Coronavirus Technology Solutions

August 7, 2020

Evaluating Co-benefits of Masks and Filters for

COVID and Other Contaminants

Verdex Nanofibers have Advantages in Masks and

Air Filters

Hifyber Nanofiber Masks Combine High Efficiency

and Comfort

Fibertex Nonwovens has Nanofiber Products for

Both Face Masks and HVAC Filters

Clean Recirculating Air Not Sanitation Should be

the Top Priority for Schools

___________________________________________________________________________

Evaluating Co-benefits of Masks and Filters for COVID and Other Contaminants

It is hard to visualize that we inhale and exhale millions of particles every minute. It seems impossible to comprehend how our lungs can function given this particle barrage. It starts to come into perspective when you learn that the weight of particles you inhale are very minimal where ambient particle levels meet the WHO limits. Nevertheless since COVID is also tiny the numbers of small particles become meaningful.

The air pollution industry relies on weight to

measure pollution. In fact a HEPA filter is used

to measure air pollution efficiency. If zero

weight of particles is caught in the HEPA filter

then the assumption is that the pollution is

zero. The cleanroom industry doesn’t concern

itself with weight. If there is enough weight to

measure it is a very unclean room. In fact the

efficiency of HEPA filters is determined by

particle count. So the message from the

cleanroom to the air pollution industry is that

the absolute filter is not absolute.

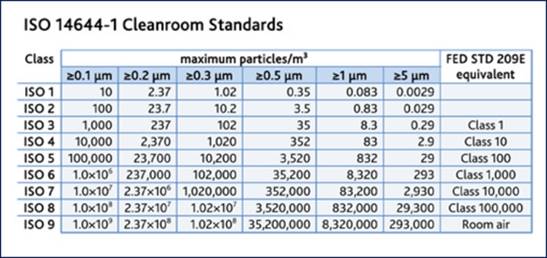

COVID attaches to particles. Also one way to evaluate COVID reduction is to measure the particles in the air before and after filtration. Pharmaceutical cleanrooms rely on the particle measurements as a surrogate for virus and other microbial contaminants. A class 100 cleanroom reduces the number of 0.5 microns down to 3500/m3 or 100 per ft2. By contrast room air has more than 35 million 0.5 micron and larger particles per cubic meter. So there is a10,000 time reduction. A Class 1 cleanroom which would be used for vaccine filling would reduce particulate to just 35 particles 0.5 microns and larger.

The prevailing efforts in selection of masks and filters only reduce 0.5 micron particles to somewhere still in the millions/m3.

More insights are needed relative to the very

large number of particles in the atmosphere and

therefore inhaled along with the virus.

In our July 27 Alert we analyzed room air.

The average individual in a room of average air

purity will breath in and exhale many millions

of particles every minute. Here are the

particles by size in each breath.

|

Particles in Room Air and in Breath |

|||

|

Particle diameter greater than or equal in micrometers |

Number of particles per cubic meter |

Particles per breath -Tidal volume- |

Particles per minute exhaled based on |

|

0.1 |

1,000,000,000 |

500,000 |

7,500,000 |

|

0.2 |

237,000,000 |

118,000 |

1,770,000 |

|

O.3 |

100,020,000 |

50,010 |

750,150 |

|

0.5 |

35,000,000 |

17,500 |

262,500 |

|

1 |

8,320,000 |

4160 |

62,400 |

|

5 |

293,000 |

147 |

2205 |

We have thought to extrapolate these numbers for

an individual location based on the air quality

measured in mg/m3.

But we find out that just because Delhi

has 23 times the WHO ambient PM 2.5 limits

deemed you cannot predict that a person will

breath in and out 23 times as many ultra-fine

particles.

A

recent study addressed the question “Can

mitigating only particle mass, as the existing

air quality measures do, ultimately lead to

reduction in ultrafine particles (UFP)? The aim

of this study was to provide a broader urban

perspective on the relationship between UFP,

measured in terms of particle number

concentration (PNC) and PM2.5 (mass

concentration of particles with aerodynamic

diameter < 2.5 μm) and factors that influence

their concentrations. Hourly average PNC and PM2.5 were

acquired from ten cities located in North

America, Europe, Asia, and Australia over a

12-month period. A pairwise comparison of the

mean difference and the

Kolmogorov-Smirnov

test with the application of bootstrapping were

performed for each city. Diurnal and seasonal

trends were obtained using a generalized

additive model (GAM). The particle number to

mass concentration ratios and the Pearson's

correlation coefficient were calculated to

elucidate the nature of the relationship between

these two metrics.

