CATER Mask

Decisions

February 11, 2021

Double Masking or Knotted Surgical Masks Reduce

Exposure 95%

Bona Fide Mask Expanding U.S. KN95 Distribution

German Chancellor Says, “We Have Lost Control of

This Thing.”

Armbrust American Expanding

Filter Inserts and Pediatric Masks

Ford Developing Clear Respirator

Poor Infrastructure Causes N95 Stockpiling

___________________________________________________________________________

Double Masking or Knotted Surgical Masks Reduce

Exposure 95%

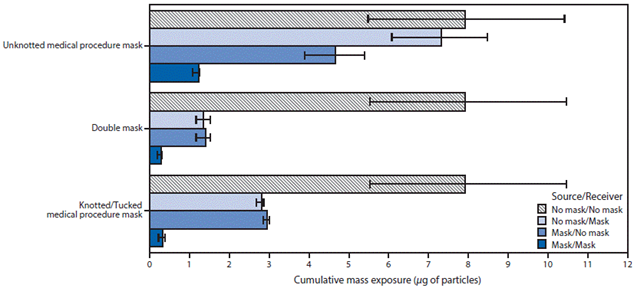

CDC recently conducted

experiments to assess two ways of improving the

fit of medical procedure masks: fitting a cloth

mask over a medical procedure mask and knotting

the ear loops of a medical procedure mask and

then tucking in and flattening the extra

material close to the face. Each modification

substantially improved source control and

reduced wearer exposure.

These experiments highlight

the importance of good fit to maximize mask

performance. There are multiple simple ways to

achieve better fit of masks to slow the spread

of COVID-19 more effectively.

Results from the first experiment demonstrated

that the unknotted medical procedure mask alone

blocked 42.0% of the particles from a simulated

cough (standard deviation [SD] = 6.70), and the

cloth mask alone blocked 44.3% The combination

of the cloth mask covering the medical procedure

mask (double mask) blocked 92.5% of the cough

particles

In the second experiment, adding a cloth mask

over the source headform’s medical procedure

mask or knotting and tucking the medical

procedure mask reduced the cumulative exposure

of the unmasked receiver by 82.2% and 62.9%

respectively. When the source was unmasked and

the receiver was fitted with the double mask or

the knotted and tucked medical procedure mask,

the receiver’s cumulative exposure was reduced

by 83.0% and 64.5%), respectively. When the

source and receiver were both fitted with double

masks or knotted and tucked masks, the

cumulative exposure of the receiver was reduced

96.4%) and 95.9%, respectively.

The full paper is displayed at

https://www.cdc.gov/mmwr/volumes/70/wr/mm7007e1.htm#contribAff

Bona Fide Mask Expanding U.S. KN95 Distribution

Bona Fide Masks™, part of the Ball Chain Mfg.

Co., Inc. family of companies, today confirmed

that Guangzhou Powecom Labor Insurance Supplies

Co., Ltd. (Powecom) will make more of its FDA

authorized KN95 expressly for Bona Fide Masks,

Powecom's premier authorized U.S. distributor.

Bona Fide Masks claims

a

distinguished reputation for trustworthiness,

providing its customers outstanding quality,

service and delivery.

Jing Yip, Powecom's Marketing and Export

Officer, states, "'We are increasing KN95

production for our most important U.S. partner,

Bona Fide Masks. Even during the Chinese New

Year, we will produce and ship masks expressly

for Bona Fide Masks. We are proud to address

U.S. market needs with this unprecedented

production increase, and we highly recommend www.bonafidemasks.com for

purchases of authentic Powecom

KN95s."

Bill Taubner, President of Ball Chain Mfg. Co,

Inc. and Bona Fide Masks, said, "Supply chain

integrity is one of our highest priorities. We

will continue to purchase directly from Powecom.

Powecom masks are of exceptionally high quality

and are currently authorized by the FDA for use

in healthcare settings by healthcare

professionals during the COVID-19 outbreak, in

accordance with CDC recommendations. We ship

from stock at our Mount Vernon, New

York warehouse. There's so much confusion in the

marketplace, and there are so many ‘bad actors'

taking advantage of those in need. Our company

is proud to support our customers during these

trying times."

