GAS TURBINE AND COMBINED CYCLE DECISIONS

UPDATE

September 2015

McIlvaine Company

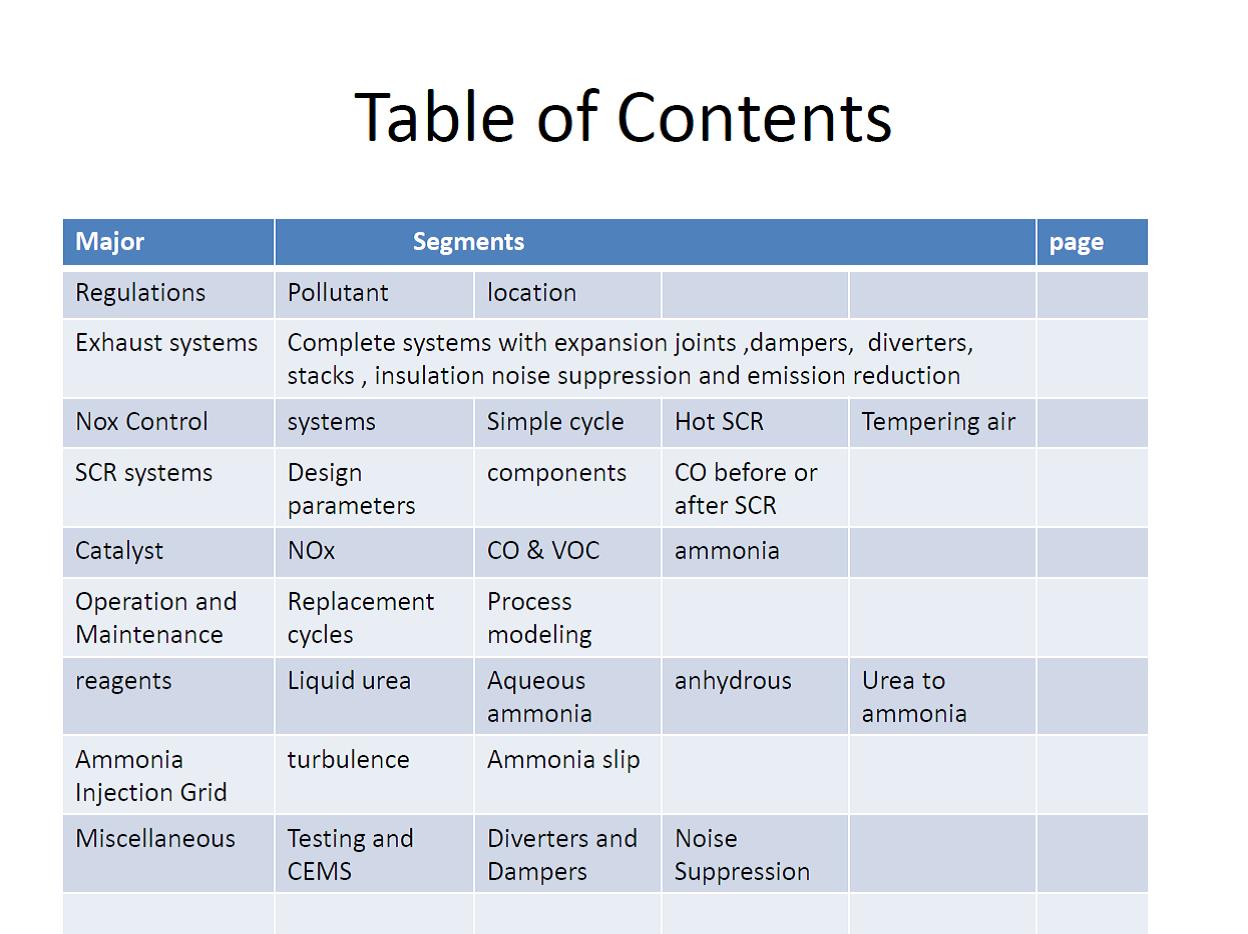

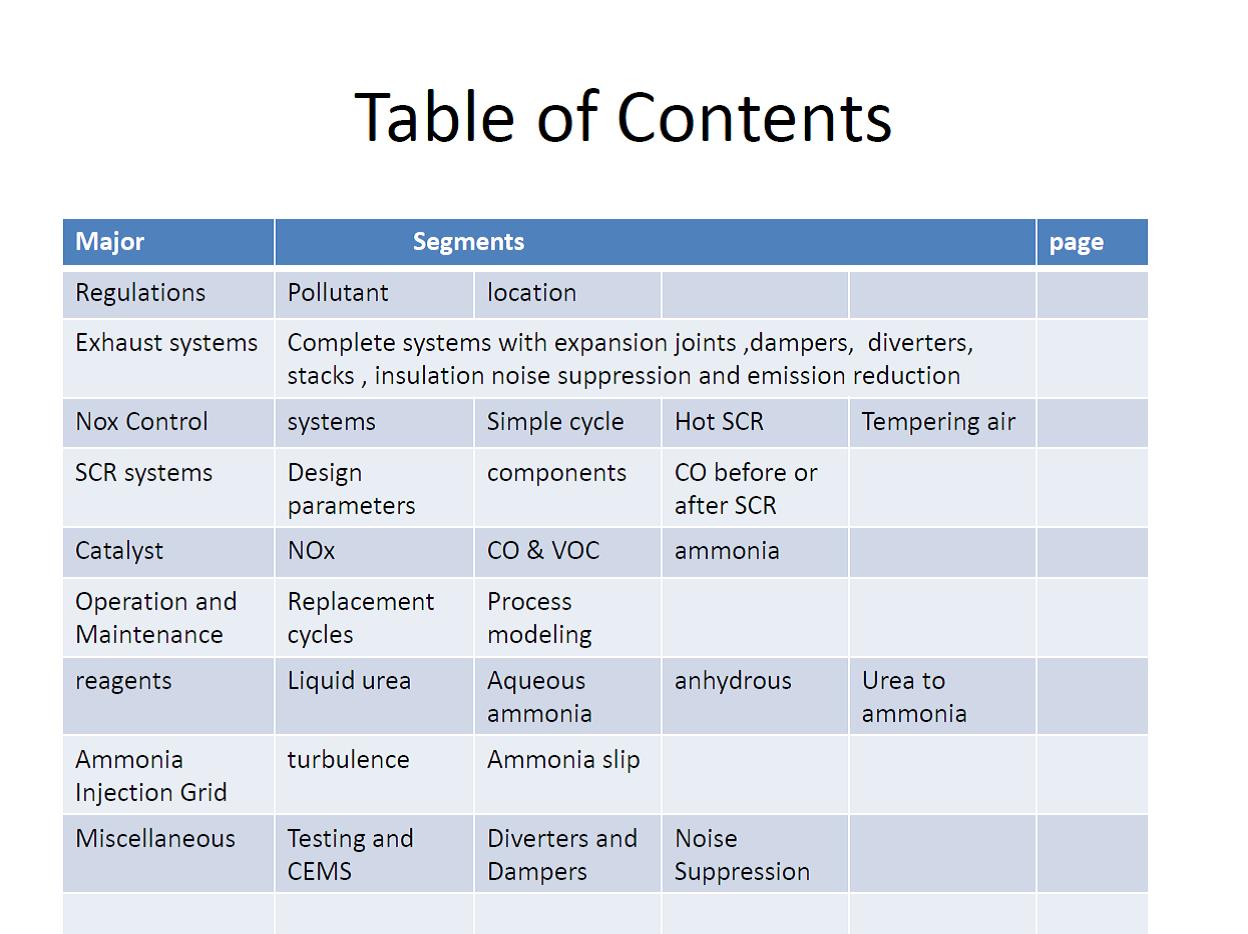

TABLE OF

CONTENTS

Total Solutions Hot Topic Hour (August 20) confirms the

Trend toward Greater Outsourcing

Total Solutions Options - Hot Topic Hour August 20, 2015

The discussion of Total Solution

Options was based on a series of power points.

Revision Date:

8/20/2015

Tags:

Total Solutions Options Webinar - Hot Topic Hour August 20, 2015

Speakers and participants in the

Total Solutions Hot Topic Hour on August 20 confirmed that customers want

suppliers to offer a broader scope of design and installation services. More

operation and maintenance support is also needed.

Revision Date:

8/20/2015

Tags:

Gas Turbine

Exhaust and Emissions Control

Highlights of a hot topic hour

webinar on gas turbine exhaust systems including dampers, silencers, catalysts

and other components focused on unmet needs, issues and options.

Revision Date:

8/20/2015

Tags:

McIlvaine, Gas Turbine, Exhaust System

Gas Turbine NOx Reduction Retrofit

Chevron’s Eastridge Cogeneration

Plant near Bakersfield, California, produces steam for thermally enhanced oil

recovery and electricity to the grid. To meet regional NOx emissions rules, two

existing gas turbines needed the addition of selective catalytic reduction (SCR)

