Monitoring Newsletter

New product innovations have created considerable growth opportunities in the sensor market. The medical sensor market is the fastest growing end-use segment for chemical sensors and seems to hold the greatest potential for profit. Advances in the medical and diagnostic test market along with the increased use of chemical sensors for large-scale industrial and environmental projects have driven the market for chemical sensors. The demand for sensors will be fuelled by newer applications for established sensor products, including optical sensors, which are currently a hot product for generating revenue.

http://www.prweb.com/releases/chemical/sensors/prweb3609734.htm

Some of the most important environmental issues facing the cement industry includes greenhouse gas emissions and release of toxic chemicals. Global warming is of special interest due to the almost 1 ton of CO2 released every 1 ton of cement produced (5 percent of all global greenhouse emissions). The cement industry is attempting to upgrade plans with more effective flue-gas cleaning and monitoring equipment in order to reduce these emission levels. Products and systems of interest to the cement industry includes: ambient air quality analyzers, CEMS, particulate samplers, particulate monitors, and meteorological systems.

http://www.ecotech.com.au/applications/cement-industry

The average growth of the sensor market in Europe was estimated at 6% between 2007 and 2011, with the market worth 10 billion Euros in 2007 (28% of the World sensor market). Specifically, the French market is estimated at 15% of the European sensor market with a similar growth rate to that of the European market overall. The dynamics of the French market lie mostly in the demand for sensors within the aerospace and defense applications as well as the process and food industry. In comparison, the other main European sensor markets are Italy and Germany with dynamics in the automotive and industrial machinery instead. Looking at the European sensor market, the majority of the market lies in physical and mechanical sensor needs, representing 75% of the global market worldwide. The European market contains tremendous potential in the consumer, medical and environmental industries, relying on new sensor concepts such as smart, autonomous sensors. For example, this includes development in multi measurement and self-diagnostic sensors.

http://www.decision.eu/doc/presentations/sensor_survey_abstract.pdf

The majority of China's wastewater equipment industry consists of continuous and portable monitoring as well as large laboratory industries. However, the monitoring devices and equipment sector are underdeveloped in China, causing China to have to import the high-quality devices. The current supply of domestic monitoring devices is very limited but still commands a very high market share due to their low prices. China's environmental monitoring and analysis industry consists of the need for quality tests to be performed while water and wastewater treatment facilities operate (i.e. in-situ, continuous and online monitoring). Again, although these services are domestically available, their equipment and instruments are of much lower quality than that of more developed countries. To add to the domestic struggle for sensor and monitoring equipment development, most of the quality monitoring is done by state-owned monitoring stations that are authorized by the government that doesn't allow domestic companies to provide the monitoring services without government authorization. Never the less, this subsector is expected to grow due to the monitoring demands and proposals for co-supervision over monitoring stations along-side the government.

http://www.icwt.net/China%20Water.pdf

In the foreseeable future, it seems that the majority of demand for water analysis instrumentation will be derived from developing markets, especially India and China. These regions have seen tremendous growth over the past few years, resulting in a large increase in water monitoring product investments. This development has led to more widespread making of handheld and on-line monitoring systems for convenience, accuracy and reliability. Increased competition through all this development has aided product differentiation, price reduction, and technology enhancements. And although the online systems have the fastest growing market in the industry, the laboratory instruments still trump over the other markets with the largest product segment in the market.

http://www.prweb.com/releases/water_analysis/instruments/prweb8613281.htm

Water monitoring and testing companies cover a large range of applications including potable water, wastewater, swimming pool, beer and soda industries. Because of this, water must be monitored for various amounts of certain components depending on the industry. In response to this, the monitoring market is maturing to develop technologies for the testing of contaminants applicable across all the industries. There are also different types of monitoring, including integrated and discreet; causing product differentiation and an additional demand for data software to contain the collected information. The market of water monitoring services is dependent on a small number of large firms that dominate the market and it is currently very dependent on testing laboratories. However, there is still potential for new companies to make profit in this field since the global turnover for environmental sensing and monitoring products was recorded having a compound annual growth rate of 5.2%.

http://ec.europa.eu/environment/etv/pdf/ETV%20Final%20Report%20Business%20Case%20Annexes.pdp