Guangzhou Powecom Labor Insurance Supplies Co.,

Ltd. (Powecom) is a leading manufacturer of face

masks, folding masks, gas masks, dust

respirators, and ear plugs in China. Their

factory covers an area of 20,000 square meters,

and the company is a recognized leader and

expert in functional masks. At their facility,

Powecom provides large, clean and dust-free

production workshops, as well as sizable

warehouses. They feature an advanced, on-site

testing lab and high-efficiency automatic

production lines, as well as automatic packaging

equipment.

Ball Chain Mfg. Co., Inc. (www.ballchain.com),

established in 1938, is the world's largest

manufacturer of ball chain. Family owned and

operated, the company is the exclusive

manufacturer of ball chain for the U.S.

military's dog tag ID necklace. Ball chain

fabricates millions of feet of ball chain per

week at its Mount Vernon, NY factory for use in

ceiling fans, handbags, light pulls, and a

variety of other applications. At the request of

a local community leader, Ball Chain entered the

mask market and created Bona Fide Masks to

assist with the PPE shortage. The company takes

great pride in everything they do!

German Chancellor Says, “We Have Lost Control of

This Thing.”

Those were the words of Chancellor Angela Merkel

of Germany, surveying the country’s situation in

late January at

a confidential meeting according to an

article in the New York Times She spoke

with typical precision. In Germany, which on

Wednesday prolonged its current lockdown until at

least March 7, things are bad: Since

October, cases have soared — they are only now

starting to come down — and over

50,000 people have died. An atmosphere of

grim resignation prevails.

But wasn’t Germany one of the global leaders in

pandemic control during the first wave? Didn’t

Germans enjoy a fairly normal summer of trips to

the beach and meeting with friends at beer

gardens? Didn’t their children return to school,

as normal, in August and September?

Yes, yes and yes. But when fall came, things

started to go wrong. And it wasn’t bad luck. It

was politics.

Last spring, as the virus rampaged through

Europe, German policymakers acted swiftly and

with rare unity. In March, schools, shops and

restaurants were closed and gatherings of more

than two people banned. After a few weeks, cases

dropped and the country started to reopen

gradually in April and May. Over the summer,

there were very few restrictions — and very

little Covid-19.

But when cases started to rise in the fall,

policymakers failed to repeat the trick. During

the first week of October, the caseload was as

high as it had been when the first lockdown had

been imposed in March. But many explained the

rise by pointing to the increased number of

tests, ignoring the clear trend of cases upward.

Nothing was done.

In the following weeks, the virus took full

advantage of Germany’s complacency. By the end

of October, the number of daily cases had more

than tripled. The response was halfhearted:

closing restaurants and bars but leaving schools

open — a “lockdown

light” that, for a time, stabilized the

situation. It wasn’t until just

before Christmas, at which point cases

were rising sharply, that politicians hit the

emergency brake and closed down the country.

The decision came so late that by early January,

some intensive care units were nearly

overwhelmed. Daily deaths were at times

quadruple their highest point in the first wave.

In the first half of January, the number of

deaths per 100,000 inhabitants temporarily

exceeded that in the United States. The

elderly were devastated: Roughly 90 percent of

those who died in the second wave were 70 or

older.

For a country that had been widely hailed for

its successful handling of the pandemic, it was

a shocking reversal. Why did this happen?

The short answer: politics. In 2021, Germany

will hold six state elections plus the national

parliamentary election in September. If ever

there was a time to take political risks — and

there’s little riskier than depriving weary

citizens of their freedoms for uncertain gain —

the middle of a major election year is not it.

Last spring, electoral calculus was briefly

suspended by the all-encompassing threat of the

virus. That’s no longer the case. Though the

pandemic is far from over, now is a time for

sharpening individual political profiles instead

of compromising, for catering to local

constituents’ special interests instead of

focusing on the national common good. Political

considerations are back.

Those have played out in conflicts among the 16

regional governors and also in tensions between

the governors and the chancellor. One reason for

the country’s slow reintroduction of

restrictions was that the regional heads felt

Ms. Merkel was pushing too hard, aiming at a

show of power.

