GAS TURBINE AND RECIPROCATING

ENGINE DECISIONS

UPDATE

September 23, 2016

McIlvaine Company

TABLE OF

CONTENTS

McIlvaine

September 5 Noise Reduction Interview with Dennis G. Aaberg

Clarcor to Become Sole Supplier of Inlet Filtration

Systems for GE’s H-Class Gas Turbines

GE and Tata Collaborate to Reduce Gas Turbine

Manufacturing Cost

Houweling’s will Install Two 4.4 MW GE Engines in BC

Greenhouse

Houweling’s is also Operating GE Engines at is

Camarillo California Plant

PacifiCorp Activities to Receive Special Coverage in

GTRE Decisions

Currant Creek Plant is CHP with Successful Tomato

Growing Operation

Energy Saving Projects at Washington Plants

Dennis Aaberg has recently retired from Cummins Power Generation after a

thirty-seven-year career in noise and vibration control. He is a recognized

expert on the subject and the author of articles appearing in our Gas

Turbine, Reciprocating Engine Decision Guide. During his career, which

began with Onan Corporation before it was purchased by Cummins, Inc. and became

Cummins Power Generation, he worked within the Applied Technology Group to

reduce product noise levels and improve sound quality on small gas and diesel

engines, generator sets, garden tractors, welders, and a variety of other

engine-driven applications. Dennis has also worked integrally with

customers to solve community noise issues, and application noise issues.

Dennis’ acoustical and vibration knowledge has developed through hands on

experience working on engineering projects and research experiments over that

thirty-seven-year period and attending seminars and classes at such higher

education outlets as Massachusetts Institute of Technology, Purdue University,

University of Wisconsin, University of Minnesota, and numerous other seminars

taught by industry experts and data acquisition equipment manufacturers.

Dennis agreed to answer our specific questions.

McIlvaine:

What are the advantages of customizing

silencer solutions?

Dennis:

To provide fairly accurate insertion loss predictions (i.e. within 1-3 dB(A) or

better) for a given internal combustion engine driven product the silencers must

be custom made for each engine driven application because a given muffler will

perform differently for each different engine it is integrated with.

Exhaust silencing systems act as a system with

the engine, so any modeling work must include physical internal dimensions of

the engine exhaust system and engine; along with all the engine operating

parameters. That is partially why when you look in exhaust silencer

manufacturer catalogues you typically see a 10 dB(A) expected exhaust noise

insertion loss range, because it can vary greatly from engine to engine.

Therefore, to custom design a product to meet a strict noise level, several

iterations of modeling, analysis, test, and validation typically need to be

made. This can be time-consuming and expensive, but perhaps necessary in

critical noise control applications; which are becoming much more common

globally.

Since the speed of sound changes with

temperature, this can also complicate the expected insertion loss of the muffler

for any particular engine because the broadband effectiveness of the silencer

can vary as the engine exhaust temperatures change as the silencing

effectiveness at various frequencies can change as the engine and silencer

temperatures change.

That is why reputable design and test facilities

allow and engine to stabilize at each load and speed for approximately 15

minutes typically before measuring the sound levels.

McIlvaine:

The CO2 from engines is particularly beneficial for

greenhouses. What noise challenges does this pose?

Dennis:

I am not familiar with using CO2 from engines for greenhouses, but I

do know that emissions regulations are getting increasingly stricter to reduce

CO2 emissions.

Exhaust silencing systems have been, and are

continuing to be developed to reduce exhaust gas emissions. These systems

require extensive design considerations, involve using chemical injections into

the diesel exhaust gas stream, and are very expensive; but they are becoming

available.

McIlvaine:

How do noise regulations vary around the world, and how strict are they?

Dennis:

In North America, sound levels are regulated at property lines. Therefore,

when selling products, the sales force must rely on the company providing

accurate sound levels for the products, and when the capability exists,

predicting sound levels at the property line for the application so they can

avoid any fines or loss of sales due to not being able to meet the noise

regulations. (Side note: I used an environmental noise modeling

program called SoundPLAN for this purpose in several situations. SoundPLAN

is generally accepted globally as the premier software modeling program for this

purpose)

In the European Union, and generally in other

parts of the world, sound levels are regulated at the source: meaning the

products up through 400 kW cannot be sold into the European Union if they exceed

the regulated noise limits, specified in A-weighted Sound Power Level (i.e.

dB(A) Lw, or SPWL).

In India, generator sets for outdoor

installations must be installed in a sound enclosure, and the sound levels

measured 1 meter from the generator set cannot exceed 75 dB(A). This is

regulated by their Pollution Control Board.