for NOx control. This paper discusses the retrofit process from beginning to

end.

Revision Date:

8/19/2015

Tags:

221112 - Fossil Fuel

化石燃料, Chevron, Peerless Manufacturing,

Ammonia, SCR, Catalyst, Retrofit Technology, Cost, DeNOx, USA

Montrose supplies stack testing, consulting, and laboratory services

Montrose has acquired a number

of companies and supplies a whole suite of environmental services.

Revision Date:

8/17/2015

Tags:

221118 - Other Electric Power , 221118 - Other Electric Power , Montrose

Environmental, Monitoring, Testing, Consulting, Total System Solutions

Sulzer SCR Mixing and Other Mixing Equipment

Sulzer has a range of flow

control and treatment products including a mixer which evenly distributes

ammonia in the ductwork prior to an SCR.

Revision Date:

8/17/2015

Tags:

221112 - Fossil Fuel

化石燃料, Sulzer Ltd., Mixer, SCR, NOx Control,

Ammonia Injection

IAPWS Gives Guidance for Monitoring Steam

Purity

Problems caused by mechanical and

vaporous carryover of contaminants in the water to the steam cycle begin with

deposition and corrosion of HRSG tubes and steam-turbine surfaces and can

ultimately lead to material deterioration, performance deterioration, extensive

downtime for removing deposits, and catastrophic failures. This article gives

guidance for monitoring steam purity to avoid these issues.

