Coronavirus Technology Solutions

April 14, 2020

Cummins and Dupont are Working Together to Help

Address the Current Shortage of N95 Masks

U.S Army Research on Face Mask Media will be

Helpful

People Should Not Walk/Run/Bike Close Behind

Each Other

FDA approves ASP H2O2 Decontamination Process

______________________________________________________________________________

Cummins and Dupont are Working Together to Help

Address the Current Shortage of N95 Masks

The need for masks has skyrocketed in recent

weeks due to the global pandemic, and Cummins

will use its NanoNet® Media to help answer that

need.

According to Amy Davis, Vice President of

Cummins Filtration, with many of the world’s

leading mask manufacturers in need of the

critical materials to assemble the masks

and struggling to meet demand, Cummins will

use pre-existing filter technology in

partnership with DuPont to help fill the supply

void.

"Cummins is re-evaluating our supply base and

manufacturing capabilities to identify how we

can support our healthcare professionals who

rely on critical personal protective equipment

to do their jobs," Davis said. "Our NanoNet®

Media can fill a key supply void and help

address the mask shortage facing the United

States and other countries around the world."

The project also aims to provide open source

instructions that other healthcare systems and

groups can use to create their own respirator

masks.

Cummins’ NanoNet® and NanoForce® Media

technology, which uses DuPont’s Hybrid Membrane

Technology (HMT), can typically be found in air,

fuel and lube filtration products used in

heavy-duty diesel engines to prevent long-term

engine wear, but also can be used in the N95

respirator masks worn by healthcare

professionals to filter harmful airborne

particles that can spread COVID-19.

The N95 designation means the respirator can

block at least 95 percent of particles from

entering the wearer’s nose and mouth. When

Cummins’ NanoNet® Media was tested using an

industry standard testing method, it exceeded

the performance requirements for N95

designation. Cummins’ manufacturing facilities

have since provided media samples to mask

manufacturers across the globe to test its

effectiveness.

Stock of Cummins Filtration NanoNet® and

NanoForce® Media technology winding.

While products featuring Cummins’ media will

need to be vetted and approved by the National

Institute for Occupational Safety and Health

(NIOSH), the company is preparing to do its part

to help relieve the burden facing the healthcare

industry.

“We’re working as quickly as possible with

healthcare regulators and other partners to help

certify products with our materials, and prepare

our manufacturing facilities to meet demand,”

added Davis.

The first mask prototypes using Cummins’ donated

media were assembled by University of Minnesota

teams in March as part of an initiative to

provide masks to M Health Fairview and other

Minneapolis-based healthcare systems. As the

COVID-19 outbreak escalated, the University of

Minnesota realized their supply of N95 masks to

protect healthcare workers would potentially run

out in a matter of weeks.

To address this challenge, a

team of designers, engineers,

chemists, surgeons,

anesthesiologist and apparel and

clothing experts from the

University of Minnesota’s

Institute for Engineering in

Medicine; Medical School;

College of Design; College of

Science and Engineering; and

Center for Filtration Research

Consortium (CFR) came together

to address this projected

shortage of critical personal

protective equipment.

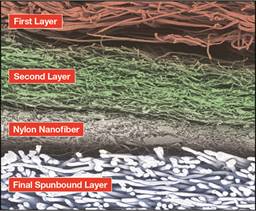

Advanced, high-performance media for N95

respirator manufacturing.

"The first thing we recognized from our experts

in the Center for Filtration Research, who work

directly with Cummins, is that not all

filtration materials are created equal and that

the Cummins material is an excellent

alternative," said Jakub Tolar, Campus Health

Officer and Medical School Dean at the

University of Minnesota.

"We are tremendously grateful for the generous

donation from Cummins of their filtration

materials toward our mask effort. Since the

arrival of the filtration media, we have been

able to make rapid progress, and we now believe

we have several viable mask options, including

both a disposable and re-usable option. These

designs show real promise in keeping our

healthcare workers safe should standard medical

supplies of N95 masks no longer be available,”

continued Tolar.