Noise is increasingly becoming a more sensitive

issue globally and regulations globally are driving acceptable noise levels

lower. Therefore, going forward companies selling products that are

regulated by noise ordinances, regulations, and laws will want to invest in

staff, equipment, and software to effectively and efficiently design their

products with high confidence levels that their final production products will

meet the required sound levels in the markets they plan to sell in to.

McIlvaine:

What are some noise reduction considerations for recreational vehicles and

boats?

Dennis:

Everything has natural frequencies that they like to vibrate at, including

humans. When input forces match the natural frequencies things go into

what we call resonance. These are frequencies where energy is easily

transferred and accepted and can cause the vibrating object to move violently

and fatigue sometimes very quickly and break. At the very least, it will

cause more than usual noise caused by the vibration, since sound is simply

pressure variations caused by vibration in an elastic medium. The higher

the levels of vibration: the higher the noise level.

Recreational vehicles and boats tend to have

large lightly damped structures that like to vibrate at low frequencies.

Generator set primary operating speeds many times line up closely with these

natural frequencies so great care must be exercised in the placement of the

generator set and providing a large impedance mismatch between the generator set

and boat or recreational vehicle structure to provide the isolation necessary to

keep the energy transfer to a minimum. This is usually a challenge and can

be very difficult.

If not critically isolated or if placed in a

part of the structure that is particularly receptive of force inputs, the

vibration forces entering the structure can easily travel from one end of the

structure to the other and cause unacceptable sound and vibration levels inside

to the horror of the people inside the vehicle or boat. As with all

applications, this is a system problem that is best resolved by manufactures of

the boats, recreational vehicles, and generator sets working together to solve

the system problem effectively and efficiently as possible. This can be a

challenge, but is the best approach.

McIlvaine:

What about sound quality? When does that become a

factor?

Dennis:

Sound quality over the past twenty years or so has become increasingly more

important in Consumer Product Markets, such as the recreational vehicle and

marine applications. I have witnessed cases where overall sound levels of

a product acceptable to the customer are higher in amplitude than ones that are

not acceptable simply due to the quality of the sound.

Increasingly owners of recreational vehicles and

boats are saying they don’t want to hear their generator set operating.

They want to flip a switch and get power but not the noise of the generator set

to go with it. As with most things, we want everything, but we are only

willing to pay for so much. This is where sound quality becomes especially

important. If we can improve the quality of the sound to be unobtrusive

even though audible, the customer is willing to accept that.

I might also add that it is possible to design

an application in such a way that the generator set would be silent in respect

to the natural ambient sound levels, but it requires larger sound enclosures,

and almost certainly use of “active sound and vibration systems” that cancel the

acoustic and vibration signals going into the structure by monitoring the signal

and sending a signal back 180 degrees out of phase to cancel it. Since

active cancellation systems are still fairly expensive as compared to passive

systems, most customers are not willing to pay for that increase noise

attenuation yet, but the option exists.

Also, since internal space availability in boats

and recreational vehicles is a premium for customers, they are not yet willing

to sacrifice the space for less noise. Perhaps in the future this will

change as the population gets progressively accustomed to lower noise levels in

the environment. As with everything in life, as higher expectations are

satisfied it just drives expectations even higher.

McIlvaine:

What are considerations for engines and generator sets installed inside a

building or on a building’s roof?

Dennis:

If installed in buildings, the primary considerations are air flow silencing for

the room inlet and outlet air systems. Typical installations have the

generator sets mounted on isolation springs of properly designed stiffness to

reduce vibration energy from transmitting through the floor to the building

structure: or in the case of roof-mounted generator sets, transmitting through

the roof to the building structure.

If installed in a building’s room, the wall mass

usually provides the necessary transmission loss, especially if the walls are

sand-filled, which they many times are to provide the extra mass and damping

needed for good sound transmission loss.

Another consideration is the exhaust silencer

system. These systems typically are designed to run vertically above the

building’s roof level, so they must consider the backpressure produced in

overcoming the pressure to push the exhaust gases up the silencer’s piping

system and how that affects the generator set’s available power output.

McIlvaine:

There seem to be a variety of designs, costs, and performance of sound

enclosures. What tips do you have for purchasers?

Dennis:

There are a wide variety of sound reduction enclosure offerings depending on the

installation sensitivity to sound.

The very basic sheet metal enclosure that is

meant to simply protect the unit from the weather may have louvered openings all

around and no sound reduction materials or sound reduction ductwork. These

relatively flimsy enclosures, in vibration terms, may even increase noise levels

because they are not designed to be noise reduction enclosures, and they will

typically vibrate enough to cause an increase in overall sound level, or at

best, provide no sound attenuation.