Revision Date:

8/11/2015

Tags:

221112 - Fossil Fuel

化石燃料, Corrosion, Cycle Chemistry, Sampling,

Combined Cycle Journal

Upgrading Legacy Gas Turbines to Meet Challenging NOx and CO Permit Limits

At the Clark Generating Station

in Nevada, four gas turbines with diffusion flame burners were commissioned

around 1980 and permitted for 103 ppm NOx. The turbines were converted to dry

low NOx combustors and now operate at less than 5 ppm. This article discusses

what is involved in converting to DLN.

Revision Date:

8/3/2015

Tags:

221112 - Fossil Fuel

化石燃料, NV Energy, Low NOx Burner, NOx Emissions

Reduction, Combined Cycle Journal, USA

Managing the Catalysts of a Combustion Turbine Fleet

Historically, many gas plants

have been operated cyclically with extended dormant periods due to high natural

gas prices and a varying demand for the electricity the plant provides. For

plants with an SCR system, stopping and laying up the equipment may accelerate

aging of the catalyst system components, increasing the importance of

inspections and preventative maintenance planning. This article discusses the

process of economically managing a fleet of SCR-equipped gas turbines.

Revision Date:

8/3/2015

Tags:

221112 - Fossil Fuel

化石燃料, Cormetech, SCR, Catalyst, Maintenance,

NOx Emissions Reduction, Power Magazine

Eliminating Feedwater Control Valve Damage with Multi-stage, Multi-path

Flowserve Control Valves

The feedwater control valve

(located downstream of the high-pressure feedwater heaters) performs the

critical function of controlling the feedwater flow rate over a wide range of

service conditions. During startup and shutdown, the feedwater control valve

restricts flow by controlling near the closed position. The pressure drop across

the valve is high, which can cause severe cavitation and noise. Over time,

these severe service conditions will damage a control valve. Even a properly

designed valve will not work well unless it is connected to a correctly sized

actuator. An undersized actuator will cause unstable flow conditions while an

oversized unit has a slow response to input signals. Flowserve has successfully

addressed these issues with specially engineering multi-stage multi-path, or

MSMP, designs. MSMP trim channels the flow through a series of orifices to

reduce the pressure in stages. This prevents cavitation from occurring inside

the valve. The velocity of the feedwater is kept low to prevent erosion of the

valve body and to reduce noise and vibration. MSMP trim is customer-designed

for the full range of service conditions. MSMP trim prevents cavitation when

throttling near the seat but acts like a conventional control valve when

controlling near the full-open position. As the pressure drop across the valve

decreases, the cavitation also decreases and then stops. To maintain flow rate

with decreasing pressure drop, the valve will open further and expose flow paths

without orifices. The orifices are not needed at this flow condition because

cavitation has stopped.

Revision Date:

8/3/2015

Tags:

221118 - Other Electric Power, 221118 - Other Electric Power, Flowserve, Valve,

Actuator, Boiler Feedwater System, Cavitation, Noise, Vibration

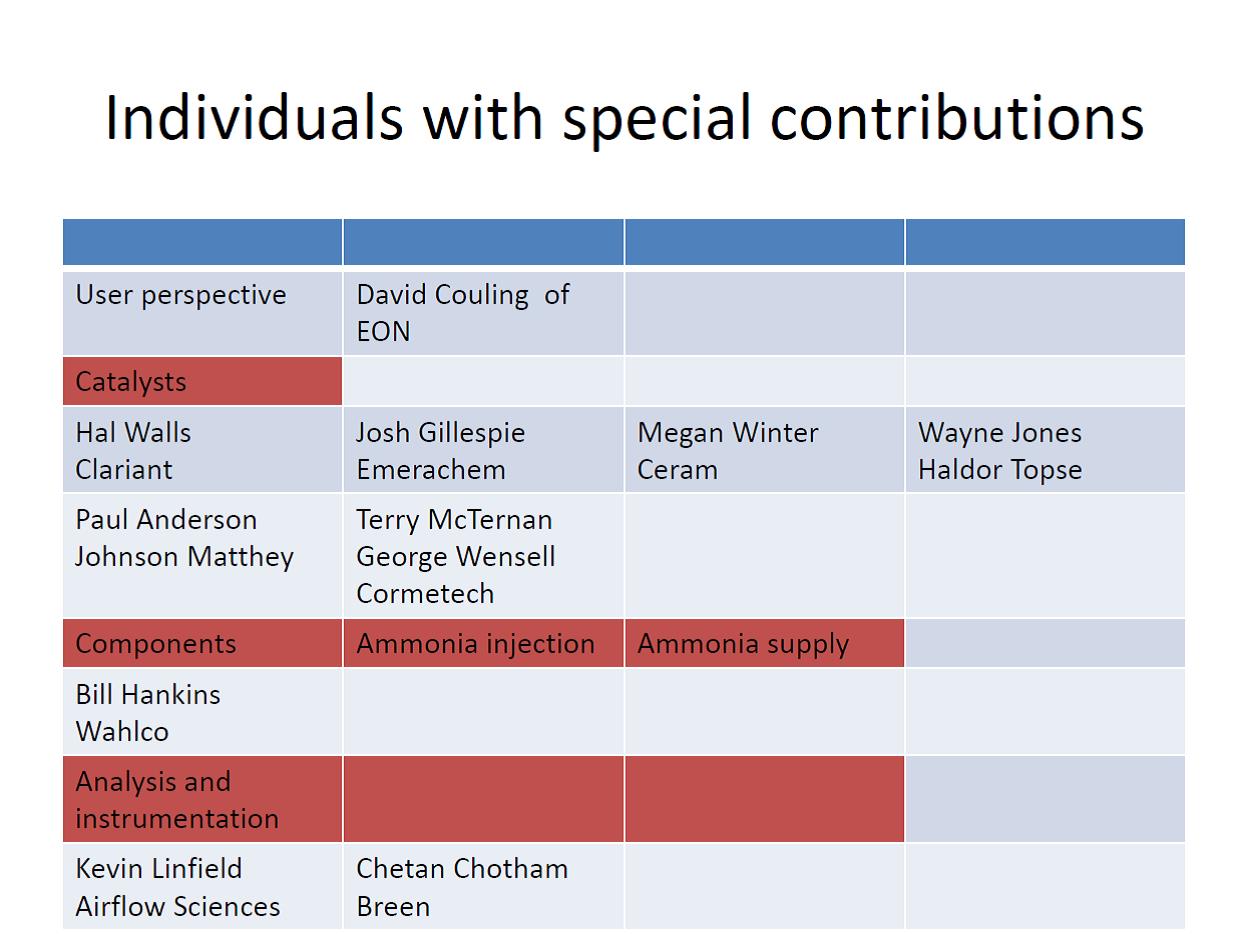

The Thursday 70 minute discussion of gas turbine (GT)

emission control and exhaust system options followed the new format. A slide

deck with 100 power points was the road map for the discussion with stops along

the way to cover new options. The road map displayed many options from noise

suppression to ammonia injection.

The stopping points were concentrated on catalysts,

testing, and ammonia injection. The

meeting started with David Couling

of E.ON.

His group of 1,000 engineers in the UK supports the power operations in

many countries. Presently many of the E.ON power plants are facing prospects of

EU regulations on combustion turbines with limits as low as 5 ppm. The problem

with meeting these regulations at the 15,000 to 20,000 MW of combustion turbine

systems which E.ON operates in the region is the tight space. So David was

interested in what the various suppliers would recommend to make the

installations more compact.

A number of catalyst, components and testing experts

provided details on the newest technology and how it may influence which option

to take.

§

Should you use high temperature catalyst or tempering air with a simple cycle

arrangement?

§

What catalyst configuration is best?

§

How different are the formulations between one catalyst supplier and another?

§

How do you deal with increased sulfur and other contaminants?

§

Can you combine CO and NOx conversion in one catalyst?

§

What is the best reagent choice? Anhydrous, aqueous or urea conversion to

ammonia?