While DuPont’s innovative and unique Hybrid

Membrane Technology (HMT) is typically

integrated with Cummins’ synthetic fibers to

protect sensitive engine components, it has

multiple other applications that can include

filtration media used in N95 respirator masks.

DuPont’s Hybrid Membrane Technology goes beyond

the limits of traditional semi-porous or

nonwoven membranes for air and liquid

filtration. Made using a proprietary spinning

process, the hybrid technology materials are

comprised of continuous sub-micron fibers. The

end result is a “membrane-like” sheet structure

that balances breathability and high filtration

efficiency of particulates.

“We are proud to make our advanced technology

available to help protect more caregivers on the

front lines of this global health crisis,” said

HP Nanda, Global Vice President & General

Manager, DuPont Water Solutions.

“We thank our partner Cummins for transitioning

the use of its production line to help address

the global shortage of N95 mask materials, and

we thank the experts at the University of

Minnesota for their leadership in testing and

designing several mask options for the benefit

of many healthcare systems," Nanda added. "By

working together—and innovating new applications

of existing technologies and materials—we hope

to slow the spread of this terrible virus."

U.S Army Research on Face Mask Media will be

Helpful

The U.S. Army Edgewood Chemical Biological

Center (ECBC) Respiratory Protection Branch

members investigated novel aerosol filtration

materials for inclusion in the next generation

respirator. Commercial particulate filtration

technologies with high-efficiency and

low-pressure drop have the potential to provide

improved protection to the Warfighter while

decreasing breathing resistance and thus

reducing physiological burden.

A pressure drop of ≤5 mmH2O was selected as the

goal for the development of next generation

lower burden filters.

The aerosol filtration penetration requirement

for the M61 filter is ≤0.01% (i.e., 99.99%

efficiency) when measured at a constant flow

rate of 25 L/min (equivalent to 50 L/min through

the pair of filters). Each filter has an

effective airflow area of approximately 60 cm2 ,

which results in a face velocity of

approximately 7 cm/s when measured at 25 L/min.

The particulate filter element of the M61 filter

consists of pleated HEPA media and is roughly 6

mm thick. The market survey was limited to media

with the potential of achieving efficiencies

≥99.97% (HEPA quality).

While this target is below the JSGPM

requirement, efficiencies of 99.99% can be

achieved through pleating the media, which

reduces the face velocity and increases the

collection efficiency of the filter. This

reduction in face velocity increases the

collection efficiency of the filter. In the case

of flat sheet electrets (nonwoven electrostatic

charged media), the thickness can be increased

to meet HEPA requirements. Efficiency can be

improved by other means to maximize the

effective surface area, for example, by using

larger and more efficient filter designs similar

to those being considered for future integrated

respirator/helmet systems.

To avoid eliminating promising media, the market

survey did not take into consideration the

thickness of the media; however, a total

effective surface area of 250 cm2 was used as

the basis for the 5 mmH2O pressure-drop goal to

take into account the increased surface area

realized by the emerging advanced filter

designs. Taking these goals into consideration,

a market survey was conducted to identify new

HEPA quality filtration media with equivalent or

greater capture efficiency and lower pressure

drop than the particulate media currently used

in military air-purifying respirator filters.

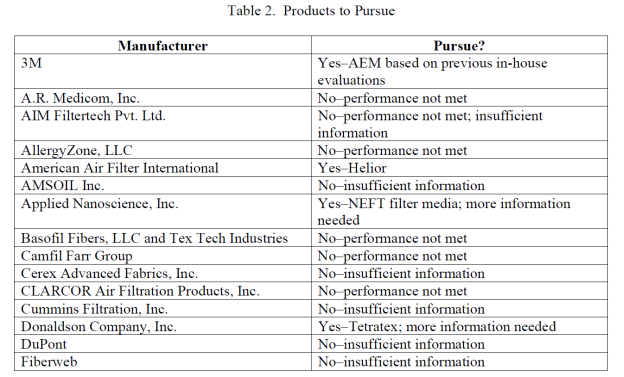

Only commercial manufacturers were considered.