Above that, there are typically several levels

of noise reduction offerings based on application needs. These range from

approximately 10 dB(A) reduction to over 20 dB(A) reduction or more in the case

of well-designed drop-over sound enclosures that provide the necessary space to

design high transmission loss walls and high noise reduction air inlet and

outlet ductwork. A 10 dB(A) sound attenuation enclosure with sound

absorption material, a medium grade exhaust silencer, and relatively

unsophisticated air inlet and outlet ductwork for air-flow is usually attained

without much effort.

I must add, however, that all sound attenuation

enclosures must be designed, tested, and analyzed by competent engineering staff

to ensure especially that the cooling capacity needs of the generator set are

maintained to prevent overheating and reduced power output.

McIlvaine:

Can cooling systems add to the noise problem in an enclosure?

Dennis:

As power density increases in generator set products, cooling system packages

are many times producing higher sound levels than the generator set

(engine/generator). This has resulted in the difficult position of

providing a sound enclosure in a reasonable skid-mounted size that can

effectively reduce the noise of the cooling system, which tends to generate high

sound levels at typically low blade-pass frequencies that can be difficult to

attenuate without long acoustically treated air flow ducts.

This is another reason why companies producing

such products can benefit from a staff with good acoustical sound attenuation

knowledge, state-of-the-art data acquisition and analysis equipment, acoustical

modeling expertise, and facilities capable of performing accurate acoustical

measurements in accordance with ISO requirements and recommendations.

McIlvaine:

Any other tips for sound enclosure purchasers?

Dennis:

Keeping in mind that sound is vibration in an elastic medium, and the fact sound

enclosures have large, flat, and usually lightly damped structures, enclosures

are especially susceptible to any vibration paths from the generator set to the

sound enclosure and skid base they are mounted to. Short-circuit paths can

greatly reduce the effectiveness of an otherwise well-designed sound enclosure.

Short-circuits include anything that connects

directly from the operating generator set to the enclosure: such as ground

cables, stiff hoses, exhaust piping touching walls they pass through, vibrating

cables, any compression points between acoustical sound absorption insulation

and the generator set, and etcetera.

Excessively stiff isolation mounts between the

generator set and skid base is another factor. The isolation mounts should

be as soft as possible while still providing sufficient load capacity.

Orientation and location of the isolation mounts can also be a significant

factor.

Skid base stiffness is also an important

consideration. It is prudent to determine the natural frequencies in the

skid base and design a skid base with proper stiffness to avoid natural

frequencies that coincide with the operating frequencies produced by the

generator set.

Clarcor has entered into a ten-year agreement with GE to

become the sole filtration supplier to its H-class power turbine.

The agreement also has provisions for Clarcor to work with GE in

developing the next generation air inlet filtration system for the H-class

platform. GE’s H-class gas turbine

is one of the world’s largest and most efficient turbines in the business.

Clarcor had acquired the air filtration business from GE in December

2013, and it has worked for nearly a year to clinch this deal.

Clarcor will be

providing filters and other components to GE at a discount to cost.

The company expects to realize a sizable aftermarket benefit starting

four years after the sale of the original equipment.

Powerphase, a developer of upgrades for gas turbines, has

been issued a U.S. patent for a technology that improves the output, fuel

efficiency and responsiveness of gas turbines operating at high ambient

temperatures or elevations.

The technology, Turbophase, uses a fuel driven engine and

its waste heat, along with a highly efficient compressor in a cogeneration

process to generate hot, compressed air approximately 35 percent more

efficiently that the gas turbine itself.

The highly efficient air is then injected into the gas turbine, allowing

it to produce its optimum output in all ambient conditions.

Because the incremental air is created so efficiently, not only does the

gas turbine generate more megawatt hours, but it also makes all of its megawatt

hours more fuel efficiently.

The company has installed Turbophase on the two most widely

used gas turbines, the 6B and the 7FA, both manufactured by GE.

Because all gas turbines use copious amounts of air in their combustion

processes, greater air efficiency leads to greater fuel efficiency.

"Our innovative use of air creates a generational leap is

gas turbine fuel efficiency,” says Bob Kraft, the inventor of Turbophase.

“We like to say, 'Air is cheaper than fuel.'"

GE and Tata Consultancy Services have developed a

technology that will revolutionize the gas turbine manufacturing process using

smart LEDs and GE’s Predix operating system.

The solution will analyze temperatures at various points on the metal

turbine parts as they are assembled and cooled, allowing operators to know when

the next operation can be performed, reducing wait time between operations and

improving quality monitoring. A pilot application has been built at GE Power’s

gas turbine manufacturing plant in Greenville, South Carolina.

During the turbine manufacturing process, rotor stacking is

a key process and needs extremely high levels of precision.