Looking at the status of emerging sensor technologies dealing with VOC's in ground water, it is apparent that there have been many market changes to incorporate more effective ways of monitoring. The market has moved towards in-situ, commercialized automated, and handheld and field-portable systems for convenient water monitoring. There are many additional factors pushing the implementation of these new monitoring systems including having convincing reliability, achieving regulatory approval and being cost effective. Additionally, due to the millions of ground water samples collected and analyzed each year, there is a strong market to hold all these new technologies to make the monitoring industry worth investing in.

http://www.clu-in.org/download/char/542r03007.pdf

Pentel explains that there are many opportunities currently available and to come in the water monitoring market. The number of monitoring systems required by industrial companies (due to EPA regulations), the military and the municipal water providers into their reservoirs, rivers and distribution systems leaves a possibility of an extremely large pool of prospective customers for these monitoring companies. The water-quality testing market is getting so large that it is projected alone to be a billion-dollar market just in the U.S. by 2014.

http://www.petrelbiosensors.com/pdfs/PetrelBackgrounder.pdf

It is suspected that the government expenditure on water monitoring equipment in China will grow drastically in the coming years. The MEP of China has already spent 42% more on environmental monitoring and information management between 2010 and 2011. Although the demand for monitoring equipment in China isn't developing quite as fast as expected due to "patchy implementation of regulations," there still are legal requirements that large polluting enterprises must install and operate monitoring instruments, which hints that the market is not going to decrease any time soon. In addition, only 60% of all water monitoring instruments are domestically created, also signaling huge potential in the local market.

http://www.globalwaterintel.com/archive/12/6/general/keeping-close-watch-monitoring-markets.html

The U.S. has great potential in benefiting greatly from China's necessity for water monitoring products. The market is already large and expanding rapidly due to issued laws with increasing severity of punishments. Most of the parameters that need monitoring in China are already covered by many U.S. designed water monitoring products. Specifically, the market in China for water monitoring system lies in water quality improvement, which has already started with the continuing online emissions monitoring equipment (CEM), an important part of China's plan to create an integrated water monitoring network. The Ministry of Environmental Protection (MEP) has also been active in the micro-managing of monitoring systems in China, beginning with the 11th Five Year Plan to reduce a major pollutant, COD, by 10%. However, many other countries are starting to see the potential in this market that the U.S. has keyed into. Foreign as well as domestic suppliers have begun to see the likely profit in selling monitoring products to China, helping the market gain momentum. In order to keep up the profits in the coming decades, the U.S. will need to continue their high level of quality while finding ways of decreasing the cost.

http://egs.apec.org/uploads/docs/China_WaterMonitoringTechnology.pdf

A market study was conducted for FECC on China’s air quality monitoring, mitigation and environmental health in order to establish overall view on China’s ambient air emission monitoring and improvement market. The goal was to find market areas with greatest potential for business cooperation between China and Finland in conjunction with market study previously done on Municipal Solid Waste Management and Wastewater Management. A current status of the air quality monitoring in different regions of China was evaluated based on pollutant. In the Air pollution emission monitoring market, the main equipment employed is Continuous Emission Monitoring System (CEMS). Large scale industries, especially power plants, are required to install CEM equipment to measure emission concentrations of SO2, NOx, PM and other parameters. Production value of CEMS reached RMB 1.61 Billion in 2008 with average rate of increase being 50.44% from 2000-2008. Market size of air pollution monitoring equipment is forecasted to reach RMB 12.455 billion by 2013 and RMB 19.529 billion by 2015.

This report presents the Data Acquisition and Handling Systems (DAHS), analyzer types, sample acquisition methods, and CEMS manufacturers for all EDRs submitted in 2012. It presents the market share represented by the various manufacturers of the DAHS, SO2, NOx, CO2, O2, and opacity monitoring equipment. The data generally show only moderate changes since 2008, with the manufacturers who had the “lion’s share” of the market typically retaining that position. Thermo Environmental has provided the majority of the SO2 and NOX analyzers used under Part 75 (about 72% and 62%, respectively). In addition, California Analytical and Thermo Environmental represent over 72% of the CO2 analyzer market combined.

http://www.rmb-consulting.com/papers/CEMS%20Equipment-2012.pdf

The cement industry is a large purchaser of process gas and stack gas monitoring equipment. The world market for 2012 was forecast at $ 1100 million including support services but it has now been downgraded to $ 700 million due to a slippage in the air toxic rule issued by EPA. Compliance was to have been in 2013 and is now 2015. Purchases of mass particulate, mercury, and HCl monitors have therefore been delayed. Most would have been purchased in the next 6 months. The total market for fluid/gas treatment and control has been downgraded by McIlvaine Company from $ 10.5 billion to $ 8.4 billion this year. The monitoring products and services being affected include mercury CEMS, process gas analyzers, laboratory equipment used by stack testing and water testing services, flow, level, and contaminant instrumentation in the scrubber recirculating and wastewater, bulk material flow monitoring for dry lime, activated carbon and other reagents. The suppliers of protocol gases are also negatively impacted.

