CATER Mask

Decisions

February 18, 2021

Concentrated Contamination

Capture is the Route to Cost

Effectiveness

ICS is Active in Europe as Well

as the U.S. with Certification

Services

JABIL Delivering Three Ply

Surgical Masks from Memphis

Facility

American Surgical Mask Producing

Up to 150,000 Surgical Masks per

Day

Lanaco is and is Not Sheepish About Their Filters

_____________________________________________________________________________

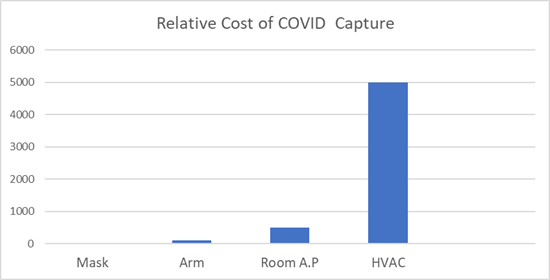

Concentrated Contamination

Capture is the Route to Cost

Effectiveness

There are two ways to battle

COVID: avoidance and or capture.

Avoidance involves lockdowns and

social distancing and should be

minimized if capture will

provide the same level of

safety.

Capture can very cost

effective

depending on the degree

of

Concentrated

Contaminant Capture (CCC)

The cost of capture is a

function of the amount of air

treated and not the amount of

contamination removed So the

goal is CCC.

The ultimate in diluted capture

is the cleanroom. If you have an

entire ceiling of HEPA filters

and you blow air through them

and then provide a perforated

floor to insure all contaminants

flow down and out, then that may

be all you need.

But keep in mind that the

Class 100

cleanroom cost is

typically $1000/ft2. But even

with all this filtered air it is

recognized that people shed

millions of skin particles as

well as potential viruses and

therefore all the cleanroom

personnel have more PPE than

would a surgeon.

It

is well recognized that once

contaminants are dispersed it is

very costly to filter them. The

reason is simple. Cost is a

function of the amount of air

processed and not the amount of

contaminants removed. A mask can

eliminate all the COVID-19

generated by the wearer and

handle less than 1 cfm and a

total cost of a few dollars.

If

a localized capture device such

as the Nederman extraction arm,

described today in

Coronavirus Technology

Solutions, is utilized, most

of the contaminant is captured

with less than 100 cfm.

A

room air purifier in the bedroom

of an infected person can remove

as much contaminant with 500 cfm

as would a house HVAC system

with 5,000 cfm.

If

both transmitter and recipient

are wearing efficient masks then

other measures such as social

distancing become minor by

comparison. All the controversy

over occupancy rates is better

served focusing on mask

efficiency including penetration

and leakage. There is a direct

numerical relationship between

occupancy rate and mask

effectiveness. If people wear

masks which are 60% effective

and the occupancy rate is 60%

the risks is the same as with

people wearing 90% effective

masks and the occupancy rate is

90%.

ICS is Active in Europe as Well

as the U.S. with Certification

Services

ICS Laboratories is a leading

source for accredited

third-party conformity

assessment of respiratory

protective equipment. ICS tests

respirators, filters, cartridges

and their many associated

devices and accessories to a

wide range of US (NIOSH),

European (EN) and Australian

(AS/NZS) standards. Their

capabilities are extensive and

range from disposable half-mask

filtering face piece respirators

to specialized equipment

designed to protect against

chemical, biological,

radiological and nuclear

respiratory hazards (CBRN).

Within the European Union,

regulations mandate that

personal protective products be

CE-certified before they can

legally be placed on the market.

ICS Laboratories is a complete

resource for any manufacturer

seeking to attain CE

certification in order to sell

their protective equipment in

the United Kingdom or Europe.

ICS’ facilities and personnel

enable it to offer the most

competitive prices and lead

times for the requisite EN and

ISO tests that must support CE

certification for PPE. Beyond

the utmost quality test work and

the associated endorsed reports,

ICS Labs truly makes

CE-certification a turn-key

service for their clients,

coordinating documentation and

facilitating assembly and review

of the final technical file.