If the rotor wheels are stacked incorrectly due to differences in the

surface temperature, it will require reassembly, incurring heavy additional

costs and two to three weeks of shipment delays.

Tata’s new digital solution provides automatic data collection of ambient

room and rotor surface temperatures, notifying workers when the next operation

may proceed and alerting workers to any non-uniformity.

The platform is composed of smart LED fixtures from

Current, powered by GE, integrated with sensors that monitor temperature,

humidity and any physical object presence, transmitting the data to an Intel

Atom-based gateway where the information is streamed to the Predix cloud.

GTRE second section

Houweling’s Nurseries Ltd. (dba, Houweling’s Tomatoes)

operates a 20-hectare greenhouse facility in Delta, B.C., producing both fresh

tomatoes and propagated vegetable seedlings for other greenhouse vegetable

growers. The heat and CO2

requirements are supplied by five natural gas fired boilers which have an

estimated efficiency of approximately 84%. The estimated emissions produced by

the current operation of the natural gas fired boilers are 23.7 tons annually.

The boilers operate throughout the day to produce heat

which is stored in a 1.5-million-gallon reserve tank and subsequently used as

required in the greenhouse. Some amounts of the CO2-enriched exhaust are used to

promote a healthy crop and vegetable production.

An additional 1,000 tons of liquid CO2 is purchased for their

seedling propagation department, as the CO2 generated from the

current system is not acceptable for growing seedlings.

This limitation creates additional waste during the months

of October to February as crop production is reduced and seedling propagation is

at its peak production. During this

period the boilers are only in operation for heating generation. As a result,

the exhaust from the boilers is released into the atmosphere, while liquid CO2

must still be purchased.

Houweling’s Tomatoes proposes the installation of two 4.4

MW GE Jenbacher natural gas-fired, combustion engine driven, cogeneration units.

The CO2 enriched gases from the engines will be treated using

selective catalytic reduction (Hanwel COdiNOX system) to reduce the NOx

levels in the exhaust, meeting the requirements of the seedling crops as well as

promoting healthy crop enhancement in the tomato production area. This flue gas

cleaner ensures the flue gases from CHP gas engines are converted into food

grade CO2, which can then be used immediately for plant and seedling

fertilization. This will eliminate the need to purchase, transport and store

liquid CO2. The anticipated emissions from the Co-Gen units will be

less than 11.5 tons annually, reducing emissions output by at least 50 percent.

GE engines have been providing heat, power, and CO2

to a California greenhouse for the last several years. Houwelings Tomatoes, is

operating the first combined heat and power (CHP) greenhouse project in America

that captures carbon dioxide (CO2) for use in plant fertilization.

Using two of GE’s 4.36-megawatt (MW) units, Jenbacher J624 two-staged

turbocharged natural gas engines and a GE-designed CO2 fertilization

system, the plant provides heat, power and CO2 to Houwelings 125-acre

tomato greenhouse in Camarillo, Calif.

GE has installed more than 800 gas engine CHP units in

greenhouses globally. This represents approximately 2 gigawatts of power

generation plus CO2 fertilization systems. With the installation of

Houwelings engines GE has its first U.S.-based system.

The first greenhouse CHP project in the U.S. also gives an

added boost to California’s goal to generate 6,500 MW of new CHP generation in

the state by 2020. The project represents the launch of GE’s J624 two-staged

turbocharged gas engines for the 60 Hz segment and the first of these engines

sold in the U.S. Introduced by GE in 2007; the J624 is the world’s first

24-cylinder gas engine for commercial power generation and can be used in

various applications. It also is the first gas engine featuring double turbo

charging, which makes it even more efficient.