The troubled vaccination rollout has poured fuel

on the fire. As part of the European Union —

which was slow to agree on a contract with

suppliers and late to begin the rollout —

Germany has struggled to vaccinate its citizens:

Currently only 4

percent have had a vaccine. And when

AstraZeneca, one of the manufacturers, announced

in January that it would cut its supply to the

bloc, political war broke out.

States, the parties in the governing coalition

and the minister of health all frantically

blamed each other — or Ms. Merkel and Brussels.

Germans were left desperately trying to get hold

of a vaccination appointment for their elderly

kin.

After the failures of the past few months,

Germany is in for a marathon. To bring the

finish line closer, a different approach is

gaining traction: A group of experts is

currently promoting a strategy of “No

Covid,” where lockdowns won’t be lifted

until there are fewer than 10 cases per 100,000

inhabitants a week.

It would require sacrifices, but such a strategy

could stop the country from stumbling from one

lockdown to the next through this election year.

Yet it would take courage to prolong

restrictions until cases reached a sufficiently

low level. The decision on Wednesday to extend

the lockdown suggests Germany’s politicians

might be able to act bravely.

But as campaigning gets underway, will they hold

their nerve?

https://www.nytimes.com/2021/02/11/opinion/germany-covid-second-wave.html

Armbrust American Expanding

Filter Inserts and Pediatric Masks

With health experts and elected officials now

advocating for better quality masks to curb the

pandemic, PPE manufacturer Armbrust American is

expanding its line of products to include new PM

2.5+ Filter Inserts, KidSafe Pediatric Masks,

and a bulk mask subscription option for small

and medium businesses, the company announced

today..

.

"The science is clear. The best way to get this

pandemic under control is for everyone to start

wearing better masks that are actually rated to

block particulates as small as the coronavirus,"

said Founder and CEO Lloyd Armbrust. "Especially

with the CDC advocating for children to return

to school in person, manufacturing a mask option

for kids that has a better fit as well as an

option for those who use cloth masks with filter

inserts are two big ways we can help get

everyone properly protected."

Made from N95 meltblown

materials, Armbrust American's new KidSafe

Pediatric Masks are sized for children and those

with smaller faces. KidSafe masks are

also FDA-listed, third-party lab tested at 99%

filtration, and available in

signature American Denim Blue as well as

Pink. Additionally, PM 2.5+ Electrostatic

Filter Inserts are a important addition for

reusable face coverings. The

Filter

Inserts utilize

proprietary Electrostatic Armor Meltblown filter

material, able to block most particulate matter

0.1 microns in size. Plus, they have 25x better

filtration than Chinese-made PM 2.5 inserts,

while also being thinner and using less

material.

Finally, customers also now have the option to subscribe for

regular shipments of FDA-listed American Denim

Surgical Masks (2,000-count) at a deeply

discounted price. Subscribers can also specify

how often they'd like to replenish their supply,

from monthly to every three months (cancel

anytime).

Ford Developing Clear Respirator

Ford Motor Company announced that it is ramping

up new initiatives to help protect people from

COVID-19, including mask development.

Dearborn, Mich.-based Ford designed a

patent-pending, clear respirator in the hopes of

benefitting those with hearing impairments. It

expects the respirator to certify to N95

standards of virus protection.

The transparent, low-cost, reusable respirators

allow people to communicate better by seeing the

full range of human expression, while those with

hearing impairments would be better able to read

lips that are blocked the standard personal

protective equipment (PPE) seen today.

Testing for the transparent respirators to prove

effectiveness is underway and continuing through

the winter, with Ford expecting availability

sometime in the spring.

“One of the things that’s missing during the

pandemic is the power of a smile,” Ford VP,

enterprise product line management and leader of

the company’s Project Apollo PPE manufacturing

effort Jim Baumbick said in the release. “This

clear respirator promises to improve

interactions between neighbors, at the store and

for those who have hearing impairments.”

The company increased its total mask donation

commitment to 120 million masks, an increase

from 100 million, for communities and

organizations with limited access to PPE.