§

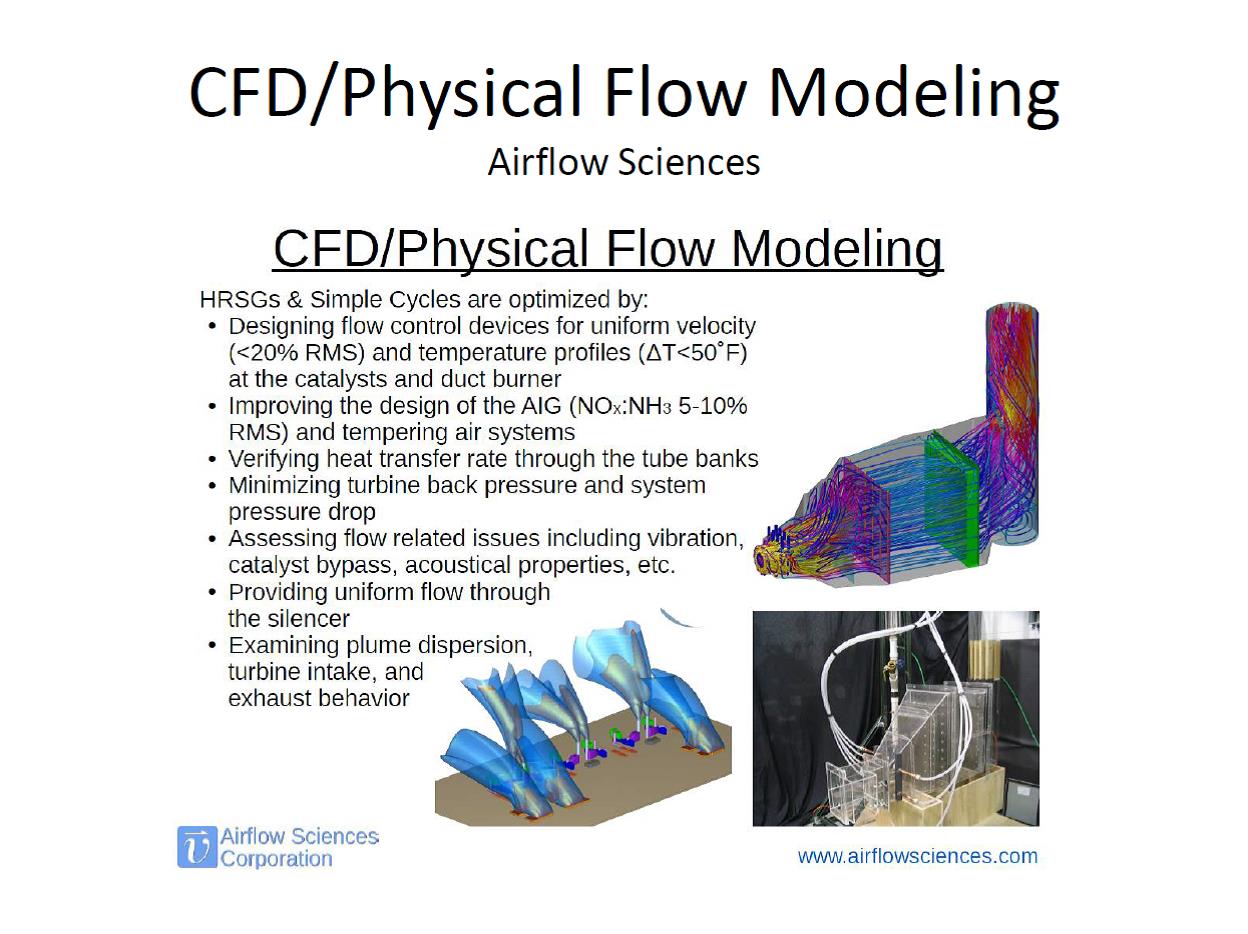

How important is CFD modeling ahead of final engineering?

A number of people weighed in on these issues.

Mitsubishi

has installed more than 600 SCR systems for gas turbines.

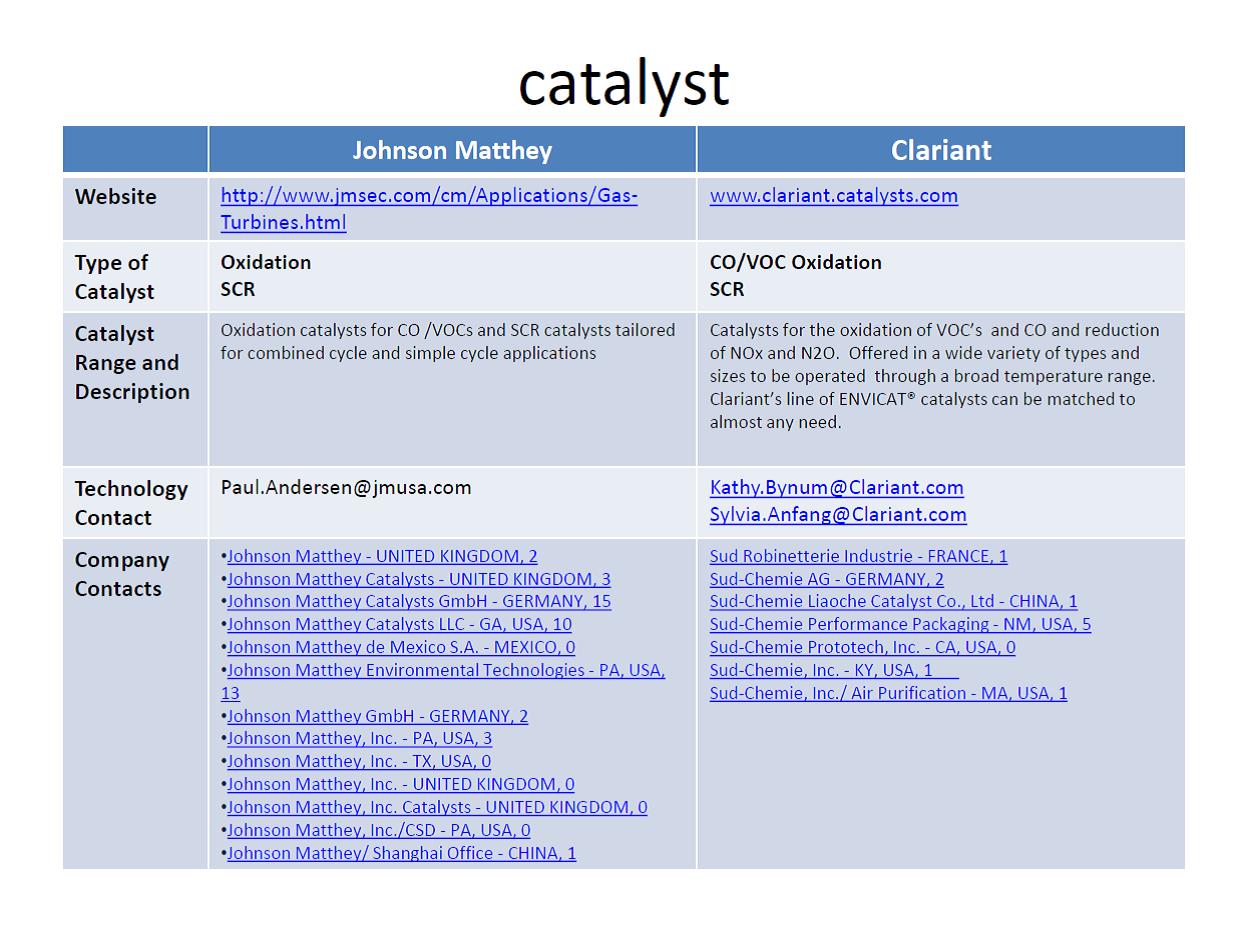

Catalyst

Johnson Matthey

uses a compact honeyocmb catalyst which will be attractive to those European GT

owners who must retrofit catalytic units into existing systems. Their oxidation

catalyst efficiency ranges from 90 to 95 percent depending on the the gas

temperature.

