Coronavirus Technology Solutions

May 13, 2020

Comfort Ventilation with

Anti-Microbial Coatings can be

Repurposed to Fight COVID

Marley Engineered Products

Provides Anti-Microbial Coated

Ventilation Products

Don & Low will Add New Meltblown

Line for Face Masks in UK

Freudenberg Face Masks Made

Available This Week

Drylock will Make 100,000 Masks

per day in Spain

Kolmi-Hopen one of Four Major

Manufacturers of N95 Masks in

France

Ahlstrom -Munksio Media Being

Used by French Mask Makers

Battelle H2O2 Decontamination

System Being Deployed at Sixty

Locations

Lehigh University and St Luke’s

Team to Provide UV Mask

Decontamination

UV Finding Decontamination Uses

on Subways and Buses

____________________________________________________________________________

Comfort Ventilation with

Anti-Microbial Coatings can be

Repurposed to Fight COVID

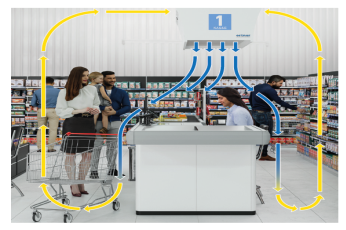

Comfort heating and ventilation

products with anti-microbial

coatings can be repurposed to

direct HEPA filtered air through

the breathing zones of occupants

or to direct fresh outside air

into the breathing zone. Small

COVID aerosols act like

cigarette smoke. The ideal

system allows pure air to flow

downward and then potentially

contaminated air to be removed.

This example in a dentists

office was supplied by Blue Sky

Global.

The

proportion of recirculating and

purifying air with HEPA filters

versus introduction of more

outside air is dependent on

costs such as heating the

outside air. The use of

anti-microbial coatings in

ductwork and components which

can come into direct contact

with people is also important.

Marley Engineered Products

Provides Anti-Microbial Coated

Ventilation Products

Marley Engineered Products, LLC

draws upon a long history of

providing reliable comfort

heating and ventilation

solutions. It has manufacturing

operations in Bennettsville,

South Carolina along with

regional sales representatives

located throughout the United

Sates.

The company offers

anti-microbial coating on

ceiling panels, cabinet unit

heaters, convector heaters and

wall heaters.

All healthcare facilities

require comfort heating systems.

Systems that can be enhanced

with an antimicrobial coating

include those in:

·

Hospitals and Doctors’ Offices:

Radiant panels with

antimicrobial coating are ideal

for keeping people warm without

blowing heat and spreading

germs.

·

Waiting Rooms: Cabinet unit

heaters with antimicrobial

coating in waiting rooms supply

additional heat for comfort

while minimizing germs.

·

Geriatric Centers and

Assisted-Living Facilities: Wall

heaters or radiant heating

panels with antimicrobial

coating are useful for providing

gentle comfort while preventing

the spread of harmful bacteria.

There are a host of commercial

and institutional spaces that

can benefit from electric

heating products that feature

antimicrobial finishes:

·

Restaurants: Steel or aluminum

convectors can be placed along

windows to keep the cold out

while helping maintain high

cleanliness levels.

·

Daycare Centers: Radiant panels

installed on ceilings keep

children warm and, because the

panels are out of reach, keep

children safe.

·

High Schools and Universities: A

variety of heaters can be

installed in spaces that include

classrooms, hallways,

dormitories, restrooms, locker

rooms and more.

Airports, office buildings and

dozens of other applications

also could benefit from comfort

heating solutions with

antimicrobial coatings. Many

facilities today seek customized

solutions beyond standard

heating for improved quality of

life.

Marley also makes air curtains.

Air curtains are used for a

variety of applications from

thermal barriers at drive-thru

windows to pest prevention. They

enable traffic to flow

unobstructed through openings

while maintaining separate

environments, resulting in

energy savings. Spaces like

supermarkets, schools,

hospitals, restaurants,

cafeterias, malls, and

processing plants are ideal for

electric air curtains.

The main purpose of air curtains

has been comfort from a

temperature perspective. But

these air curtains can also

insure that air moves in the

downward direction away from the

breathing zone.

This is an example

provided by Ortner.

In summary comfort heating and

ventilation with anti-microbial

coatings can be repurposed for

cost effective coronavirus

mitigation.