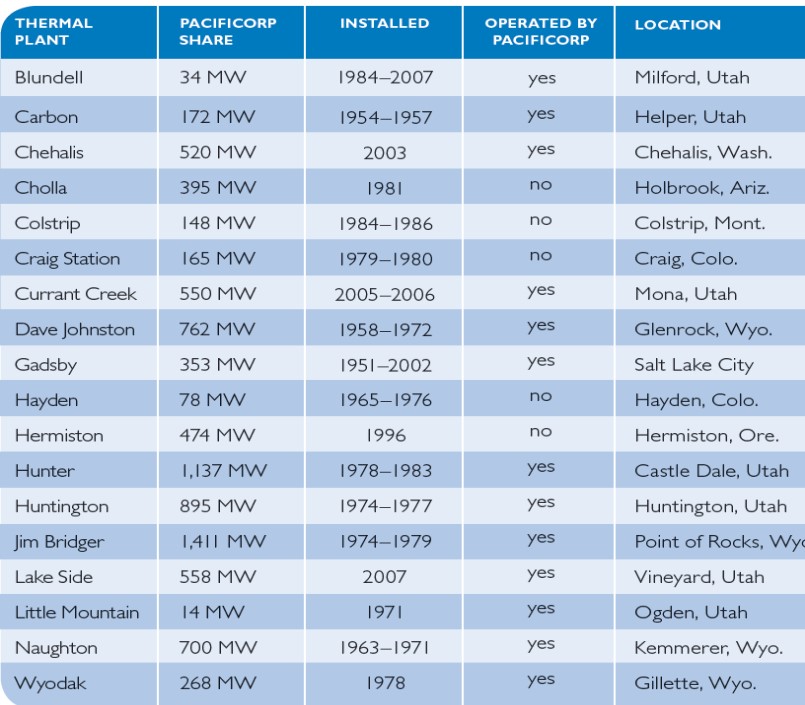

McIlvaine has been conducting a series of five webinars for PacifiCorp to help

them with their decisions on NOx control at coal-fired power plants.

The webinars are organized around the information which is gathered for Power

Plant Air Quality Decisions. This

effort is being expanded to cover activities at all the PacifiCorp power plants.

The purpose of adding information on PacifiCorp gas turbine and gas engine

activities is to demonstrate the value of GTRE Decisions to any power plant

Person

to person communication optimization is just as challenging

as machine to machine. Suppliers and consultants as well as individuals

within PacifiCorp can benefit from the communication regarding

activities at all the plants.

All the newer thermal power plants operated by the company are fueled

with natural gas.

An upgrade was

supplied several years ago. We would like to report on the current status

and include options by one and all on the approach.

The Currant

Creek project is a grassroots 525-megawatt natural gas-fired power plant

consisting of a 2 x 1 combined cycle power block. The plant was constructed in

two phases: Phase 1 consisted of the installation of two GE 7FA combustion

turbine generators to operate in simple cycle mode, and Phase II called for the

installation of two heat recovery steam generators (HSRGs) and a steam turbine

generator.

The two HRSGs

constructed in Phase II were a 10-module tube bundle design. PCL’s work included

installation of the Low Pressure (LP), Intermediate Pressure (IP), and High

Pressure (HP) steam drums, boiler piping, soot blowers, platforms, grating, and

associated equipment.

PacifiCorp entered into a sole source

contract with General Electric International to install its Op-Flex cold day

performance package on the Currant Creek plant. The estimated amount of this

purchase is $7,819,500.

Under the contract

General Electric was to provide three equipment packages designed to increase

the cold weather performance, gas turbine operational flexibility, increase base

load output, and enhance combustion dynamics monitoring at the Currant Creek

plant. The “Op-Flex Cold Day Performance” package is designed to provide

increased output and improved heat rate during cold weather conditions.

The “Op-Flex Turndown” package provides the ability for plant turndown

(reduction in load) to be reduced from 80% to 70%. This package will

result in lower operating costs, increased low load reliability, less fuel

consumption to stay on line, and expanded emission compliance. The

“Continuous Dynamics Monitoring” package enables the first two packages to work.

PacifiCorp said that

they had exhausted competitive alternatives to the engine control packages

offered by General Electric. These packages can only be provided by

General Electric, the original equipment manufacturer and owner of the

proprietary engine control system. Payment for the equipment packages is

based on a sliding scale based on performance. If the unit performance

meets or exceeds the guaranteed performance levels, payment will be at the level

stated above. If unit performance does not meet the guaranteed level, the

payment is reduced accordingly down to a minimum level of $319,500.

If you have any

contributions to update us on this, it would be appreciated.

The Currant creek plant

provides heat and CO2 to a large on site tomato greenhouse. It

involves a large duct providing waste heat and CO2 as shown in the

picture below. It has been quite successful but one Pacific Corp source

said that in the future the hot water from the HRSG a smaller duct with just

enough flow to provide the CO2 would be an even better solution.

A duct connects Rocky Mountain

Power's Currant Creek Plant with the Houweling’s Tomatoes greenhouse. The power

plant heats the greenhouse and it provides nutrients and condensed water to the

tomato plants.

The 28-acre Houweling’s

Tomatoes greenhouse near Mona, Utah, is among the first of its kind in the world

to draw its heat and plant-nourishing carbon dioxide from a neighboring power

plant. A bonus for Houweling’s is the water it condenses from the flue gas is

used to irrigate the tomato plants.

Brad Richards, manager at Rocky

Mountain Power’s Currant Creek Plant explained, “The manufacturer of the boiler

and stack engineered the penetration in the stack and determined there wouldn’t

be any issues with our operations or with our emissions monitoring equipment.”

A plant outage was required to

complete construction of the duct. So Houwelings and Rocky Mountain Power

coordinated the work during planned maintenance on a weekend in April 2015.