Semiconductor manufacturers will spend $2.3 billion in 2012 for flow control and treatment products. This includes products used to extract water from sources, purify it for use in chip washing and other purposes and to purify effluent prior to discharge. The water used in semiconductor processing needs to be extremely pure. Water from a river or even water already processed in a municipal drinking water plant must be subjected to a series of steps which often include granular media filters, cartridges, reverse osmosis, ion exchange and degasification. The water must be carefully monitored for a number of parameters. The semiconductor industry is growing at rates faster than GDP thanks in part to photovoltaic production as well as mobile communications in which Asia is the largest producer and its lead is forecast to grow. China is gaining on Korea, Taiwan and Japan as a major producer.

Revenues for pumps, valves, treatment equipment, chemicals and monitoring for municipal water and wastewater plants around the world will exceed $52 billion in 2012. The biggest investment will be $21 billion for flow control. The smaller $9 billion separations segment will grow at a faster rate than the flow control. The $2 billion water monitoring market will grow at close to double-digit rates over the next five years as municipal plants switch from labor intensive manual testing to continuous monitoring. Another driver is the lower consumption of chemicals and increased energy efficiency.

Pump and valve purchases in 2012 by power plants, municipalities and industry will be $90 billion. The biggest purchasers in the power industry will be investors in coal-fired power plants. Most of these power plants are being built in Asia. Combined cycle gas turbine construction will account for a relatively small portion of the power total. The nuclear industry represents an even smaller segment. A sizable portion of the investment in a new hydropower plant is for flow control but only a few large hydro plants will be built in 2012. Municipal wastewater treatment plants use more pumps and valves in the treatment process than drinking water plants but the amount of water moved from and to the plants is roughly equal. Water reuse is becoming much more popular recently. This expands the market for treatment and, in some cases, also increases the transport requirements. Asia is the largest purchaser and will continue to gain over the other regions in the next five years.

The market for air pollution control equipment and consumables will be $35 billion in 2012 according to a McIlvaine company recorded presentation and discussion on May 31, 2012. More than half of the power plant purchases will be in Asia. The fabric filter segment will grow at a faster rate than the other segments over the next decade. Within this segment the sales of membrane media will grow faster than other options. The precipitator segment will grow at the lowest rate. Industrial plants in the U.S. will be spending over $1 billion/yr over each of the next four years to comply with toxic air pollution control standards for their boilers, kilns and incinerators. The biggest investments will be in fabric filters and continuous emissions monitors.

The markets for air and water pollution control and monitoring are expanding slightly and remain substantial despite the financial problems of the European region. The 2012 revenues will reach $6.4 billion. Russia, former Soviet bloc countries, Eastern and Western Europe are all included. The financial crisis in the EU is having some negative impact. This could be further exacerbated if countries hoping to gain EU status through installation of pollution control measures lose interest in joining.

Analyzers to measure constituents in various gases and fluids are each designed for specific chemicals or physical properties. Since there are hundreds of different chemicals and many physical properties, there are many unique instrument designs. There are more than 5,000 suppliers of instruments to measure gases and fluids worldwide. There are 3,000 instrument makers in China alone. Given the language inconsistencies, it is a real challenge to determine which of these companies make an instrument which fits the specific needed criteria. The McIlvaine Company (www.mcilvainecompany.com) is developing a decisive classification system in Chinese, English and other languages will allow monitor purchasers in developing countries to efficiently utilize the world’s existing knowledge. The system identifies monitoring products by application (there is a big difference between shale oil and oil shale), function (analyzer, sample system, etc.) medium (ambient air, stack gas), properties measured, (ammonia, arsenic), measurement parameters (ppb, ppm, count) operating principle (optical, electrochemical) and mode of use (handheld, portable, etc.).