Results show that the annual mean concentrations

ranged from 8.0 × 103 to 19.5 × 103 particles·cm−3 and

from 7.0 to 65.8 μg·m−3 for PNC and

PM2.5, respectively, with the data

distributions generally skewed to the right, and

with a wider spread for PNC. PNC showed a more

distinct diurnal trend compared with PM2.5,

attributed to the high contributions of UFP from

vehicular emissions to PNC. The variation in

both PNC and PM2.5 due to seasonality

is linked to the cities' geographical location

and features.

Clustering the cities based on annual median

concentrations of both PNC and PM2.5 demonstrated

that a high PNC level does not lead to a high PM2.5,

and vice versa. The particle number-to-mass

ratio (in units of 109 particles·μg−1)

ranged from 0.14 to 2.2, >1 for roadside sites

and <1 for urban background sites with lower

values for more polluted cities. The Pearson's r ranged

from 0.09 to 0.64 for the log-transformed data,

indicating generally poor linear correlation

between PNC and PM2.5. Therefore, PNC

and PM2.5 measurements are not

representative of each other; and regulating PM2.5 does

little to reduce PNC. This highlights the need

to establish regulatory approaches and control

measures to address the impacts of elevated UFP

concentrations, especially in urban areas,

considering their potential health risks.

https://www.sciencedirect.com/science/article/pii/S0160412019311110

There is the need to evaluate COVID mitigation

as a function of particulate reduction. This is

made more difficult by the finding that all of

our knowledge about air pollution based on

weight can not be converted easily to particle

counts.

Verdex Nanofibers have Advantages in Masks and Air Filters

Verdex is a technology company specializing in mass production of nanofibers for extensive end use applications including air and microfiltration media, high efficiency fuel filtration, advanced filtration, microporous breathable films, micron rated venting films, life sciences/pharmaceutical medias, acoustics, face masks, performance apparel and much more.

Verdex has the ability to spin polymers such as PCL,

PLA, PP, PET, PBT, Nylon 66, and possible others

if melt viscosity is low. This

versatility combined with a unique ability to

simultaneously spin multiple polymers without

using solvents provides unprecedented

flexibility.

The combination of efficiency and high dust

holding capacity makes Verdex HVAC filter

technology a choice for commercial HVAC or clean

room applications. Technology is capable of

achieving efficiencies up to e12 or MERV 12-16.

With lower pressure drop and none of the heath

concerns posed by traditional microglass

composite medias.

Depending on application, the nanofiber layer

can be placed on either upstream or downstream

surface, or as a middle layer of the composite

structure. Verdex HVAC technology is insensitive

to humidity, meaning it is able to retains its

filtration efficiency and low pressure drop

throughout the life of a filter regardless of

the temperature and the humidity. Technology is

the most innovative and sustainable filtration

media across the global HVAC.

|

Product Advantages |

Common Applications |

|

Environmentally Friendly Materials (Glass free & Fluoro free) |

Industrial HVAC filter |

|

Increased filter life through lower pressure drop |

Clean room: HEPA, ULPA grades |

|

Available for both surface and depth filtration |

Transportation |

|

Excellent pleatablility |

Face Masks

Verdex’s nanofiber incorporated face mask

technology is very easy to breathe through due

to its extremely wide surface area created by

the web of nanofibers. It is very effective at

mechanically filtering out PM2.5 particulates.

Conventional electrostatic filter masks’

filtration efficiencies decline dramatically

after it becomes discharged, whereas a nanofiber

face mask provides consistent high efficiency

filtering ability regardless of external

environment.

The

filter material is comprised of a series of

activated carbon filaments, each about 2,000

nanometers in diameter. Each filament is many

times smaller than the typical grain size in

standard carbon materials, making the rate of

adsorption of pollutant gas much faster and

therefore more powerful. It also means that

bacteria and viruses are drawn to the filament

surface much more efficiently, because there is

so much more available surface than in a

granular carbon.

Verdex Face Mask Technology therefore works as

powerful respirators that not only clear the air

of pollution via the particulate filter, but

also remove potentially harmful gases and

pathogens with the additional carbon filter.

|

Product Advantages |

|

Meets the NIOSH N99 standard for filtration, meaning consistent particulate filtration in excess of 99% was maintained (as opposed to the next level down, N95 with excess of 95%) |

|

99.6% filtration of viruses |

|

99.77% filtration of bacteria |

|

Meets the NIOSH standard for inhalation/exhalation meaning that the breathing resistance is within the requirements |