Clariant

makes the raw material and the catalyst. Their high temperature catalyst is

durable and efficient at temperatures in excess of 600°C.

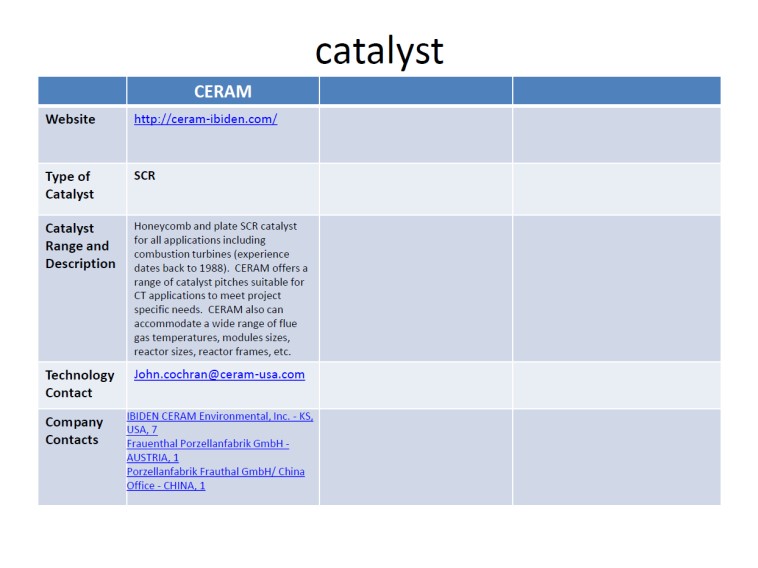

Ceram

can customize module size. This is an important feature for retrofit

applications in Europe where space is premium.

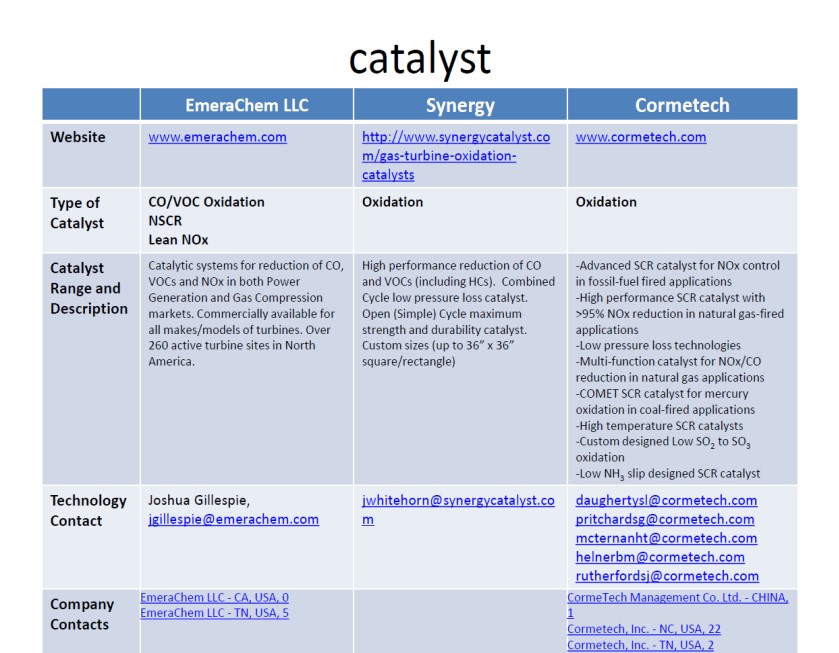

Cormetech

is a major supplier of gas turbine catalysts in the U.S., China and Europe.