Power generators will spend $390 billion in 2013 for new coal-fired boilers. Direct costs of equipment will be $260 billion while indirect costs will be $130 billion. There will be a mix of subcritical, supercritical and ultra supercritical boilers. Most of the units which will be installed will utilize wet cooling. However, some units in China and elsewhere will install dry cooling systems. These add as much as 5 percent to the total plant investment. On the other hand, the cost of the Chinese plants will be only 60 percent of the cost for the same plant in the U.S. or Europe. All new plants will have high efficiency particulate control (electrostatic precipitators or fabric filters). Most of the new plants will use extensive wastewater treatment and some water recovery. The investment in new coal-fired power plants in 2013 will exceed the investment in gas turbines and nuclear plants combined.

To Steve Maxwell, there are four critical underlying and recurring themes that may resolve our pressing water problems. One is to balance our resource trade-offs. Maxwell states that it essential to find the best minimization of, in this case, our water and carbon footprints. Essentially, the question lies, what is a unit of water worth versus a unit of energy versus an avoided bit of carbon into the atmosphere? Secondly, Maxwell pushes to think about water consumption in terms of virtual water, the total amount of water that is required to produce the goods and services we buy or that is required by the behaviors in which we engage. With this, the efficiency of water consumption where it is the scarcest must be evaluated. Thirdly, Maxwell suggests it is necessary to develop holistic approaches to water. Rather than seeing water in separate categories, such as groundwater, drinking water, and wastewater, we need to see that these waters are interconnected and can all affect energy supply, air pollution and urban development. Therefore, water policies should be consistent to help treat all water industries as possible reusable water locations. Lastly, Maxwell states we must prepare for the rise of water prices. Water is significantly underpriced, leaving no economic incentive to conserve it or use it wisely. Once water is priced accurately, there will be a greater reliance on water re-use, recovery, monitoring and analyzing to manage it more efficiently.

http://www.summitglobal.com/documents/Maxwell2012WaterMarketReview-a030912.pdf

ABB is a current leader in the energy and automation technology. Relative to water monitoring, ABB produces many specific sensors that monitor anything from elemental content to turbidity and flow in water. Their expansive list of measurement products allows for several industries to benefit from them, including the cement, mining, water and wastewater industries. Here is Gerhard Brandt discussing the products for the power industry at the ABB Stand at Power-Gen Europe.

http://www.mcilvainecompany.com/PowerGenEurope2012/PowerGen_Europe_2012_ABB_AG.htm

At Power-Gen Europe, BFI Automation highlighted their wide range of fail-safe flame monitoring systems and bus compatible compact flame controllers for multi burner and fuel applications. BFI Automation also has temperature measurement systems that showcase the company’s recent innovations. Highlighted in their Power-Gen presentation was their newest Flame Scanner which is self monitoring and suitable for continuous operation. It can monitor light and heavy oils, and natural, furnace and Claus gas. Here is Eberhard Rollecke with the system on display at the BFI Automation stand.

http://www.mcilvainecompany.com/PowerGenEurope2012/PowerGen_Europe_2012_BFI_Automation.htm

Conax Technologies is a supplier of temperature sensors to the power generation industry. Conax aims and creating improved sensors for gas and steam turbines. One sensor shown at Power-Gen 2012 was an air inlet or oil temperature sensor. This product is manufactured from insulation material of the highest purity, yielding excellent insulation resistance and sensor repeatability. Bearing sensors were also highlighted at the exhibit, including a sensor intended for embedded applications where temperature monitoring is critical for a machines performance and reliability. Richard Lyon is shown here at the Conax stand, talking about sensors and other supplies Conax has to offer.

http://www.mcilvainecompany.com/PowerGenEurope2012/PowerGen_Europe_2012_Conax_Power_GGeneratio.htm

Durag manufactures and develops products for environmental monitoring, including products such as flame monitoring, burner controls, process and ambient monitoring, and environmental data management systems. Specifically at Power-Gen, Durag focused on some products, such as the HM 1400 Mercury analyzer for exhaust gas. They also presented an environmental and process data acquisition system that has multiple standard inputs of any analyzers or sensors. Durag also showed their flame monitors. Roland Zepeck, Melanie Mertens and Jurgen Kaizek talk on behalf of Durag at Power-Gen Europe.

http://www.mcilvainecompany.com/PowerGenEurope2012/PowerGen_Europe_2012_DURAG.htm

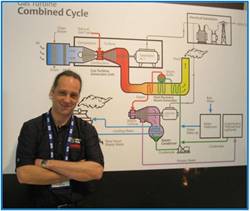

Emerson Process Management is a leader in helping gas turbine combined cycle plants to meet their production needs. Emerson's product line ranges from instrumentation, control, and automation technologies. These include analytical devices, valves and final control elements, systems and software. Pat Galik is shown here with a presentation of Emerson’s new Combined Cycle Process.

