Coronavirus Mask

Decisions

February 19, 2021

Mask Decisions will be Shaped by

in a Multi-Step Process

Mask Use to Continue After the

Pandemic

Expanding the Amount of Filter

Area with

Origami Designs

ICS will have an ASTM F3502 /

Seal Mark

Premium PPE Makes 30 Million

Masks per Month

____________________________________________________________________________

Mask Decisions will be Shaped by

in a Multi-Step Process

The new ASTM standards in the

U.S. and public mask standards

in Europe are a great first step

for mask selection but need to

be incorporated into a

multi-step process. The

ultimate decisions by purchasers

are likely to be made by ratings

from magazines such as

Consumer Reports.

The magazine rates sun tan

lotions not just on the

protection factor appearing on

the bottle but with a

combination of factors which are

more reflective of the

protection.

Will a mass publication such as

Consumer Reports be able

to rate masks with similar

insight?

Earlier this month

Consumers Reports was

anticipating the ASTM standards

and raising the mask leakage as

a major concern. The takeaway is

that if mass media are presented

with the best insights their

advice to readers will be

reflective.

There are minimum safety

standards for cars. However,

safety ratings provided by the

media and experts make safety a

major purchasing factor even

though all cars meet the

minimums. Masks like cars affect

health and life. So most people

will be swayed by reliable mask

safety ratings.

The challenge for the

mask industry is to create a

dependable mask selection

process and then make sure it is

made available.

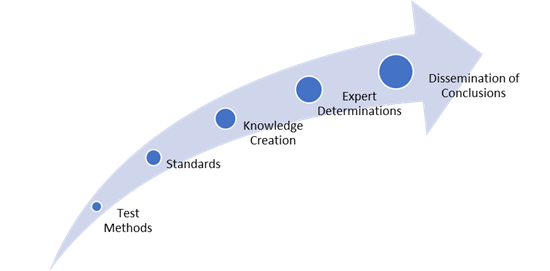

There are a number of steps in

the process.

Multi-Step Mask Selection

Process

Test Methods

ASTM and EU Public Mask

Standards are based on tests

which have widespread

acceptance. ASTM has made a

great contribution by

stipulating tried and true test

methods. The ASTM standards are

based primarily on particulate

efficiency and resistance. These

tests alone will go a long way

toward eliminating masks which

are ineffective. However, there

is still much to be done on test

methods.

1.

Particulate Efficiency:

Coronavirus is a 0.1 micron

particle generally transmitted

in a droplet. That droplet

captured on the interior of a

mask will evaporate or split. So

the initial capture is only part

of the story.

2.

Resistance: The resistance

increases by the square of the

air velocity. Two variables

needing consideration are the

amount of mask filter area and

the breath volume of the wearer.

The concern about a 5 mm H20

limit on resistance is addressed

just by adding a little more

filter area.

3. Fit: Air leakage can exceed 50% in actual conditions of wear. On the other hand custom fitted N95 masks have almost no leakage when tested initially but there is no assurance that an individual will wear it properly.

Surgical masks have large amounts of leakage but with an external brace may reduce leakage to less than 10%. Virus inhalation = particulate inefficiency plus leakage. There is a concern about a particulate efficiency reduction of a few %. That same percent of leakage is just as important.

Fit tests for the public can include use of mobile phone apps which analyze pictures. They can use other remote camera inspections by experts. Novel qualitative tests with perfume, lights, pressure etc. all need to be investigated.

4.

Quality Control:

Eurofins, SGS, Bureau Veritas,

UL, and others are active

worldwide and can provide

quality control seals based on

the ability to inspect

manufacturing

operations around the

globe.

Standards

The ASTM standards are a big

step forward but as new test

methods are developed the

standards will need to be

changed. Also there is a need

for international uniformity in

standards. The use of the

standards by government

organizations such as OSHA is

critical.

Knowledge Creation

There is a great deal of

information about masks being

generated in research papers,

magazines, supplier news

releases etc. The challenge is

to turn information into

knowledge. Associations,

conference organizers, and

publishers can all play a role.

INDA is an association which

holds relevant conferences and

publishes two magazines which

contribute to creating knowledge

on the subject.

Coronavirus Mask Decisions

includes the daily information

with some conversion to

knowledge.

Several search engines

provide an information gathering

function. Webinars further

provide the knowledge

conversion. An intelligence

system provides an organized

approach to knowledge creation.

Suppliers of masks, media,

components, and services should

bear the main responsibility for

knowledge conversion. White

papers are needed. But the

willingness to debate is also

important.

Expert Determinations

Once information has been

converted to knowledge experts

can draw meaningful conclusions.

For example in the CMD

intelligence system there are

extensive analyses and reports

commissioned by Vogmask who has

five mask sizes and is

continuing to improve mask fit.

This knowledge can be the basis

of a conclusion about the

effectiveness of Vogmask versus

a mask with fewer sizes, less

performance testing, and quality

control.

Those organizations involved

with quality control seals can

expand their role. Alternatively

consulting organizations can

provide high level comparisons.

They also have the opportunity

to make these determinations for

a complete safe bubble for which

the mask is only one component.

Dissemination of Conclusions

The suppliers, associations, and

industry media need to make sure

that the appropriate conclusions

are provided to the main stream

media and to user groups. It is

also necessary that the

appropriate conclusions be

conveyed to governmental

organizations. Consider the

power of a conclusion presented

to a city that the mask

efficiency and restaurant

occupancy rate together provide

a risk factor. So 25% occupancy

with the typical 25% effective

cloth mask provides the same

risk as a 90% effective mask and

90% occupancy.