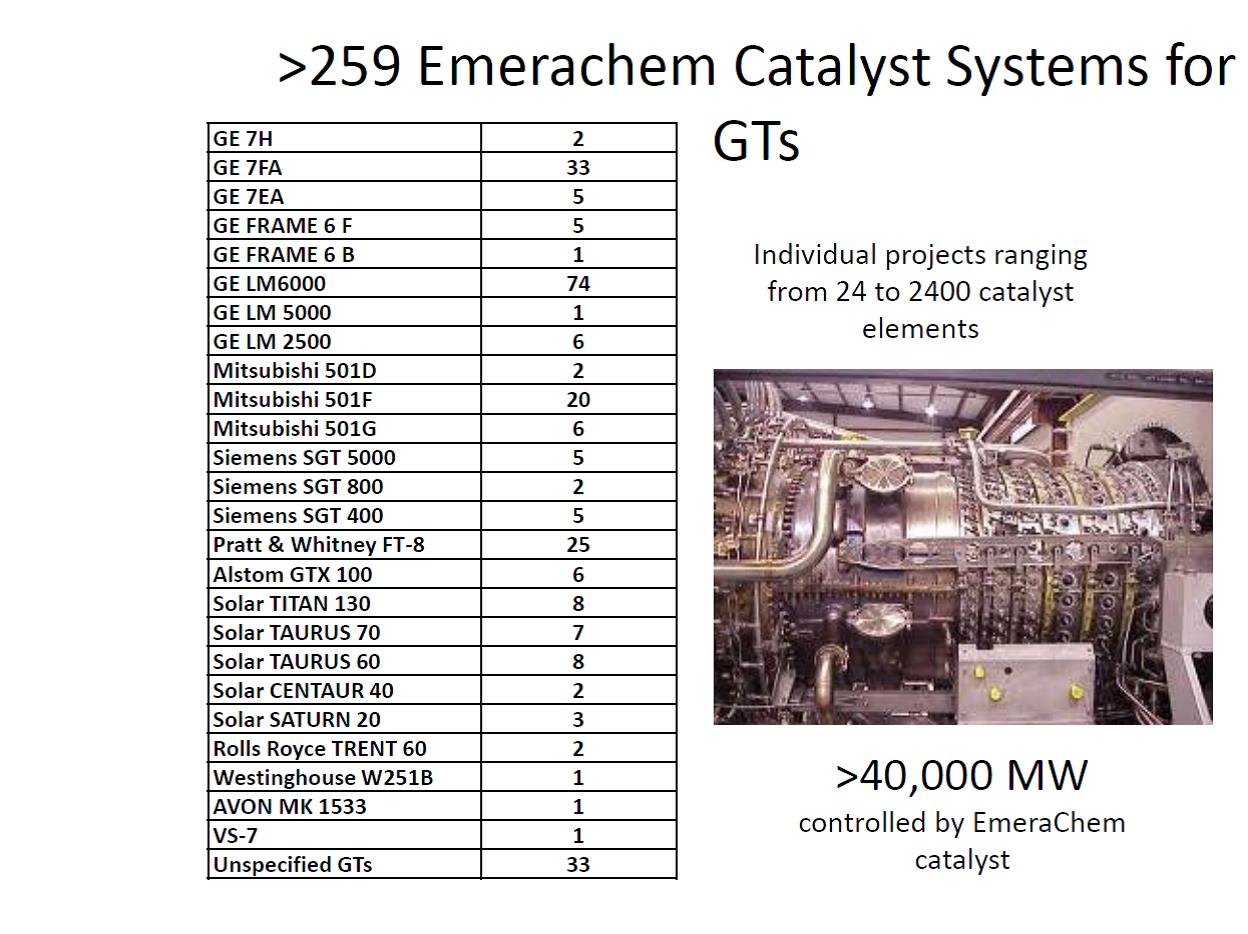

Emerachem

also has many installations.

Haldor Topsoe

has a combination NOx and CO catalyst.

§

GT series SCR catalyst impregnated with active precious metal.

§

Controlled concentration and placement of active metal reduces undesirable side

reactions.

§

Truly “Dual Function Catalyst” DeNOx and oxidation of CO and VOCs.

§

Catalyst is not poisoned by SO2.

§

Extremely low SO2 oxidation,

5 to 10 times less than traditional Pt-based catalyst, less fouling.

§

Very low oxidation of ammonia, conversion mostly to nitrogen and water under

800°F.

§

Dual function solution provides lowest possible pressure drop. Generally

one-half of traditional solution.

§

With placement of catalyst downstream of ammonia injection, liquid ammonia

injection can be used.

§

Up to 95 percent DeNOx and 95 percent CO oxidation with very low ammonia slip.

§

Ammonia consumption increases on applications above 650°F.

§

References stand at 34 units sold, 4 are operational including two MHI 501G CCGT

in Texas.

Mitsubishi is a major supplier of SCR systems for gas

turbines with more than 600 installations. The company has combined with Hitachi

and is now Mitsubishi Hitachi Power

Systems (MHPS). The former Hitachi is a major supplier of catalysts. So

the new merged entity is supplying both catalyst and systems.

Modeling and Testing

Modeling has lots of

benefits. Air Flow Sciences

is providing both the modeling and subsequent testing services for clients in

Europe and Asia as well as the U.S.

Breen

has developed an accurate way to determine SO3 at the HRSG.

Even though the levels are quite low the constant cycling creates

deposits on tubes. The net effect is to raise the flue gas concentration near

the tubes and therefore the acid dewpoint. The potential corrosion is of concern

and has sparked interest in the Breen analyzer.

Ammonia Injection

Wahlco

has been succcessful with their Ammonia on Demand or AOD process which provides

ways to convert urea to ammonia on site. There are two approaches, one for

smaller installations and one for larger ones.

The safety and availability of urea make it an attractive choice.

This

route map and summary is being posted in the gas turbine emission control and

exhaust system decision guide Gas Turbine Emission Control. This is a

protected site which is linked from the main website which is described in

59D Gas Turbine and Combined Cycle Decisions.

The

Decision system is organized to provide four knowledge needs: Alerts, Answers,

Analysis, and Advancement.

This

summary appears in the Gas Turbine Updates along with other new developments to

which users need to be alerted. Some of the more complete power point

presentations and papers submitted by the participants are being posted in the

database intelligence system to provide quick answers with the easy to use tier

system including subsidiary websites. The recording provides extensive analysis.

Future webinars will build on this one to provide additional analysis. The fact

that all the webinars are recorded makes it possible to work out very

comprehensive training (Advancement) programs.