Endress + Hauser offers instruments, services and solutions in the Power & Energy industry. At Power-Gen, Endress + Hauser showcased their Promass, a flow meter with excellent accuracy, more process information and no installation problems. The Promass can be used on either gases or liquids and can also measure temperature, volume, density and viscosity. Endress + Hauser also showed off some of their thermometers and pressure and level sensors that can work in many industries and conditions. Two of Endress + Hauser employees, Ravi Jethra and Reinhard Salzmann are shown with the new Promass X.

http://www.mcilvainecompany.com/PowerGenEurope2012/PowerGen_Europe_2012_Endress_+_Hauser.htm

KRAL serves many different industries with their variety of products, including fuel consumption measurement instruments. Apparent at Power-Gen by the KRAL Volumeter and OMG Series Flowmeters, KRAL has many high-precision volumeters and flowmeters that have high accuracy, are robust, and can follow any rapid fluctuations in the flow caused by pulsations. Also shown at the conference was a fuel consumption measurement system that can handle pressure pulsations and temperature differences, the KRAL Fuel Consumption Measurement System. Andreas Langle and Richard Leopold highlight KRAL’s screw pumps at Power-Gen Europe.

http://www.mcilvainecompany.com/PowerGenEurope2012/PowerGen_Europe_2012_KRAL.htm

Testo AG is one of the leading manufacturers of portable and stationary measurement technology worldwide. Featured at this year’s Power-Gen was a new generation flue gas analyzer for industrial applications, named the Testo 350. The new Testo 350 is an analyzer with up to six sensors (O2, CO, NO, NO2, SO2, CO2, H2S and HC), a new graphic color display and a completely new designed housing. The Testo 350 is used for commissioning, maintenance and operative measurements on industrial burners, industrial engines, gas turbines or flue gas scrubber systems, as well as in the measurement of the gas atmosphere in a furnace room or in kilns. In addition, Testo's Testo 350-MARITIME was shown, featuring a gas sampling probe with probe pre-filter and special hose for NO2-/-SO2 measurements and a robust protective case for measurements on ships according to MARPOL 73/78 and NOx Technical Code. Here is Raphael Rotter and Michael Willmann presenting Testo’s products at this year’s Power-Gen Europe.

http://www.mcilvainecompany.com/PowerGenEurope2012/PowerGen_Europe_2012_Testo.htm

Thermo Instruments is measuring mercury from the beginning to the end of the cement process. The mercury in the raw limestone is measured with X-ray spectrometry. The stack gas mercury is measured by the Thermo mercury CEM system. Cement plants are forced to use the limestone in the vicinity of the plant as a raw material. Transportation costs are too high to consider imports from other areas. The amount of mercury in the limestone varies greatly from one locality to another. When the limestone is heated virtually, all the mercury is vaporized and would exit in the stack except for capture in the air pollution control equipment. At the ACHEMA show in Frankfurt, Germany last week, we learned about the extensive use of Thermo XRF spectrometers in cement plants. Here is the unit on display with the characteristics of the instrument explained by Franz Mollekopf.

http://www.mcilvainecompany.com/Decision_Tree/Achema Thermo 2012.htm

At the Powder and Bulk Solids Show in May we learned from Tim Cokeley about the extensive line of Thermo Bulk weighing and monitoring products including conveyor belt scales, weigh belt feeders, tramp metal detectors, coal and mineral sampling systems, level indicators, conveyor safety switches and a variety of other specialty process control instruments. All products are ISO 9001 certified. Tim Cockeley kneels next to a Thermo Fisher product shown at Powder & Bulk 2012.

http://www.mcilvainecompany.com/Decision_Tree/Powder & Bulk 2012 THermo.htm

The new European Water Framework Directive is a structured program for management of water resources in order to achieve overall good quality of water by 2015. This will be accomplished through careful monitoring of surface water and groundwater and implementation of gradual improvements. Specifically, the WARMER project was launched in 2006, aiming to create an extended system for real-time water quality monitoring to help achieve the end goal. To do this, the project integrates chemical sensors, analytical chemistry, remote sensing and extensive networking of environmental water monitoring data in space and time. By 2015, they are hoping for improved interactive functions for near real time calibration of remote sensing images using point measurement data collected by an automated water monitoring station in order to develop spatial and short term temporal forecast of pollution coming from accidental spills in natural water bodies.

