Hot Gas APC Markets, Decision Groups and SMUEs

The Hot Gas webinar on November 8 provided a good forum to discuss the impact of

IIoT on the hot gas air pollution control market. This included the role of

subject matter experts and groups to provide the needed Industrial Internet of

Wisdom (IIoW) to empower IIoT. The subject matter expert interacts with a

focused group to then become a subject matter ultra-expert (SMUE). The specific

example was the dry scrubbing systems as two NAES plants.

Bob McIlvaine provided a market forecast for hot gas air pollution control the

second speaker was Peter Spinney who made some important points relative to

combustion optimization software based on decades of experience and as a founder

of NEUCO which is now part of GE. These

systems can achieve:

.

Boiler

efficiency increase of 0.5-0.75%

.

CO controlled to desired limit

.

Better ramping and load-following performance

.

Reduced opacity excursions

.

Avoided tail-chasing behavior

.

Better adherence to fan and mill amp limits

.

Improved situational awareness and process insight

NOx control optimization software can

.

Reduce Reagent Usage

.

Lengthen Maintenance Intervals

.

Avoid Ammonia Slip

.

Reduce risk of Ammonium Bisulfate & Sulfur Trioxide deposits

.

Control "Blue-Plume" Opacity Excursions

.

Tighter, condition-based gas temperature control

.

Better Manage System Interactions

Peter is by all criteria a subject matter expert on solid fuel combustion

optimization. If an international decisions group on this subject is formed and

Peter is an active participant, he will become a subject matter ultra-expert.

Another individual of equal stature in the webinar Wednesday was Richard

Thompson of FERCo. In McIlvaine Coal-fired Decisions, there are 28

articles covering FERCo presentations including several on

In Situ Determination of Catalyst Activity,

which will be an important tool in remote monitoring and participation by the

catalyst suppliers.

Relative to combustion optimization FERCo

So if both Peter and Richard participate in the group designated CD 15 below,

they would both contribute and receive insights.

Jeff DeNigris of Malvern discussed the use of their Insitec

particle analyzer system to determine the sorbent size after grinding. It is

economical to buy granular trona and then to mill it on site. The particle

size is critical to SO2 capture. The online analyzer provides key

information to the remote O&M operator. Other uses include activated carbon for

mercury capture.

He also briefly discussed automated measurement of charge neutralization

potential for flocculation in scrubber wastewater treatment. So Malvern is

involved in both the slurry measurement (M2) and free flowing solids measurement

(M3).

Crane Fluid Handling

was also a participant. Two webinar blogs were excerpted to show insights on

slurry valves and pumps. Jake Spence of Crane analyzed designs.

"Another important part of a slurry pump is its casing, which handles all of the

pressure. Slurry pump casings should have larger gaps between the impeller and

the cutwater tongue to reduce wear and to prevent large solid particles from

getting stuck. Because of the additional space, there is more recirculation

inside a slurry pump casing under various operating conditions. Again, this

accelerates wear compared to a typical water pump."

Blogs should be interconnected to groups. In this case it would be a slurry pump

group CD 17. This would also include input from the mining and dredging

industries. McIlvaine has recent TCO comparisons of slurry pumps used in

dredging and mining because larger slower impellers are more expensive but have

less abrasion. Alternatively thicker casings mean longer life.

The final speaker was Stewart Nicholson of Primex. He discussed

the need to separate process decisions from operation and maintenance. In an

organization operating a number of dry scrubbers such as NAES, the

decoupling of process decisions and the utilization of Primex experts to

coordinate them allows NAES to move its operation and maintenance personnel from

plant to plant depending on demand and the price of fuels. One of two coal-fired

power plants may be down but the gas turbine plant operating 24/7 if the gas

price is low. Primex is working toward becoming the process management supplier

for the range of processes within both solid fuel and gas-fired power plants.

Relative to dry scrubbers, Primex has become an SMUE by founding a group of dry

scrubber users (DSUA) and then continuing to participate in this group. NAES has

achieved large reductions in operating costs with the following activities from

Primex and the remote monitoring system based on OSIsoft software. The big

feature of the process management is facilitating action and achieving results.

Primex provides weekly, monthly, and quarterly interactions with the plants.

Weekly

.

Interprets Data to assess Critical System Parameters

.

Provide "First Layer" Diagnosis & Troubleshooting

Monthly

.

Report & Interpret Key Performance Indicators

.

Identify Safety/Reliability/Efficiency Opportunities

.

Recommend & Facilitate Actions

Quarterly

.

Facilitate Onsite Team Meeting

.

Brainstorm & Discuss New Opportunities

.

Update Strategy & Action Plan

The achievement by Primex is noteworthy. Two days of presentations by end users

at the DSUA conference provided convincing testimony to the program value. The

question is now to duplicate this on a large scale.

A decisions group on dry scrubbing can work with DSUA and provide an

international presence. If the group also creates a decision system and conducts

regular webinars, it will be valuable to dry scrubber user 10,000 miles away as

well as to one within easy travel distance.