Poor Infrastructure Causes N95 Stockpiling

A year into the pandemic, the disposable,

virus-filtering N95 mask remains a coveted piece

of protective gear. Continuing

shortages have forced doctors and nurses

to reuse their N95s, and ordinary Americans have

scoured the internet — mostly in vain — to get

them.

But the New York Times reports Luis

Arguello Jr. has plenty of N95s for sale — 30

million of them, in fact, which his family-run

business, DemeTech,

manufactured in its factories in Miami. He

simply can’t find buyers.

After the pandemic exposed a huge need for

protective equipment, and China closed its

inventory to the world, DemeTech, a medical

suture maker, dived into the mask business. The

company invested tens of millions of dollars in

new machinery and then navigated a nine-month federal

approval process that allows the masks to

be marketed.

But demand is so slack that Mr. Arguello is

preparing to lay off some of the 1,300 workers

he had hired to ramp up production.

“It’s insane that we can’t get these masks to

the people who desperately need them,” he said.

In one of the more confounding disconnects

between the laws of supply and demand, many of

the nearly two dozen small American companies

that recently jumped into the business of making

N95s are facing the abyss — unable to crack the

market, despite vows from both former President

Donald Trump and President Biden to “Buy

American” and buoy domestic production of

essential medical gear.

These businesses must overcome the ingrained

purchasing habits of hospital systems, medical

supply distributors and state governments. Many

buyers are loath to try the new crop of

American-made masks, which are often a bit more

expensive than those produced in China. Another

obstacle comes from companies like Facebook and

Google, which banned the sale and advertising of

N95 masks in an effort to thwart profiteers from

diverting vital medical gear needed by frontline

medical workers.

What’s required, public health experts and

industry executives say, is an ambitious

strategy that includes federal loans, subsidies

and government purchasing directives to ensure

the long-term viability of a domestic industry

vital to the national interest.

The government needs to call the outsourcing of

America’s mask supply what it is: a national

security problem,” said Mike Bowen, the owner

of Prestige

Ameritech, a Texas mask producer, who has

testified before Congress about the need

to support domestic manufacturers.

Drawing on his experiences during the swine flu

pandemic of 2009, he said many of the start-ups

were unlikely to survive without systemic

change. “We’ve seen this movie before,” said Mr.

Bowen, a 35-year veteran of the industry. “If

and when the pandemic is over, it’s going to be

a freaking blood bath.”

Spurred in part by the wartime

Defense Production Act, domestic

heavyweights like 3M and Honeywell have ramped

up production of N95 masks over the past year,

but the 120 million masks they churn out each

month in the United States cannot satisfy the

health sector’s annual need for 3.5 billion

N95s. Most of the masks made by the big players

are funneled to medical distributors supplying

the country’s large hospital systems.

Smaller companies could help fill the gap.

Together, 19 companies that have recently

received federal

certification produce tens of millions of

masks a month; Northwell Health, a large

hospital chain, has been using a total of

300,000 masks a month in its 23 hospitals.

The businesses include Protective

Health Gear, a New Jersey start-up

founded by a chiropractor and a store display

executive that has been struggling to find

steady customers, and ALG

Health, a lighting company that produces

1.5 million masks a month in Bryan, Ohio, but

can’t obtain the final investment needed to

fulfill its goal of producing 30 million a

month.

Unlike his predecessor, Mr. Biden has made face

coverings a key component of his plan to contain

the pandemic. In one of his first

acts as president, Mr. Biden directed

federal agencies to aggressively use the D.P.A.

to boost domestic manufacturing of

personal protective equipment, and a subsequent executive

order seeks to encourage the government

purchase of domestically made goods. Still, none

of the half-dozen start-ups interviewed for this

article said they had been contacted by federal

officials.

I’m encouraged by the Biden administration’s

initial steps,” said Scott Paul, president of

the Alliance

for American Manufacturing, an industry

group. “But the federal government really needs

to step up its game and provide certainty to

American companies that answered the national

call to action, not just for this crisis, but

for those in the future.”

Tim Manning, the White House’s Covid-19 supply

coordinator, said the administration would

announce a number of new D.P.A. contracts for

personal protective equipment in the coming

weeks, but that the larger supply-chain issues

would take longer to address.