http://www.zetaced.com/projectwarmer/components/com_joomlaboard/uploaded/files/Gunatilaka_et_al.ppd

Singapore start-up Membrane Instruments and Technology (MINT) has released a system that combines three monitoring processes into a single system. It pinpoints the exact location of contamination and reduces laboratory hassle. It has a MEM-Shield that can pinpoint with accuracy any faults in the water plant filters without having to bring the section of the water plants offline. Once a problem with the water quality is detected, the sensor switches to a more sensitive mode. According to MINT, S$200,000 a year can be saved by using this new system and 2 companies are already giving the new technology a try. Plans are in place to start trialing the technology in the US by the end of the year.

The town of Walden lies 20 miles from the Wyoming border in Colorado near Steamboat Springs. Their water treatment plant now has a requirement to measure finished water because their original pump station design did not include a flow meter. The waste treatment plant also has limited space and a need for high accuracy flow measurement system which makes the installation of a flow meter difficult. And, of course, the local government intends to minimize both instillation and maintenance costs. Technology has led McCrometer to create a system that evaluates multiple flow measurement options suited for municipal water systems. It has high accuracy, flexible installation requirements and versatile capabilities with a design that includes a self-conditioning cone within the meter. This new invention was ideal for the town’s water plant, creating an additional bonus of having the ability to measure finished water effluent as well. A SCADA system program has been programmed along with the flow meters for easy online readings.

Whitewater Technology Group has introduced to the US market a monitoring system that uses non-pathogenic luminous marine bacteria as an early sensor. It provides real-time, online monitoring and can easily expand by just adding more monitoring units. This technology has already been verified by the EPA's ETV program. The bacteria works by when the water is contaminated, the bacterium reacts by reducing the amount of emitted light which generates an automated contamination alert. The biggest positive to this technology is that the bacteria responds directly and instantly to a wide range of dangerous contaminants. However, the system doesn't give specific information about the contaminant.

Many potential polluters of China's rivers and lakes have not been meeting government requirements to monitor their water quality. Although China's government policy since 2005 states that all large polluters must have water quality monitoring stations, many companies have not been adhering to the policy. There seems very little reason that these companies should not been adhering to these policies due to the recent developments in technology that allow for automated water monitoring rather than necessary lab analysis. So why are companies disobeying the laws? Many companies fear the production of unfavorable data. Companies are currently required to submit data four times a day to environmental protection agencies but companies can easily adjust their waste emission time to avoid the possible 'bad' data. The penalties for breaking the rules are also not severe; the fines being far lower than the cost of sewage processing in the case of pollution. This seems ridiculous upon seeing that there have been 140 major water pollution cases since 2005. The solution is seen by the agencies working closely to share their data frequently: "Even if polluters do hide data, their emissions will influence the water quality in nearby rivers which are regularly monitored by the Water Resource Ministry. The ministry could forward pollution data to environmental protection agencies, which could soon discover which polluters are making emissions or falsifying data," says Qiu Tongyu, commercial manager for Hach. Hopefully for China's residents, the public demand for knowledge will pressure polluters to use these new automated monitoring devices and the environmental agencies will punish the wrongdoers.

http://www.rsc.org/chemistryworld/News/2008/August/26080802.asp

Danaher's presentation towards investors highlights parts of their growth in the water quality industry. They have extended their market with a 20% growth after developing a new Spectrophotometer DR3900 and have become the first company to market a field instrument for hydraulic fracturing, a $10 M + market opportunity. They have also shifted some focus to designing products in China for China to address local Chinese methods and unique regulations (since local products currently contribute to >20% of revenue). As far as water quality in the emerging markets go, Danaher had experienced a +25% revenue between 2006 and 2011 and, just in 2010, a +$100 M revenue in China. Looking forward, Danaher sets sights on continuing their investments in emerging markets, adding on Brazil, Russia and India to their list.

http://phx.corporate-ir.net/phoenix.zhtml?c=82105&p=irol-presentations

Modern Water has now acquired Cogent Environmental, a company dealing with detection of heavy metals in water and wastewater streams. Together they will create a new monitoring division, aiming on continuous monitoring rather than sampling. “There’s a push towards increasing levels of monitoring and increasing environmental awareness,” said Modern Water CEO Simon Humphrey. “In addition, the market’s moving towards continuous monitoring, rather than spot sampling,” he told GWI.