IIoW is going to require significant expenditure and innovative thinking to be

fully successful. IIoW also will require investment and innovation. It is

unclear who should fund the groups and how the groups should be organized.

There will be a large number of groups needed to create IIoW. Here are just some

of the ones relevant to dry scrubbing. The names in red represent speakers or

contributors to the discussion. The numbers in green represent subject

areas where decision groups and subject matter ultra- experts are needed.

|

Interconnection of

Organizations, SMUEs and

Decision Groups - Dry Scrubbing

example |

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Process SMUE |

Primex |

|

|

|

||

|

|

|

|

|

|

Dave |

Jankura |

|

|

|

|

|

|

|

|

|

Emerson |

|

|

|

|

|

Ams |

|

Data

Analytics |

XlMR |

CD 12 |

|

Process Management |

CD

13 |

|

Combustion

Optimization |

Spinney |

||

|

|

|

|

|

CD14 |

|

|

|

|

CD15 |

Ferco |

|

|

|

|

|

Control |

Rockwell |

|

|

|

|

|

|

|

|

|

|

Dry Scrubbers |

SD

1 |

|

|

|

|

|

|

|

|

|

ID 1 |

ID

2 |

ID

3 |

ID

4 |

|

|

|

|

|

|

|

|

|

Systems

GE, B&W |

SD 2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Spray Drier

GE, B&W |

CD

1 |

|

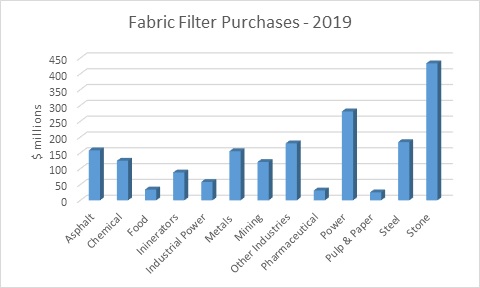

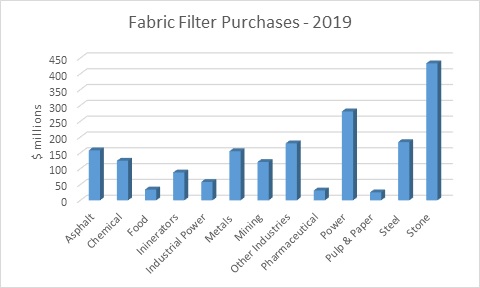

Fabric filter

GE, B&W |

CD

5 |

|

Flow |

|

|||

|

|

Bete |

|

|

|

|

|

|

CD9 |

CD10 |

CD11 |

|

Nozzles |

Spraying

Systems |

CD

2 |

|

Bags

FLS |

CD

6 |

|

Fans

|

Pumps |

Valves |

|

|

Atomizer |

GEA |

CD

3 |

|

|

|

|

|

CD16

Howden |

CD17

Crane

|

Fujikin

Crane

Samson |

|

|

|

|

|

Media

Lydall |

CD

7 |

|

Measure |

Weir |

CD 18 |

|

|

Lime |

Lhoist |

CD

4 |

|

|

|

|

|

M1 |

M2 |

M3 |

|

|

Novinda |

|

|

Fibers

Evonik |

CD

8 |

|

Promecon |

Malvern |

Malvern

FERco |

|

Subject matter experts become subject matter ultra-experts (SMUEs) based on

maximum utilization of the decision insights created by the group. There are

100s of subject areas which warrant decision groups and SMUES. They all should

interconnect with each other.

|

Decision Groups and Subject Matter

Ultra-Experts |

|||

|

Title |

Description |

Title |

Description |

|

CD 1 |

Spray driers, DSI, CFB |

CD12 |

Data analytics |

|

CD2 |

Slurry nozzles |

CD13 |

Process Management systems |

|

CD3 |

Atomizers for food, environmental |

CD14 |

System control components |

|

CD4 |

Calcium reagent decisions |

CD15 |

Combustion optimization systems |

|

CD5 |

Hot gas fabric filters (RA, pulse jet) |

CD16 |

Hot gas fans |

|

CD6 |

Hot gas filter bags |

CD17 |

Slurry Pumps |

|

CD7 |

Hot gas filter media |

CD18 |

Slurry valves |

|

CD8 |

High temperature fibers /resins |

ID1 |

Coal fired power plant decisions |

|

CD 9 |

Hot gas fans |

Id2 |

Waste to energy plant Decisions |

|

CD10 |

Surry pumps |

ID3 |

Biomass boiler Decisions |

|

CD11 |

Surry valves |

ID4 |

Coke Manufacturing Decisions |

|

SD1 |

Dry Scrubber systems |

SD2 |

Hot gas APC systems |

|

M1 |

Hot Gas measurement and control |

M2 |

Surry Liquid measurement and control |

|

M3 |

Free Flowing Solids Measurement |

|

|

The process SMUEs (ID 1-4) will need to extract the wisdom from all the decision

groups. So the solution to the valve sticking problems in dry scrubber systems

in coke manufacturing plants created by groups M1 and CD18 needs to be

communicated to the process SMUE in group ID4.

We look forward to your comments and suggestions in this unique effort.