ICS Laboratories is accredited

to perform conformity

assessments on a wide range of

Category 2 and Category 3 PPE

according to EN and ISO product

standards and test methods. ICS

has cultivated a working

relationship with CCQS UK, a

premier certification

organization. CCQS is a

registered European Notified

Body and is positioned to

efficiently process CE

certifications for products that

are tested by ICS Labs. They

maintain contacts throughout the

world, and operate an office in

the Republic of Ireland,

enabling hassle-free processing

CE-mark processing with regard

to the Brexit narrative.

Working together, ICS

Laboratories and CCQS offer an

integrated resource for personal

protective equipment

manufacturers working to comply

with EU PPE Regulation 2016/425.

Both organizations are

accredited and internationally

recognized as experts at their

respective functions: conformity

assessment and product

certification. ICS not only has

expertise in protective

equipment testing, but through

decades of experience, has also

attained familiarity with

certification programs and

schemes over the world. Their

alliances with highly competent

organizations means that their

CE-certification customers

receive valuable information and

attentive support through the

certification process.

JABIL Delivering Three Ply

Surgical Masks from Memphis

Facility

Jabil announced that together

with its subsidiary medical

device company, NP Medical,

Inc., the company is ready to

deliver personal protective

equipment (PPE) orders of

medical-quality, FDA-cleared,

made in USA face masks, directly

and reliably sourced through

Jabil’s U.S.-based operations in

Memphis, Tennessee. As a

GSA-Schedule holder, Jabil is

positioned to quickly support

the mask mandate recently issued

by President Biden, requiring

individuals to wear masks on

federal property as well as on

planes, trains, buses and at

airports.

“Our work with local and state

governments to fulfill

high-volume orders of PPE made

in the USA means the general

population can get access to

these highly effective masks,”

said Charlie Main, senior vice

president of business

development, Jabil. “Designed to

meet the stringent protection

requirements of operating room

personnel, general healthcare

workers and their patients,

these masks are ideal for

protecting employees and

complying with the mask

mandate.”

The NP Medical nPro™ single-use,

disposable, FDA-cleared

three-ply surgical masks provide

excellent protection and are

designed to meet ASTM F2100-19

Level 1 requirements, providing

over 99% Sub-micron Particulate

(PFE) and Bacterial Filtration

Efficiency (BFE). The masks

feature elastic ear loops, an

adjustable nose wire and

vertically adjustable pleats to

ensure a snug and comfortable

fit.

“Jabil, like so many

manufacturers in America, has

stepped up to the challenges of

the pandemic, including shifting

U.S. facilities to mask and PPE

production, for which there is

much demand,” said National

Association of Manufacturers

President and CEO Jay Timmons.

Jabil is offering these masks as

a directly sourced, reliable

supply of PPE for large orders.

Jabil is a manufacturing

solutions provider with over

260,000 employees

across 100 locations in 30

countries. The world's leading

brands rely on Jabil's unmatched

breadth and depth of end-market

experience, technical and design

capabilities, manufacturing

know-how, supply chain insights

and global product management

expertise.

American Surgical Mask Producing

Up to 150,000 Surgical Masks per

Day

Company CEO Matt Brandman

recently provided insights to

the media about the

masks made locally in

the Tampa Bay area.

“American Surgical Mask is a

U.S. based 3-ply mask

manufacturer based in Tampa, FL.

The company currently operates a

10,000 square foot facility

producing over 150,000 ASTM

Level 1 masks per day.

Their 3-Ply disposable surgical masks are manufactured in Tampa, Florida with US sourced materials. Their executive and management team is highly diverse and minority. Their ownership is highly diversified and consists of professionals with experience in medical, energy, construction and the food/beverage industries.

Their state-of-the-art 10,000 sf

manufacturing facility has been

upgraded to house up to eight

automated machines that are each

capable of producing over 80

masks a minute. Their facility

follows the strictest guidelines

of the CDC to protect their

employees and their families in

this pandemic environment.

Lanaco is and is Not Sheepish

About Their Filters

A

New Zealand Company touts the

benefits of

sheep’s wool with strong

electrostatic charges.