The Houweling’s Tomatoes heat

recovery system inside its boiler building connects to the 10-foot-diameter duct

from Currant Creek Plant.

“We’ve been upfront with

Houweling’s from the beginning that our customers are first priority with

everything having to do with safety and plant operations,” said Ian Andrews,

Rocky Mountain Power resource development director. “We had to coordinate a

phased construction process to work around the plant’s planned outage schedule.”

Houweling’s began construction of

the 475-foot-long duct from the plant to the greenhouse in July 2015. The

10-foot-diameter duct stands 25 to 30 feet above the ground.

“We didn’t expect any effects on

plant performance or reliability, and there haven’t been any,” Richards

reported. “The system is working well and was designed with very few changes to

our normal operation.”

Using an Argus control system, waste exhaust is drawn off

the side of the stack, diverting it into Houwelings energy building where

thermal energy is captured and stored for on-demand heat. Condensation from this

process is captured and used to supplement irrigation water, and the remaining

exhaust CO₂ is released directly into the greenhouse to promote plant growth.

The custom Argus system controls the equipment that extracts the CO₂ and the

heat from the stack gas and sends signals to and from the power plant, including

general status, alarm points and portions of dampers, CO₂ demand, boiler status,

and temperature and efficiency readings. The control system also monitors gas

flow and temperature, concentration of CO and NOx, and controls the condenser

fans, condenser pumps and dampers on this project.

Yurij Duda, Argus Controls General Manager congratulated

Houweling’s on the award: “Houwelings is a real leader in sustainable

agriculture and is truly committed to innovation in energy management. Argus was

honored to be selected as their control system partner to help make this unique

project a reality.”

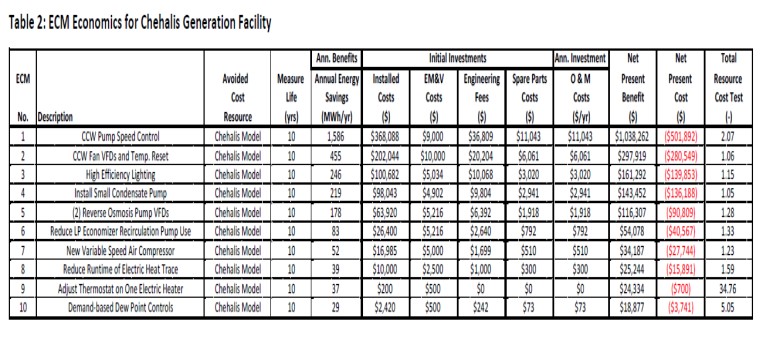

The purpose of a 2011 report

was to outline the systems investigated and detail the cost effective measures

at three of the seven locations: Jim Bridger (Unit #1 only), Chehalis and

Goodnoe Hills. This 2011 report is displayed in full in the PPAQD

Intelligence System.

One of the biggest potential improvements at the time of

the report was adding VFD to pumps and fans. For example, VFD could be installed

at Jim Bridger for RO feed and condensate pumps.

This system consists of three

RO system trains; A, B and C. Trains A and B utilize three 60 HP RO feed

pumps and train C has two 75 HP pumps. Trains A and B use a discharge

control valve to deliver about 270 gpm of filtered water to the RO membranes.

During normal operation two of the three trains are in operation. When

Trains A and B are in operation only 2 of the three pumps are needed.

Train C only needs one of two pumps to operate.

Proposed: RO feed pumps on

Trains A and B should be upgraded with VFDs and controls to vary pump speed to

deliver the required flow to the RO membranes.

This measure would add the

following equipment:

·

Six 60 HP pump VFDs

·

VFD controls

Condensate Pumps

Baseline: The condensate pump system consists of three 700 HP 7,200 volt pumps

that transport condensate from the discharge of the main turbine to the

Deaerator (DA) tank.

During normal operation two of

the three pumps are needed to maintain the tank level in the DA tank. Two

parallel discharge control valves are modulated to the desired DA tank level.

Proposed:

The proposed changes would install new

inverter rated motors with VFDs and necessary controls to regulate the pump

speed. The pump speed will be varied to maintain the DA tank level. The existing

control valves should be fully opened during normal operation.

This measure would add the

following equipment:

·

Three 700 HP 7,200-volt pump VFDs

·

Three 700 HP 7,200-volt inverter duty motors

·

VFD controls

Forced Draft Fans

Baseline: This system consists of two 2,250 HP 7,200 volt centrifugal fans that

operate in parallel to provide secondary and overfire combustion air to

the boiler. Capacity control is achieved by variable inlet vanes. The

fans maintain a static pressure of approximately 16 in WC in the duct.

Both fans are needed during normal operation.