Don & Low will Add New Meltblown

Line for Face Masks in UK

Don & Low will add a new

meltblown line in Forfars,

Scotland with the help of the

Scottish

Government. The government

reportedly supplied £3.6 million

of the £4.5 million cost of the

supply and installation of the

new line, which will produce

meltblown material filter fabric

for use in FFP3 masks, the

highest designation of

respirator.

It will make Don & Low one of a

handful of companies in Europe

capable of supplying the filter

material used to make the

respirator masks.

Scottish Government Minister for

Trade, Investment and

Innovation, Ivan McKee, says:

“Covid-19 isn’t going away any

time soon, so while we have

enough masks to protect our

frontline health and social care

workers now, we are also taking

a long-term view to build PPE

manufacturing capability in

Scotland to meet future need.

During these challenging times

it’s encouraging to see so many

Scottish businesses quickly

diversify their product lines

and invest in new equipment to

help us deliver what is needed,

when it’s needed.”

Don & Low director, Colin

Johnson says: “We are pleased to

be supported in making this new

investment that will allow us to

use our existing expertise to

address the shortages of these

key materials during the

COVID-19 pandemic and beyond.”

In late March, Don & Low

announced part of its business

would close to allow the company

to direct efforts towards the

production of face masks for NHS

workers. It said the company’s

woven textile manufacturing

facility would shut, with

available staff transferred to

nonwovens production.

Freudenberg Face Masks Made

Available This Week

Freudenberg

has started producing mouth-nose

masks for end-consumers. The

masks under the brand name “Collectex”

are now available in the Vileda

online shop and from retail

partners of the Freudenberg Home

and Cleaning Solutions Business

Group – initially only in

Germany.

Three Freudenberg Business

Groups – Freudenberg

Filtration Technologies, Freudenberg

Home and Cleaning Solutions and Freudenberg

Performance Materials –

have combined their expertise in

technical nonwovens, filter

media and distribution to begin

commercially selling face masks.

These efforts initially centered

on setting up inhouse mask

production in a short space of

time, initially delivering the

needed volumes to Freudenberg

sites. “Our objective was to

fulfill our responsibility to

our employees and society. We

acted quickly, expanded our

capacity and invested in

production equipment for the

manufacture of mouth-nose

masks,” says Dr. Mohsen Sohi,

CEO of the Freudenberg Group.

Freudenberg is limiting sales of

the masks to a maximum order of

two boxes per online customer to

help ensure fair distribution.

In contrast to the now common

industrial and privately sewn

cotton masks, the Freudenberg

masks are made from a high

quality, triple-layered filter

medium.

This filter

medium is made from a high-tech

nonwoven, which is also

manufactured in Germany. The

materials are processed into

masks in newly acquired

production lines launched in

phases at Freudenberg Filtration

Technologies – a first for the

German market. Freudenberg is

planning to expand capacity in

the next few weeks to eventually

allow it to make one million

masks per day in four shifts

around the clock seven days a

week. The technology group will

also continue to deliver media

for the production of face masks

to professional converters and

existing customers.

Currently, efforts are also

underway to produce masks in

North America for the local

market. Japan Vilene Company – a

Freudenberg Business Group – has

been producing masks for the

Asian market, primarily Japan.

However, these products are

subject to individual countries'

COVID-19 export restrictions.

Drylock will Make 100,000 Masks

per day in Spain

Drylock Technologies has

partnered with the Ministry of

Development of the Junta de

Castilla y León in Segovia,

Spain, to create more than four

million surgical-hygienic masks

during the next three months.

The masks will be distributed to

community groups and

organizations.

The conversations between

Drylock, promoter of the project

called ‘Masks with a soul’, and

the regional government, began a

month ago, allowing the Ministry

of Development time to

acquire specific machinery,

which will leave the Shanghai

airport on May 13.

Drylock, one of the leading

companies in the manufacture of

absorbent intimate hygiene

products, has created a separate

space for the line of

manufacture of this sanitary

material in its Segovian

factory. A 200 square meter

clean room will house a line

able to make 100,000 masks per

day.

Kolmi-Hopen one of Four Major

Manufacturers of N95 Masks in

France

In late March French president

Emmanuel Macron toured the

face-mask manufacturing plant

Kolmi-Hopen, in Saint-Barthelemy-d’Anjou

near Angers, to help reassure

French citizens that the

government is investing and

working to increase output, add

capacity and provide critical

care professionals with the

masks they need.

Kolmi-Hopen, a subsidiary of

Medicom, headquartered in

Montreal, Canada, is one of four

major manufacturers of N95

efficiency level face masks in

France, and will deliver up to

200 million masks in the coming

months. In a statement, Macron

said the government plans to

increase its national output of

masks from 3.3 million to 10

million weekly.