The

entire August 6 recording can be heard at:

Gas Turbine Emission Control and Exhaust Systems

62 minutes

Hal Walls,

Clariant - Addendum

14 minutes

Speakers and participants in the Total Solutions Hot Topic

Hour on August 20 confirmed that customers want suppliers to offer a broader

scope of design and installation services. More operation and maintenance

support is also needed. Those companies offering a broad range of services

coupled with knowledge of the applications provide ways for the international

companies to eliminate local competition in developing countries.

An air polluter can buy components and design, operate and

service his pollution control system. Alternatively he can outsource all these

responsibilities. The revenue potential for all this outsourcing is defined as

the “Total Solutions Opportunity.”

The historical trend is toward greater and greater

outsourcing. The availability of new digital tools will accelerate this trend in

the future. This opportunity promises to deliver higher profits to suppliers and

lower life cycle costs and higher value products for operators. There are many

partial solutions as well as total solutions. Each needs to be evaluated.

McIlvaine stated that the reason operators need knowledge

and help is not because the experienced people are retiring but because

knowledge is growing exponentially and the human brain is not. A number of

the speakers offered other explanations. Leaner staffing by operators was one

explanation. Another was the perception that manufacturing jobs are not as

glamorous as software and electronics.

The need for broad-based

solutions is driven by a number of factors:

|

Factor |

Example |

|

Complex systems with

multiple control steps |

Coal-fired boilers, cement

kilns, chemical processes |

|

Valuable final product

recovery |

Precious metal mining |

|

Valuable process product

recovery |

Refinery catalyst, solvents

in chemical and surface treatment |

|

Difficult compliance with

air permit |

Many industries in many

countries where even start up and shut down

emissions are important. |

|

Safety |

Explosive gases |

|

Health |

Semiconductor toxic fumes |

|

Potential for air pollution

control system to negatively impact operations. |

Many industries |

|

Lack of skilled personnel

within the plant. |

Continuous trend |

|

Success of remote

monitoring |

Applicable to all

pollutants and operating parameters. |

|

Ability of suppliers to

provide a lower cost alternative. |

Reduction of repairs,

downtime, energy consumption, etc. |

The discussion involved a number of presenters and comments

from participants.

§

Clark

Griffith - Griffith Consulting,

has found success by providing all the customer needs from initial assessment to

installation and startup. Clark has an extensive background in thermal

oxidation. His services are available through the McIlvaine niche expert system.

§

Bruce

Galli - Marsulex, said

that the attractiveness of ammonium sulfate systems depends on the size of the

system e.g., more than 1.5 percent sulfur with flow equivalent to 200 MW to less

than 1,000 MW. The limitation on the high side is exceeding local demand

for ammonium sulfate.

§

Guisu Liu

- Mobotec, covered a range of

in furnace NOx and SOx reduction techniques.

§

John

Albritton - Paragon Air Heater,

explained the importance of air heaters relative to the size and performance of

downstream air pollution control equipment.

§

Martin

Schroter - Dürr, provided

details on the system using catalytic filters and powdered limestone injection

for cost-effective air pollution control and then heat and moisture recovery.

§

Rod

Gravely – Tri-Mer, also

discussed catalytic filters and the ability of his company to provide complete

turnkey systems. The system often competes with dry scrubbers followed by

conventional precipitators and SCR. Typically the Tri-Mer design is less costly

and takes 30 percent less space.

§

Tom Van

Remmen - Verantis, also

focused on complete turnkey systems. In some cases they are designing systems to

recover HCl and other valuable products. By offering a range of services they

have an international client base of companies such as BASF, Dow, and Eastman.

Tom says their business in China is down due to the lower level of activities of

international customers in the country.

§

Mike

Gregory - IAC, displayed

a new dry scrubbing system which uses a cyclone to minimize impact on a

downstream precipitator.

§

Craig

Thiry - Montrose, listed

a wide range of testing and consulting services available as a result of the

acquisition of 25 companies in recent years. Craig agreed that partnership with

turnkey system suppliers is a way to seamlessly provide what the customer needs.

§

Joe

Porcelli - Sulzer Chemtech,

described the static mixing technologies including the ammonia dispersion in the

flue gas stream.

The discussion was based on a series of power points

http://home.mcilvainecompany.com/images/Total_Solutions_8-21-2015.pdf

The full recording can be reviewed at:

Total Solutions

113 minutes

|

DATE |

UPCOMING HOT TOPIC HOUR |

UPCOMING MARKET UPDATES |

|

September 10, 2015 |

Power Plant Pumps |

|

|

September 11, 2015 |

Valve Market Forecast Changes |

|

|

September 24, 2015 |

Power Plant Water Monitoring

More information |

|

|

September 25, 2015 |

Pump Market Forecast Changes |

|

|

October 1, 2015 |

Power Plant Water Treatment Chemicals |

|

|

October 2, 2015 |

Fabric Filter Market Forecast Changes

|

|

|

October 22, 2015 |

Precipitator Improvements |

|

|

November 12, 2015 |

Dry Scrubbing |

|

|

December 3, 2015 |

NOx Reduction |

|

McIlvaine Company

Northfield, IL 60093-2743

Tel:

847-784-0012; Fax:

847-784-0061

E-mail:

editor@mcilvainecompany.com

Web site:

www.mcilvainecompany.com