Proposed: The proposed ECM is

to install new 7,200-volt invertor duty motors and VFDs with controls. The

existing inlet vane dampers should be removed and speed control used to meet the

required flow and pressure based on unit load. This measure would add the

following equipment:

·

Two 2,250 HP invertor duty 7,200 volt motors

·

Two correctly sized VFDs

·

VFD controls

Other pumps and fans were included.

Also included is

the analysis for the520 MW gas turbine combined cycle plant located in Chehalis.

Approved gas turbine component supplier list for

PacifiCorp

Preferred vendors based on the

Currant Creek 2 plant are designated. For example, Cuno is the approved supplier

for the condensate filters. However, in 2011 at Wyodak the Pall filter was

installed to replace the existing Cuno string wound filters and positive results

such as less iron deposition were experienced. Has this information been

transferred to those making up bidders’ lists?

Here are new entries in the GTRE Decisions. You can click

on the title for the full text.

Wartsila has many applications in baseload, standby and emergency power

Applications include airport installations with heat, cooling, and power. One

installation is run with vegetable oil as a fuel and does include SCR. CHP

provides up to 90% efficiency.

Revision Date: 9/7/2016

Tags: Wartsila, NOx

Oil & Gas Slides - Hot Topic Hour August 26, 2016

The Oil and Gas webinar conducted by McIlvaine was primarily focused on the

opportunities created by the growth of gas by over 50 quads over the next 25

years.

Revision Date: 8/26/2016

Tags: 221112 - Fossil Fuel

化石燃料, 324110 - Petroleum

Refineries 石油精炼

Oil & Gas Webinar - Hot Topic Hour August 25, 2016

Maximizing flow control and treatment revenues is a volatile market.

Revision Date: 8/25/2016

Tags: 221112 - Fossil Fuel

化石燃料, 324110 - Petroleum

Refineries 石油精炼

Lower emission limits for biogas engines in SCAQMD as of January 2016

SCAQMD rule for biogas effective 2016 limits emissions to 11 ppmv NOx – 30

ppmv VOC – 250 ppmv CO. Stakeholders have commented that the capital and

operating costs for cleaning up the biogas are very high and post-combustion

control technologies such as Catalytic Oxidation and Selective Catalytic

Reduction (SCR) are expensive to install and operate and argued that many of

them will resort to flaring as a less costly alternative. Response: •The costs

are significant but the environmental benefits are also significant. •Proposed

controls are very cost effective. •Reasonable emission reductions such as those

from biogas engines needed to meet the ambient air quality standards. •Flaring

of a renewable energy source is undesirable. •Biogas flaring, except for a small

Greenhouse Gas disbenefit, has a much lower criteria pollutant footprint

compared to biogas engines, even considering power that needs to be generated by

central power plants.

Revision Date: 8/23/2016

Tags: 562212 - Solid Waste Landfill, Regulation,

SCAQMD, Emissions Control

Update as of March 2016: Following the Public Comment Period and Hearing of

July 2015, Microsoft submitted a revised permit application. The revisions are

currently under review. Upon a completeness determination, Ecology will provide

an additional public involvement opportunity for review and comment of the

requested permit revisions. When completed, the Oxford Data Center will contain

four Phase 1 activity zone (AZ) buildings designated AZ-4A, AZ-4B, AZ-4C, AZ-4D;

four core network room (CNR) buildings; an administrative building; and four

phase 2 AZ buildings designated AZ-3A, AZ- 3B, AZ-3C, AZ-3D. Building

construction for the Phase 1 generators and cooling towers began before the end

of 2014. Construction of Phase 2 is expected to begin within 18 months after the

start of generator commissioning for Phase 1. Project Oxford Phases 1 and 2 will

have thirty-two (32) Caterpillar Model 3516C-HD-TA diesel powered electric

emergency generators in the activity zone buildings with a power rating of 2.5

MWe per generator, four (4) Caterpillar Model 3516C-TA diesel powered electric

emergency generators in the CNR buildings with a power rating of 2.0 MWe per

generator, and one (1) Caterpillar Model C27ATAAC diesel powered electric

emergency generator in the administrative building with a power rating of 0.75

MWe. The engines are equipped to meet Tier 1

Revision Date: 8/23/2016

Tags: Microsoft Corporation, Industrial Emitters,

Data Center, Emissions Control

Multiple routes for siloxane removal from biogas

Cormetech cites low permissible levels of siloxane. Wastewater treatment

plants and landfills have higher siloxane levels. A variety of treatment methods

include consumables such as activated carbon, regenerative with resins, and even

chiller/adsorbers.