Lanaco makes several

types of masks with varying

efficiencies.

The WAIRE™ P2 respirator

mask must be fitted and adjusted

correctly to your face to

provide the intended

protection.

·

WAIRE™ P2 can also be used in

certain applications against

some bio-aerosols, such as COVID

and FLU virus. Helps protect

against airborne biological

particles - Fluid resistant (120

mm Hg synthetic blood

resistance)

·

Lightweight construction for

added comfort that may increase

wearer time. Has a 4-point head

harness for a secure and

comfortable fit

·

Nose wire allows the wearer to

shape to the nose, reducing

eyewear fogging and forming a

better seal.

·

Made from Lanaco HELIX™ Advanced

Filter Material for effective

filtration with low breathing

resistance (104Pa @ 95l/m)

·

Does not contain components made

from natural rubber latex

·

Protects against hazards, such

as dust, mists, smoke and fumes

·

Complies with AS/NZS

1716:2012 standard and approved

at a P2 level

·

Exceeds 95% filtration

efficiency in laboratory testing

when tested at 95 L/min against

a salt aerosol (VicLab

Australia, INSPEC United

Kingdom)

·

Advanced wool hybrid

electrostatic filter media – low

breathing resistance,

moisture-wicking and naturally

bacteriostatic

Jacobs had a NASA contract under

which it searched around the

world for organizations that

might have the technical

expertise to extend the life of

NASA’s current respirator.

In

May 2018, a call went out to

Lanaco, a New Zealand company

that develops and produces wool

filter material, with a focus at

that point on personal

protective equipment in the

workspace and air pollution

filtration.

The Jacobs team was especially

interested in particle

filtration, which intrigued

Lanaco founder Nick Davenport

because, though his company

hadn’t been working on emergency

breathing devices, he knew wool

was well suited to such an

application.

Davenport, a materials

applications engineer, and his

colleagues had noticed the

interesting properties of wool

while working with polymers

about a decade earlier.

“The deeper we dug into the

science of wool and how it could

perform in an industrial

application, using new science,

the more we saw there was an

opportunity,” he says. Wool is

naturally resistant to fire and

bacteria, and it manages water

well.

Davenport and his colleagues

wondered why this extraordinary

material wasn’t being used for

filtration around the world.

They realized air filter

technology was focused on

synthetic materials, overlooking

this natural alternative.

He

founded Lanaco and developed his

proprietary wool filter

technology. The company has

built up a specialized

commercial flock of sheep by

working with a top breeder to

maximize the qualities that make

good filters and to reduce the

material’s variability.

“We analyzed the wool fiber from

hundreds of different types of

sheep and then established a

breeding program to specifically

focus on the attributes that we

needed to make the world’s best

all-natural fiber air filter for

respiratory applications,”

Davenport says.

Wiles and her team at Jacobs

were looking specifically for a

prefilter that could fit over

NASA’s existing fire cartridge

to increase the life of the

system for Orion. Lanaco then

began to tailor its Helix filter

for the application.

The particles that would fly

around in the event of a

spacecraft fire—including

droplets of water used to

extinguish a blaze—are

potentially small and hot, and

the existing technology is

typically made of polymers with

a relatively low melting point,

Davenport says. A product like

wool, which doesn’t promote a

fire or degrade rapidly under

hot particles, has clear

advantages.

“As a prefilter, our technology

enables the main filter to

function in the presence of

those hot particles and

dangerous gases,” Davenport

says.

Prior to the NASA contract,

Lanaco had not been working

directly in the area of critical

breathing applications. Now the

company has some expertise, with

wool performing particularly

well in fire resistance and

moisture.

We have commenced developing

some of the features in the NASA

application of our filters for

use in critical respiratory

applications,” says Davenport.

Here are additional articles

that can be found in

today’s issue of

Coronavirus Technology Solutions

Extraction Arm from Nederman is

a

Great

CCC

Example

Freudenberg has the Products to

Create Safe Bubbles

Pfizer and Moderna Vaccines Less

Effective Against South African

Variant

Education Week Weighs in

on School Ventilation