Hifyber Nanofiber Masks Combine High Efficiency

and Comfort

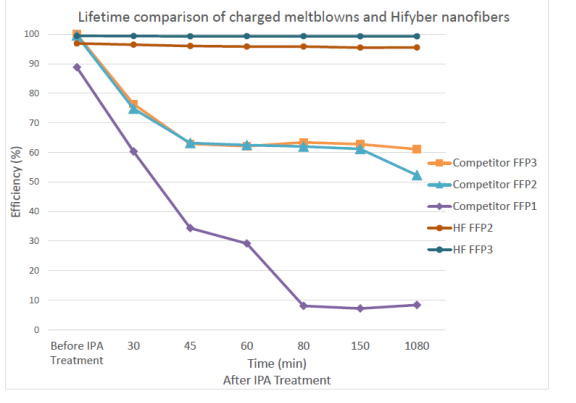

In response to the Covid-19 pandemic, HIFYBER

has developed a nanofiber facemask media,

HF-SPS50-FFP series produced with the

proprietary electrospinning nanofibers and

multilayer design which provides exceptional

breathability and comfort over long periods of

use.

The CDC recommends an N95 filtering facepiece

respirator (FFR) respirator which filters out at

least 95% of very small (0.3 micron) particles,

including bacteria and viruses.

Hifyber has various facemask filter media

options that effectively capture up to 99% of

0.3 micron particles and achieves 99.7% (BFE) /

99.9% (PFE) filtration performance.

HF-SPS50-FFP2 and FFP3 materials have been

tested and certificated by Nelson Labs and NC

State University's Nonwoven Institute in the

USA. Full reports are available in below links:

http://www.hifyber.com/images/technical/BFE-Final-Report-HF-SPS50-FFP2-13.04.2020.pdf

http://www.hifyber.com/images/technical/BFE-Final-Report-HF-SPS50-FFP3-13.04.2020.pdf

Advantages :

- %99,7 Bacterial Filtration Efficiency and

%99,9 Particle Filtration Efficiency-

- The unique media design provides easy

breathability andwearer comfort

- No artificial static charge , it's

mechanically efficient

- High Surface Area

- Excellent Durability and Long Lifetime

Hifyber production capacity is over 1 million m2

per month for the N95 grade facemask.

Fibertex Nonwovens has Nanofiber Products for

Both Face Masks and HVAC Filters

Fibertex Nonwovens expects to generate full-year

2020 revenue of DKK 1,750 million and EBITDA in

the range of DKK 165-185 million. Fibertex

Nonwovens felt the effect of the general

economic decline in Europe during the final

months of the year, and the reported revenue of

DKK 373 million for the fourth quarter of 2019

was in line with the figure for the fourth

quarter of 2018. Full-year revenue still

improved by 8% to DKK 1,705 million, up from DKK

1,574 million in 2018. The revenue improvement

was due primarily to the acquisition of the US

spunlace business in January 2019, which

contributed DKK 140 million, and generally to

growth in North America, whereas tough

competition and subdued demand weighed on

performance in the European markets.

In recent years, Fibertex Nonwovens has

consolidated its position as a leading

manufacturer of industrial nonwovens, and in

2019 the company has strengthened its business

base by making a number of important strategic

and structural initiatives. In addition to

acquiring the US spunlace operations and

expanding capacity by relocating the needlepunch

production line from South Africa, these

initiatives have included starting up

nanotechnology applications, restructuring

production in the Czech Republic and Turkey, and

optimizing production across its European sites.

In terms of development and innovation, the

company has built a solid portfolio of new

projects, including new products for the

automotive and composite industries and for

filtration and acoustic purposes, while steadily

expanding capacity and upgrading production

lines in order to increase the proportion of

value-added products.

The filtration market is turning out to be one

of the most promising markets for Fibertex

Nonwovens. The company’s new filtration media

offer higher filtration efficiency with less

pressure drop than in conventional filtration

products. The greater active surface area of the

nanofibres and minute deviations in pore size

ensure very high filtration material

performance. Potential applications for these

nano-based filtration products include liquid

and air filtration, to filter out bacteria or

pollen, for example. The fibres in the

nanoproducts have a thickness of only 100

nanometres, whereas ordinary nonwoven fibres are

about 100 times thicker.

“We see a huge potential in the filtration

market, and our ambition is to become a leading

global player capable of manufacturing filters

with a wide range of different properties. In

addition, we have the facilities to produce

these products under fully controlled and

certified production conditions ensuring

environmentally-responsible and sustainable

production,” says Jørgen Bech Madsen.

