting everything

The ‘new normal’ is making

frequent and thorough

disinfection of our living and

working environment necessary,

to protect us and helps us get

back to work.

-

HAX has invested

in various

solutions for

this, from floor

cleaning (Avidbots)

to toilet

cleaning (Somatic).

-

The dry cleaning

robot startup

Presso announced

its solution initially

intended for

business travels

was now in

high-demand with

movie and TV

studios who are

resuming

operations.

-

Youibot,

an autonomous

logistics

startup, managed

to repurpose

their technology

to provide

disinfection

with UV-C

lights, and

temperature

detection.

Testing with devices

On the testing front, several

countries have introduced

testing stations that look like

phone booths. Some are also

using helmets with IR sensors to

detect potential infections.

Some wearable device companies

like Oura and Strados

Labs are

applying their technology to

pre-symptom detection or

monitoring.

Treatment

Treating the virus is

complicated, as it might also

involve treating the immune

response, and support the

recovery of patients.

·

Various large and small

companies are working on vaccine

candidates,

·

Some companies are trying to

develop new drugs, or repurpose

existing ones for a faster

time-to-market

The lack of equipment —

particularly respirators — is

being addressed partly by

repurposing other devices. Among

them are snorkeling masks and

BIPAP/CPAP machines. Decathlon

donated their stock of

snorkeling mask to hospitals.

Finally, alongside this pandemic

comes tremendous emotional harm

due to stress, economic

uncertainty and unemployment.

Some companies such as Feel are

working on low-cost solutions to

help people improve their mental

health.

Seth Bannon, Founding Partner at

Fifty Years

-

The Covid-19

threat is

reminiscent

of WWII, with

potential deaths

in the tens of

millions.

-

WWII gave us

many tech

innovations such

as: mass

production of

antibiotics,

blood plasma as

a therapeutic

solution, skin

grafts, flu

vaccine, radar,

microwave ovens,

pressurized

plane cabins,

nuclear power

and the first

programmable

digital

computer. It

laid the

foundation of

technical

progress for

many years to

come. A similar

rally today

could build

solutions for

the future.

-

Everyone who can

help should

help, and 17

of our portfolio

companies did.

-

HelixNano (from

the George

Church lab at

Harvard).

Working on

a vaccine to

counteract

SARS-Cov-2

evolutions and

antigenic drift.

-

BillionToOne found

a way to run

a test on Sanger

sequencers at

low cost and

high volume.

-

Opentrons (a

co-investment

with Khosla and

SOSV) built a

low-cost lab

robot to

automate liquid

handling,

already deployed

in multiple labs

around the world

to test covid.

An Opentrons robot in Italy

(source: 24ORE)

-

Voodoo

Manufacturing directed

their cloud farm

of 3D printers

to focus on combating

Covid-19 by

producing PPE

and more at

cost.

-

Solugen,

that makes

hydrogen

peroxide,

realized they

had the capacity

to

make hand sanitizer and

now do so

pro-bono.

Alex Morgan, Partner at Khosla

Ventures

-

Khosla has over

$1B under

management,

including a main

and seed fund.

-

The goal is to

‘reinvent social

infrastructure

with

technology’,

looking for

investments

combining

financial

returns with

societal impact

(e.g. Impossible

Foods, Color,

etc.). We

also have a list

of companies

responding to

Covid-19.

-

Genalyte has

a

FDA-approved testing solution that

takes 15min.

Current capacity

is about~250k

patients /

month.

-

Luminostics designed

an optical test that

can be run with

a small device

attached to a

phone.

-

Pardes Bio is a

recent

investment

working on

a therapeutic using

a protease

inhibitor.

-

Prellis

Biologics (IndieBio/SOSV

co-investment)

is a tissue

engineering

company that can

3d print lymph

nodes ex vivo to

produce therapeutic antibodies (here

are a recent video

interview and media

coverage).

-

Some other

investments also

focus on

the distribution

of care, and

particularly mental

health, such as Ginger (remote

service for

mental health)

and Flow

Neuroscience (a

SOSV/HAX

co-investment

offering a

drug-free

treatment for

depression using

an at-home brain

stimulation

device, already

on sale in

EU/UK).

Jun Axup, Chief Science Officer

& Partner at IndieBio

-

IndieBio is

the life

sciences

accelerator

program of SOSV,

based in SF and

NYC and

investing

globally. It

invested in 136

companies

including

Memphis Meats,

Clara Food and

Perfect Day in

the cellAg

space.

-

CASPR Biotech uses

·

CRISPR for low-cost testing

(covered by NYT).

·

Renegade.Bio was

founded as a lab to test at high

speed and large volume.

·

ANA

Therapeutics is

repurposing an anti-worm

treatment toward Zika, SARS and

now Covid.

·

Halomine found

a way to keep surfaces free of

viruses by stabilizing chlorine,

making the protective film last

up to 30 days instead mere

hours.