Here are the conclusions.

People Should Not Walk/Run/Bike Close Behind

Each Other.

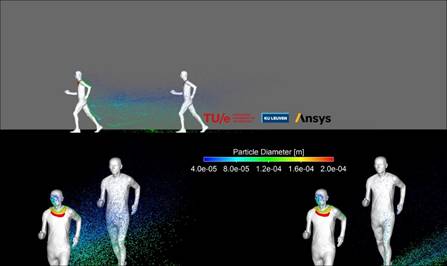

As you can see from the depiction virus mists

can travel through the air from one runner to

another.

The typical social distancing rule which many

countries apply between 1–2 meters seems

effective when you are standing still inside or

even outside with low wind. But when you go for

a walk, run or bike ride you better be more

careful. When someone during a run breathes,

sneezes or coughs, those particles stay behind

in the air. The person running behind you in the

so-called slip-stream goes through this cloud of

droplets.

The researchers came to this conclusion by

simulating the occurrence of saliva particles of

persons during movement (walking and running)

and this from different positions (next to each

other, diagonally behind each other and directly

behind each other). Normally this type of

modelling is used to improve the performance

level of athletes as staying in each other

air-stream is very effective. But when looking

at COVID-19 the recommendation is to stay out of

the slipstream according to the research.

The results of the test are made visible in a

number of animations and visuals. The cloud of

droplets left behind by a person is clearly

visible. “People who sneeze or cough spread

droplets with a bigger force, but also people

who just breathe will leave particles behind”.

The red dots on the image represent the biggest

particles. These create the highest chance of

contamination but also fall down faster. “But

when running through that cloud they still can

land on your clothing” according to Professor

Bert Blocken.

Out of the simulations, it appears that social

distancing plays less of a role for two people

in a low wind environment when running/walking

next to each other. The droplets land behind the

duo. When you are positioned diagonally behind

each other the risk is also smaller to catch the

droplets of the lead runner. The risk of

contamination is the biggest when people are

just behind each other, in each other’s

slipstream.

On the basis of these results the scientist

advises that for walking the distance of people

moving in the same direction in 1 line should be

at least 4–5 meter, for running and slow biking

it should be 10 meters and for hard biking at

least 20 meters. Also, when passing someone it

is advised to already be in different lane at a

considerable distance e.g. 20 meters for biking.

FDA approves ASP H2O2 Decontamination Process

With nearly 10,000 sterilization systems capable

of

processing 480 masks per day and the potential

for

three uses

ASP can be adding the equivalent of 480 x

3 x 10,000 = 1.5 million masks per day for use

by U.S. hospitals.

The U.S. Food and Drug Administration (FDA) has

provided an emergency

use authorization (EUA) for

a decontamination process provided

Advanced Sterilization Products (ASP)

that could see as many as 4 million N95

respirators per day sterilized for re-use.

That’s a significant potential dent in the

ongoing shortage of supplies faced by medical

professionals and frontline workers at

healthcare facilities.

This decontamination process would open up

re-use of N95 masks originally designed for

single use, and it uses vaporized hydrogen

peroxide gas to clean the respirators. ASP’s

STERRAD series sterilization machines, which are

covered under the EUA, are in use in around

6,300 hospitals already (they’re commonly used

for sterilizing other pieces of clinical

equipment but have not previously been intended

for use with N95 masks) and there are around

9,930 in operation across the U.S., each with

the capability of processing around 480 masks

per day.

The FDA has previously cleared another similar

system for N95 decontamination: Battelle’s

vaporized hydrogen peroxide process.

This new clearance greatly expands the reach and

potential volume of decontamination that’s

possible and should pave the way for others to

follow.

ASP

sterilization systems are used with many

hospital devices. Jeremy Yarwood, VP of research

and development says that all sterilization

systems and disinfectant solutions that ASP

provides have been tested against enveloped

viruses, the family of viruses that includes

coronavirus. Furthermore, some of our

products, including CIDEX® OPA,

have been directly tested against coronavirus,

and have been demonstrated to be efficacious.