“One of our priorities in our pandemic response

is doing this in a way so we can ensure the

industrial base expansion that has happened can

be sustained, so we don’t end up in the same

situation the next time,” Mr. Manning said in an

interview.

Companies like United

States Mask, a start-up in Fort Worth,

Texas, which began producing N95s in November,

may not be able to hold out much longer. John

Bielamowicz, a commercial real estate broker who

started the company with a friend, David

Baillargeon, in the early weeks of the pandemic,

said he has been frustrated by the lack of

interest from the hospital chains, long-term

care facilities and local governments that buy

in bulk.

Although the company’s masks have been certified

by the National Institute for Occupational

Safety and Health, a division of the Centers for

Disease Control and Prevention, Mr. Bielamowicz

says many buyers are reluctant to give

unfamiliar products a try. Big hospitals prefer

to stick with masks they already use because of

the time-consuming need to fit-test new models

on employees. But many cost-conscious bulk

buyers prefer to purchase cheaper Chinese ones.

One of the more painful

rebuffs came from Tarrant County, where

Mr. Bielamowicz’s factory is located. Last month

the county disqualified his company’s bid

because officials wanted to buy specific

Chinese-made models. County officials did not

respond to requests for comment.

“We got into this business because we were

troubled by America’s dependence on foreign

manufacturing and wanted to do something about

it,” said Mr. Bielamowicz, whose masks sell for

$2.25 a piece — a few cents more than those made

in China. “Are we going to be left to die on the

vine when we’re making N95s at a competitive

price?”

As they hold out hope for intervention from

Washington, United States Mask and other N95

producers said that the ability to sell to the

public through online retailers like Amazon

would help them stay afloat.

Dr. Monica Gandhi, an infectious disease

specialist at the University of California, San

Francisco, said the vast majority of Americans

who have embraced mask-wearing and are concerned

about new variants would eagerly upgrade to N95s

or other kinds of virus-filtering masks if

they were available.

“Right now, high-filtration masks are more

important than ever,” she said.

The problem is getting consumers to their retail

websites. At the moment, anyone trying to buy

N95 masks on Google Shopping or Facebook

Marketplace is greeted with a blank page; on

Amazon, a search for N95s yields a welter of

vendors hawking KN95 masks, a Chinese-made

equivalent that researchers say is less

effective. As of Wednesday, the site seemed to

be allowing a handful of masks described as

N95s, but not all are listed on the N.I.O.S.H.

website. Another included a disclaimer saying

the masks are not recommended for use against

Covid-19.

Google and Facebook said

they had no immediate plans to change their policies,

which are based on guidance from the C.D.C.

and the World

Health Organization aimed at ensuring

health care workers have adequate protective

gear. Amazon did not respond to requests for

comment.

Lance Brown, the chief executive of Rhino

Medical Supply, a distributor in South

Carolina, has been singularly focused on selling

N95s produced by the new generation of American

entrepreneurs. Their masks, he said, are

superior to most of those made in China, but his

appeals to national pride often fail to move

institutional buyers focused on the bottom line.

Mr. Brown has also been pushing for online

retailers to reconsider their sweeping bans on

N95 masks. The problem, he said, could be easily

fixed by creating exceptions for masks certified

by the government.

“How is it that you can spread conspiracy

theories on Facebook, but we can’t sell N95

masks to the millions of Americans who need them

right now?” Mr. Brown asked. “I can understand

Facebook not wanting to sell masks made by some

guy in his garage, but these masks meet strict

N.I.O.S.H. guidelines.”

Mr. Bielamowicz, for one, has discovered the

benefits of a little public exposure. Last

month, as he and his partner were considering

whether to throw in the towel, a local newspaper

columnist wrote about their tribulations.

The company was immediately overwhelmed by

orders from school nurses, cancer patients and

essential workers, many of whom said they had

given up on finding N95 masks.

Within three days, the company had sold out its

entire stock of 250,000 masks.

https://www.nytimes.com/2021/02/10/health/covid-masks-china-united-states.html