You can view the webinar at:

https://youtu.be/qMPMyXWgO98

The full set of power points will be included in

44I Coal Fired Power Plant Decisions

N031 Industrial IOT and Remote O&M

Surry Valves can be one of many valve decision guides

One of the decision groups is for slurry valves. Fujikin lime slurry

valves have been a concern and focus for improved maintenance. The SMUE is

working with the component suppliers for better valve and bag designs.

Primex has redesigned bags due to unique process problems and then licensed the

design to FLS, a major bag supplier.

Mcilvaine contends that the system is flawed when the SMUE has to redesign a

component. (We have an interview with Shell on this subject in our Valve

Insights) The better answer is a decision group on bags and one on slurry

valves. Valve suppliers already have experience with lime and limestone

slurries in other industries besides power. Here is a Crane flow sheet on

limestone slurries in a nickel plant.

A decision group benefiting from the range of slurry experience would be the

best approach to the spray drier lime slurry valve problem.

High Performance Valves Role in IIoT and Remote Monitoring

If general purpose valves are the foot soldiers of IIoT then high performance

valves belong in the armoured division. Their performance is much more

critical to the outcome of the battle to improve plant performance. IIoT

promises to revolutionize industry but only if it is accompanied by IIoW

(Industrial Internet of Wisdom). Decisive classification of high performance

valve applications, valve designs, and materials is critical to IIoT success.

High performance valves are defined and the program is explained at High

Performance Valve Classification Program

Background articles and presentations are found in the Mcilvaine Global Decision

Orchard under High

Performance Valve.

If you prefer to view by company, application or process click on Full

Display

Specific Initiatives

Four Severe Service Valve Decisive Classification Analyses are presently being

assembled. We invite contributions for any of them. Please send your comments

to Bob Mcilvaine at rmcilvaine@mcilvainecompany.com

Choke Valves in Oil and Gas

The choke valve market ranges between $250 million and $400 million per year

depending on the definition and where we are in the oil and gas cycle. A

significant portion of choke valve sales are to oil and gas companies. The

definition also has a major effect on the revenue determination. The terms

choke, control and axial are used in different ways. With some

definitions, the market is much larger than with others. Here are some ways the

term is defined:

·

Flow path: Angle most important - if it is axial it is control, if it is angle

it is choke.

·

Trim: If one type of trim is used it is most suitable for choke, if

another it is for control.

·

Location: If it is extraction it is choke, if it is other applications it

is control.

·

Valve type: For some valve suppliers "choke" is just one of a number of

applications and not a type of valve.

With remote monitoring and IIoT evaluation of choke valve performance it is

important that the relevant decisive classification of applications, valve

types, and materials be clarified. This is an ongoing project. To

view the questions and present status click on: Choke

Valve Decision Guide

Power Industry Steam Valves

There are similarities and differences in the steam cycle valve requirements for

nuclear, ultra-supercritical coal, supercritical coal, and gas turbine combined

cycle plants. What sizes are required? What valve types are

recommended for each application What is the appropriate support (trunnion,

floating or a unique design)? What materials are best for base load and

rapid cycling applications? Power

Industry Steam Valves

Oil and Gas Gate Valves for greater than 5000 psi service

Subsea and shale applications are where one finds most of the gate valves with

requirements for greater than 5000 psi service. What are the specific

applications, gate valve designs, and materials which are best for each specific

application? This analysis is in the early stages. We have identified some

suppliers and their products and are asking them for comments. We welcome

input from all sources. Oil

and Gas Gate Valves Greater than 5000 psi Decision Guide

Rising Stem Ball Valves

Rising stem ball valves are used in the oil and gas industry as well as in

petrochemical plants. This analysis initially only has details on valves used

more switching molecular sievers. At this time there is only a partial

analysis suppliers. We need your input relative to additional

applications, additional suppliers, and input on valve sizes and cost.

Rising

Stem Ball Valves

Molecular Sieve Switching Valves

Many valves have been used on this service but few are performing as might be

wished. Three valve designs are usually found in molecular sieve unit switching

valve service: (1) metal-seated ball valves; (2) metal-seated, triple off-set

butterfly valves; and (3) metal-seated, non-contacting, rising stem ball valves.

Some rotary valve options such as the triple offset butterfly valves are

relatively inexpensive to purchase and may perform adequately in the near term.

Operators, however, have generally found them to be deficient in sealing

capability, expected service life and total cost of ownership. Process

disruption, high MRO expense and the inability to deliver a minimum of five

years of continuous service between planned shutdowns have all been persistent

negatives.

Historicallythe rising stem ball valve (RSBV) has been used in this application.

But the selection is complicated and depends to some extent on the severe

conditions existing. Zero-leakage carbide coated metal seated ball valves can be

a preferred option in particularly severe service.

With remote monitoring and IIOT evaluation of valve performance it is important

that the relevant decisive classification of applications, valve types, and

materials be clarified. This is an ongoing project. To view the

questions and present status click on: http://www.mcilvainecompany.com/Decision_Tree/subscriber/Severe_Service_Valve_04_14_16.pdf