FACE MASKS AND RESPIRATORS MEDIA

|

MEDIA TYPE |

FILTER APPLICATION |

WEIGHT |

THICKNESS |

MASK TYPE |

||

|

|

|

|

|

EN149 |

42CFR84 |

GB32610 |

|

Polyester / other fibres |

Molding layer |

120-130 gsm |

2.0-3.0 mm |

n/a |

n/a |

n/a |

|

Polyester |

Particulate filtration layer |

40-50 gsm |

0.3 mm |

FFP1 |

|

C |

|

|

|

|

|

FFP2 |

N95 |

B |

|

|

|

|

|

FFP3 |

|

A |

|

Polyester / Polypropylene |

Pleatable Respirator media |

100-120 gsm |

0.6 mm |

E12 |

|

|

|

|

|

|

|

H13 |

|

|

Treatments:

Possible treatment options of Polyester and

Spunbond media are:

Hydrophopic/Oleophopic or Antimicrobial

Possible treatment options

of Polyester/Polypropylene media are:

Antistatic, Hydrophopic/Oleophopic or

Antimicrobial

|

MEDIA TYPE |

FILTER APPLICATION |

WEIGHT |

THICk |

MASK TYPE |

|

|

|

|

|

|

|

EN14683-2014 |

ASTM F2100-11 |

|

|

Polyester |

Barrier layer medical use |

40-50 gsm |

0.3 mm |

TypeⅠa |

Level1Barrier |

|

|

|

|

|

|

Typ |

Level2Barrier |

|

|

|

|

|

|

TypeⅡR |

Level3Barrier |

|

|

|

|

|

|

|

N95 |

|

Treatments:

Possible treatment options of Spunbond

soft feel media are:

Hydrophopic/Oleophopic or Antimicrobial

(Does not apply for 100% Polyester soft feel N95

ASTM F2100-11 Standard)

Clean Recirculating

Air Not Sanitation Should be the Top Priority

for Schools

Alexandra Feathers is an epidemiologist, mother

and medical student. In a Stat article she asks

very relevant questions as to why is ventilation

not the top priority at schools? Since is it

very likely that cloth masks are aerosol

generators and that most transmission is through

aerosols the ventilation system with efficient

filters should be the top priority.

The use of N95 masks should be of equal

priority.

Here are her questions.

“My school is not negligent, but like many other

educational institutions, its efforts are

dangerously misdirected. We are collectively

engaging in what Derek Thompson describes in the

Atlantic as “hygiene theater,” in which

organizations looking to reopen focus

intensively on arduous decontamination

strategies to mitigate surface transmission —

even though that is not the primary route for

Covid-19 transmission, and some

scientists argue that there is no direct

evidence the virus spreads this way at all. I’d

also like to add temperature checks to the

hygiene theater playbill, as they too fail to

successfully screen potential Covid-19 carriers

but have somehow made their way onto every

screening list I’ve seen.

Why is this happening? The CDC is supposed to

determine the national priorities for American

health.

Of

the eight bullet points in its “staff safety”

section, four address surface transmission. The

three bullet points dedicated to respiratory

droplets warn people to stay 6 feet away from

each other, cough into their elbows, and wear a

mask.

The current CDC guidance about ventilation is as

follows, “Ensure ventilation systems operate

properly and increase circulation of outdoor air

as much as possible, for example by opening

windows and doors.” But if opening windows or

doors increases the risk

of

asthma, or falling out the window, the

guidelines go on to advise that they should be

closed. That is all the guidance has to

say. It does not mention air filtration, or the

fact that we have pretty good data to suggest

that without addressing air filtration and

circulation, the 6-feet rule

HEPA filters are able to effectively capture

particles the size of SARS-CoV-2. The CDC

currently recommends their use for this

purpose in hospitals, but their capacity to

prevent the spread of Covid-19 in other public

buildings remains under-explored. Though the CDC

has stayed silent on the use of HEPA filters

outside hospitals, on May 25 a group of ENT

doctors made the case for installing them in

doctors’ offices where “aerosol generating

procedures” are being performed, because of

evidence they can help prevent the spread other

infections such as SARS-CoV-1, measles, and

influenza. That was published 108 days before

the first day of school in New York City.

On

May 27, a group of 36 scientists from around the

world in a variety of fields penned

an article in the journal Environment

International titled, “How can airborne

transmission of Covid-19 indoors be minimized?”

As they wrote, “Here, in the face of such

uncertainty, we argue that the benefits of an

effective ventilation system, possibly enhanced

by particle filtration and air disinfection, for

contributing to an overall reduction in the

indoor airborne infection risk, are obvious.”

It’s obvious to me as well and deserves to be

our primary concern in reopening schools, far

more urgently than distance or Lysol. That was

106 days before the first day of school in New

York City.”

https://www.statnews.com/2020/08/05/ventilation-part-of-school-reopening-conversation/