The ASTM standards are a good

start toward a multi-step mask

selection process which will

save countless lives while

creating a huge industry.

Mask Use to Continue After the

Pandemic

Masks may become a mainstay

after the pandemic to help keep

both viruses and pollution at

bay. While masking is already

part of daily life in other

countries, that hadn’t been the

case for the United States. But

a recent National Geographic and Morning

Consult poll signaled a shifting

attitude in the U.S. toward

masking up.

Some 63 percent of 2,200

American adults said they would

continue to always or sometimes

wear a mask while running

errands post-pandemic. A similar

number, around 64 percent, said

they would turn to masks to fend

off air pollution. And 67

percent said they would mask up

during flu season.

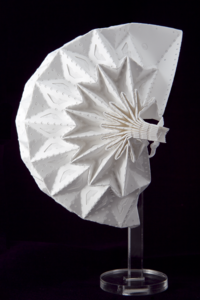

Expanding the Amount of Filter

Area with

Origami Designs

The new ASTM standards specify

the display of the resistance of

the mask material. But this is

based on a specified velocity

through the material. The more

relevant velocity is based on

the amount breathed by an

individual and the amount of

filterable material. If the

individual has lower breath

volume or if the amount of

material is greater then the

resistance will be lower.

Richard Gordon, the founder and

CEO of Air99

LLC.

is one of a growing number of

mask designers who see the

promise of better fit, function,

and even fashion in the ancient

art of origami.

The folds of the Airgami mask

make it easier to breathe by

dramatically increasing the

amount of surface area for air

to pass through. Unfolded, the

filter is two to three times as

large as common N95s.

Finding the right material is

just the first step of crafting

an effective mask. “It doesn’t

matter how good the filter is if

you don’t have a good fit,”

says John

Volckens of

Colorado State University, who

led an intensive

testing effort to document the

filtration efficiencies for an

array of materials.

When improperly designed or

worn, masks can have gaps around

the nose or cheeks, allowing

entry and exit points for

potentially virus-laden

particles to flow—and closing

these gaps is where origami

truly shines.

Origami techniques are already

central to many masks on the

market today, Volckens notes. 3M’s

VFlex,

for example, combines folding

with heat welding to hold the

material together, creating a

more comfortable version of an

N95.

Another solution for holding a

crease is creating an outer

skeleton of stiff material.

Air99's Airgami mask, for

example, is made of a flexible

N95-grade filter fused with a

more rigid and foldable layer.

Since the outer structure

doesn't allow air to pass

through, it's punched with holes

so air can reach the filter

layer.

We need better face masks—and

origami might help (nationalgeographic.com)

ICS will have an ASTM F3502 /

Seal Mark

Mr. Dale

Pfriem, CEO of

ICS advised us yesterday

that his company will be

initiating its Seal Mark program

(traditionally used for sports

eyewear products, etc. as

respiratory devices must be

either CE or NIOSH certified) to

the new ASTM F3502 standard.

“We’ve been testing respiratory

protective devices for over 25

years so we trust our mark will

go to support the new standards

mission to convey confidence to

the market”.

ICS Laboratories is a leading

source for accredited

third-party conformity

assessment of respiratory

protective equipment. ICS tests

respirators, filters, cartridges

and their many associated

devices and accessories to a

wide range of US (NIOSH),

European (EN) and Australian

(AS/NZS) standards. Their

capabilities are extensive and

range from disposable half-mask

filtering face piece respirators

to specialized equipment

designed to protect against

chemical, biological,

radiological and nuclear

respiratory hazards (CBRN).

ICS Laboratories’ scope of

accreditation offers the most

extensive coverage of respirator

test protocols published by the

CDC of any independent

conformity assessment body. ICS

is accredited to perform over 75

NIOSH standard test procedures,

spanning the complete range of

respiratory protective devices

(FFP/N95, APR, PAPR, SAR, SCBA

and SCSR). Their test

reports are accepted by NIOSH as

pre-submittal performance data.

Pre-submittal test results are

required by NIOSH as part of

their approval process

for respiratory PPE intended to

be marketed, sold, or

distributed in the US for

occupational use.

ICS Labs’ expertise in this area

offers its clients endorsed test

reports containing reliable data

and results for globally

relevant standard test method

and performance requirements for

respiratory protection.

Premium PPE Makes 30 Million

Masks per Month

Premium-PPE in Virginia Beach

has invested $5.3 million

to expand and meet increased

demand. That also means new jobs

in the resort city. Brent Dille

is commercial director and has

years of expertise in the

filtration industry. We talked

to him today and learned that he

is moving forward to create the

American Mask Manufacturers

Association . He promised to

provide the details when the

organization launches its

website. Premium PPE has

become a significant mask

supplier.

The CEO of Premium-PPE, a

manufacturer of AmeriShield

branded masks, Vitali Servutas

says like many, they were caught

off guard with COVID-19.

He says when they tried to order

masks, they had a hard time

getting them.

“We couldn’t buy anything in the

United States. We have contacts

overseas in China and we started

importing them and it was very

difficult,” said Servutas.

That’s when one of his partners

suggested they make their own in

Virginia Beach. They were able

to find a machine and, with

their engineering background,

got to work. He says the

operation started in a small

room. Now there’s an entire

warehouse full of machines.

“We were seven employees in the

early days and now we’re over

250. So we’re adding more and

more people every week we’re

running three shifts as well,”

Servutas explained. Now, they

make 1.2 million masks per day

up from 750,000 masks a day

prior to the expansion.

More details on their operation

can be obtained from Brent Dille

at 412- 401-2134. His email is

brent@premium-ppe.com