Revision Date: 8/23/2016

Tags: 562212 - Solid Waste Landfill, Siloxane,

Emissions Control

Johnson Matthey emission control for stationary engines

What is a catalyst? ◦ How does it work? �

Three Way Catalyst (aka NSCR or TWC) for Rich Burn Engines

� Catalyst Components and Operation

� Air-Fuel Ratio Controllers

� Summary

� Two Way Catalyst (aka Oxidation) for

Lean Burn Engines � Catalyst Operation

� Summary

� Selective Catalytic Reduction Systems

(aka SCR) for Lean Burn Engines � What

is SCR? / How it is Different from Two Way and Three Way.

Revision Date: 8/23/2016

Tags: Johnson Matthey, Emissions Control

Tenneco has modular SCR system for ships and locomotives

A team from China, U.S. and Europe has designed a modular SCR system for

ships and locomotives. Successful first applications include a ship in the Great

Lakes and one in the Gulf of Mexico.

Revision Date: 8/23/2016

Tags: 483111 - Deep Sea Freight Transportation,

Tenneco, Modular System, SCR, Emissions Control

EPA cost estimate of NESHAP for SI stationary engines is $115 million /yr

EPA estimates that complying with the reconsidered national emission

standards for hazardous air pollutants (NESHAP) for stationary spark-ignition

(SI) reciprocating internal combustion engines (RICE) will have an annualized

cost of approximately $115 million per year (2009 or 2010 dollars) in the year

of full implementation of the rule (2013). The total annualized costs of the

reconsidered rule are 55% less than those for the final SI RICE NESHAP

promulgated in 2010. Using these costs, EPA estimates in its economic impact

analysis that the NESHAP will have limited impacts on the industries affected

and their consumers. Using sales data obtained for affected small entities in an

analysis of the impacts of this rule on small entities.

Revision Date: 8/23/2016

Tags: Regulation, Emissions Control

China Marine Emissions Analysis by NRDC in 2013

Thirty percent of the world’s ocean going vessels passes through China.

Shipping is the largest NOx and PM generator in Hong Kong. Stringent NOx

controls are presently required for ships entering certain controlled regions in

Europe and the U.S. Many of the ships use high sulfur cheap fuels and need

scrubbers for SO2 removal. McIlvaine raises the question as to

whether the catalytic filter with direct sorbent injection is not the best

answer. A scheduled interview with Tri-Mer and Filtration Group will pose this

question.

Revision Date: 8/23/2016

Tags: 483111 - Deep Sea Freight Transportation,

NOx, Scrubber, Emissions Control, China

Cummins CHP installations for greenhouses have short payback time

CHP for heat and CO2 production for greenhouse applications can

pay back in a remarkably short time, ranging anywhere from 1.5 to 3 years in

favorable conditions says Stefan De Witt of Cummins Engine. Gas-fueled generator

sets are highly suitable for this application because of their excellent

environmental characteristics and their efficient production of heat and

electricity. When implementing a solution, the designer must consider a number

of points. For the dimensioning of the CO2 equipment such as tubes

and fans, for example, it is important to keep in mind the excess air factor,

defined as the amount of air admitted divided by the minimum amount of air

required for the complete combustion of a fuel. The amount of air for complete

combustion of a fuel depends on the composition of the fuel. Combustion of

approximately 35 cubic ft of natural gas at normal temperature and pressure (1 N

m³) needs approximately 8.5 N m³ of air. Lean-burn engines operate at a high

excess air factor (above 1.5) to keep NOx production to a minimum. Consequently,

a CHP unit produces a larger volume of exhaust gases than a burner.

Revision Date: 8/23/2016

Tags: Cummins, Greenhouse

The MTC project will have the capability to provide up to 62.5 MW of

electrical power. The Middletown Technology Center has a projected demand of 50

MW when completed. The other approximately 12.5 MW of capacity represents one 10

MW engine and one 2.5 MW engine that are redundant to the minimum required

number to meet the 50 MW load of the facility. Those two engines are necessary

from a reliability perspective to cover periods when one of the other 10 MW or

2.5 MW engines is out of service for maintenance or repairs. On occasion when

requested by Delaware Municipal Electric Corporation (‘DEMEC”), MTC may export

power to DEMEC during periods of high electricity demand. The project will

contain five Caterpillar C20CM34 and five Caterpillar G3520H natural gas fired

reciprocating engines. Air emissions from the engines will be controlled using a

selective catalytic reduction (SCR) system for NOx control and an oxidation

catalyst system for CO, VOC and HAP control the five Caterpillar C20CM.

Revision Date: 8/23/2016

Tags: Data Center, Emissions Control

Bob McIlvaine

President

847 784 0012 ext. 112

rmcilvaine@mcilvainecompany.com

Click

here to un-subscribe from this mailing list.