http://www.globalwaterintel.com/news/2011/5/modern-waters-measured-approach-water-monitoring.html

The challenges of maintaining a continuous emissions monitoring system (CEMS) just got a little easier. In today’s utility plant environment, with more limited resources and continually increasing emissions monitoring burden, CEMS technicians now have an additional “tool” to facilitate CEMS operation and maintenance (O&M) efforts. At previous EPRI CEM User Group Conferences, a few presentations have discussed the concept of automating CEMS to reduce manual recordkeeping efforts and improve diagnostic capabilities. This new “tool” pushes the concept of automation one step further. This solution is exemplified at Kansas City's Hawthorn Generating Station where hardware and software were developed that allows the CEMS technicians to more efficiently operate and maintain the CEMS.

http://www.rmb-consulting.com/papers/Technicians%20Assistant.pdf

Xylem Inc. announced that it has acquired MJK Automation A/S, a privately owned company headquartered in Naerum, Denmark for approximately $12.3 million (DKK 75 million). With operations in Denmark, Norway, the Netherlands, the United States and Singapore, MJK is a leading manufacturer of flow and level sensors, and measurement and control technology for water and wastewater applications. MJK generated revenue of approximately $10.7 million (DKK 65 million) for the fiscal year ended June 30, 2012. MJK products are used in water, wastewater, environmental and irrigation applications where critical measurements are required in pipes, wells, open channels and canals. Sensor technologies include ultrasonic, hydrostatic and electromagnetic plus Remote Telemetry Units (RTUs) for monitoring and control units ideally suited for field, online and lift station applications.

http://investors.xyleminc.com/phoenix.zhtml?c=247373&p=irol-newsArticle&ID=1714632&highlight=

On June 5th, EPA and plaintiffs in the case American Lung Association v. EPA reached a tentative settlement agreement under which the agency agreed to sign the final revised particulate matter (PM) National Ambient Air Quality Standard (NAAQS) by December 14, 2012. EPA also asked the court to allow the agency until June 14, 2012 to sign a proposed rule and to postpone a June 11 hearing to determine a timeline for signing the final revised NAAQS. The case was filed by the American Lung Association and National Parks Conservation Association, along with the states of New York, California, Connecticut, Delaware, Maryland, Massachusetts, Oregon, Rhode Island, Vermont and Washington, to compel EPA to issue the revised NAAQS. The tentative settlement agreement calls for parities to draft a proposed consent decree by June 15, 2012.

Scientists at Trinity College Dublin found that exposure to nanoparticles can have a serious impact on health, linking it to rheumatoid arthritis and the development of other serious autoimmune diseases. Environmental pollution including carbon particles emitted by car exhaust, smoking and long-term inhalation of dust of various origins have been recognized as risk factors causing chronic inflammation of the lungs.

The U.S. Environmental Protection Agency (EPA) and the U.S. Dept. of Justice announced that Hess Corp. has agreed to pay an $850,000 civil penalty and spend more than $45 million in new pollution controls to resolve Clean Air Act violations at its Port Reading, NJ, refinery. Once fully implemented, the controls required by the settlement are estimated to reduce emissions of nitrogen oxide (NOx) by 181 tons per year and result in additional reductions of volatile organic compounds (VOCs). High concentrations of NOx and VOCs, key pollutants emitted from refineries, can have adverse impacts on human health, including contributing to childhood asthma, and are significant contributors to smog.

http://www.mcilvainecompany.com/Decision_Tree/Hess Corp Monitoring Newsletter July 2012.htm

The Port of Los Angeles became the first seaport in North America and the Pacific Rim to adopt an international clean air program that rewards ocean carriers for bringing their newest and cleanest vessels to the Port. The Los Angeles Board of Harbor Commissioners formally approved an Environmental Ship Index (ESI) program to take effect July 1.The ESI is a web-based tool developed by the World Ports Climate Initiative (WPCI), a project of the International Association of Ports and Harbors (IAPH). The ESI program, already underway at several major European ports, offers immediate and significant clean air benefits by rewarding vessel operators for voluntary engine, fuel and technology enhancements that reduce emissions from ships beyond the regulatory environmental standards set by the International Maritime Organization (IMO). Ship emissions are the single-largest source of air pollution from port-related operations.