Ahlstrom -Munksio Media Being

Used by French Mask Makers

Ahlstrom-Munksjö products

Reliance SMS 200, Reliance SMS

300, Reliance Dextex 200

and Reliance Dextex 300 have

been declared compatible with

the French requirements for face

masks used by civil servants in

contact with the public. The

material is typically used for

the manufacturing of

sterilization wraps for surgical

instruments. Reliance SMS 200

and Reliance SMS 300 have also

been tested compatible with the

European standard EN 14683,

meeting the performance criteria

of surgical masks.

During May the company will

produce material equivalent to

100 million face masks for civil

servants in contact with the

public such as police officers,

prison administrators and social

workers as well as companies

active in essential sectors such

as food, energy, water and

waste.

“The attainment of this

long-term work for the selection

of our products represents a

moment of collective pride at

Ahlstrom-Munksjö. Our medical

business serves the medical

device market worldwide all year

round, and our agility and

ability to innovate makes us an

ideal partner in critical

situations,” says Lionel Bonte,

vice president of medical

business.

In France, Ahlstrom-Munksjö has

some 1600 employees,

eight production sites, two

global R&D centers and a sales

office. Measured by the amount

of employees, France is the

second largest country of

operations representing 20% of

gross sales.

Battelle H2O2 Decontamination

System Being Deployed at Sixty

Locations

On

March 28, the US Food and Drug

Administration, which assesses

the safety of medical products,

issued its first emergency use

authorization (EUA) for a mask

decontamination technology to

Battelle’s Critical Care

Decontamination System. Then, in

April, the U.S. Federal

Government awarded Battelle a

contract to fund the system’s

deployment to 60 locations

throughout the US, including

sites in Seattle, Boston,

Chicago, and near New York City.

As of April 27, Battelle had

processed tens of thousands of

masks, including more than

30,000 for the Ohio Health

network.

The decontamination process

established in Ohio is just one

example of an

effort to respond to

shortages of N95 masks and other

PPE during the novel coronavirus

pandemic by finding ways to use

disposable equipment more than

once. Although such practices

are not approved for standard

care, the US Centers for Disease

Control and Prevention notes

that mask decontamination “may

be necessary”

when PPE supplies are severely

constrained during a crisis. A

handful of other technologies

have now joined Battelle’s

system on the FDA’s list

of EUAs.

And across the country,

health-care facilities are establishing

their own protocols,

many relying on well-known

disinfection methods like

ultraviolet light and heat, as

scientists work to understand

such methods’ effectiveness and

their long-term effects on

equipment performance.

Lehigh University and St Luke’s

Team to Provide UV Mask

Decontamination

A team from Lehigh University

and St. Luke’s University Health

Network created a system with

powerful ultraviolet

light to kill the coronavirus,

allowing the hospital to

decontaminate and re-use N95

masks.

The challenge was in creating a

machine that could handle a

large number of masks and evenly

bathe them in ultraviolet light,

ensuring they were

decontaminated on every surface.

The unit — 80 inches in diameter

and 5 feet tall, with tubes of

light surrounded by an octagonal

metal cage — was engineered by

Lehigh students and staff and

transported in a pickup truck to

St. Luke’s University Hospital

in Fountain Hill, where it was

assembled. Since April 5, The

hospital has processed 15,000

masks, including those used by

staff at nursing homes and

emergency responders.

The goal was to use enough UV-C

light to damage viruses and

bacteria but retain the

integrity of the N95 masks,

which can be degraded over time

by steam or chemicals. The masks

are hung on a hinged frame that

rotates, making sure both sides

of the mask get a blast of

sterilizing light that comes

from up to 13 cylindrical bulbs

at the center of the machine.

Masks can be zapped five to 10

times before they lose their

shape.

UV Finding Decontamination Uses

on Subways and Buses

The technology is being used

elsewhere to control the spread

of the virus.

New York City’s

Metropolitan Transportation

Authority in partnership with

Columbia University announced

plans to use UV-C lights to

disinfect the agency’s trains,

buses and work areas, according

to the New York Daily News.

Since the light is harmful in

high doses, the subways will

close from 1-5 a.m. for the

cleaning. Columbia researchers

are working on technology called

“far UV-C” that could kill

COVID-19 without harming people,

making it possible to disinfect

subways and buses while riders

are aboard.