CATER Mask

Decisions

February 10, 2021

Mask Policies Need to be Revised

NXTNano Can Contribute Nanofiber Advantages

Armbrust American is Ready to Step Up with

Substantial Production Increases

TMS Can Increase Production by 16 Million per

Month

Shortage of N95 Masks for Medical Workers Still

Exists

ASTM Standard for Respiratory Fit will Encourage

Better Designs

NIOSH September Observations on EHMPRs

SPG Tests Show That Flat Fold N95s Provided

Better Seal Than Cup Shaped

Eight Million Deaths Caused by Polluted Air Each

Year

___________________________________________________________________________

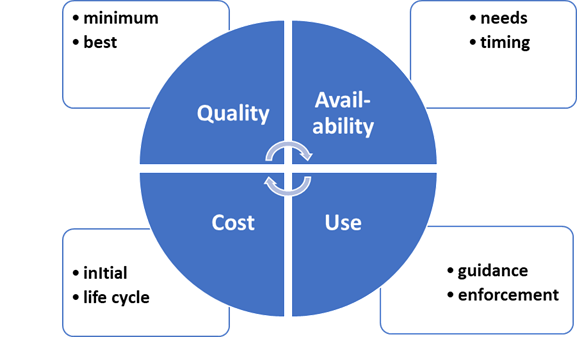

Mask Policies Need to be Revised

The initiative for OSHA was covered in the Alert

yesterday.

There is agreement that

tight fitting efficient masks will save

thousands of lives which will otherwise be lost

by people wearing cloth masks. Erick Couch is

working with INDA and McIlvaine to present

evidence which could be helpful in guiding the

Biden Administration to create appropriate

policies and funding. Facts and insights are

needed in four areas.

QUALITY:

Minimum standards such as being issued by

ASTM provide the first step in insuring quality.

Expert guidance will result in the best choices

using both qualitative and quantitative

methods. The role of government will be

to embrace the minimum standards and to

encourage the reliance of purchasers on expert

advice. Air leakage, breathability, and particle

removal are all important.

USE: The motivation has to be push and pull.

Push or enforcement has to be minimum standards

such as ASTM. Pull can be education as to the

advantages of effective masks but also the

creation of safe bubbles where with effective

masks more normal life can be enjoyed.

AVAILABILITY: The mask need assessment should

include uses by the medical profession,

other countries, and for other

applications as well as for the U.S. public. The

timing by which additional masks can be made

available needs to be determined.

COST: Initial mask cost and life are needed to

assess total cost. Since mask deterioration with

time may be slow and steady there is opportunity

to decrease cost and increase

availability.

NXTNano Can Contribute Nanofiber Advantages

NXTnano supplies nanofiber media for masks and

cites the life as well as efficiency as

attractive features.

Here is our interview with Andy McDowell.

Bob: What is the relationship between NXTnano

and suppliers of masks?

Andy: NXTnano works very closely with our

mask/respirator customers to down-select the

filtration media of best fit depending on their

design. Often times we will even help manage the

testing of the products through SGS or Nelson

for them, with all of our lab equipment we can

make sure their products are testing well before

going out to the labs. Once we do send them

out, we’ve looked at so many results now and can

help our customers spot pitfalls or

inconsistencies to avoid unnecessary delays. For

programs where there is N95 approval being

sought we see them as strategic partners, our

technology is effectively locked in when they

receive approval.

Bob: Since a nanofiber media mask does not rely

on a temporary electrostatic charge what is your

estimate of reusability?

Andy: We have done several studies on this

now, most recently our employees wore one of our

customers (Filti) respirators for eight hour

shifts, for five days straight. We measured the

initial efficiency, then the efficiency every

morning before they wore it again. After day one

we lost a few percentage points of efficiency,

but overall the respirators were performing very

well. After this initial loss, which was likely

inherent static, they leveled off. After five

days we called it, the respirators we getting

dirty from general handling, food, makeup etc.

but the efficiency was still over 90% on the

TSI.

Bob: Explain the range of efficiencies and

related resistance which are available.

Andy: At the moment we are most commonly

producing material to the N95 standards, in a

finished respirator form using our nano I expect

to see resistance values of 10-12 mm of H2O at

85 L/min flow with 97%-98% efficiency on the TSI

with 0.26 micron NACL (mean mass). It’s easy

enough to go down the scale and produce less

restrictive media; with something at

65-70% efficient (0.26 micron NACL) at 85 LPM

our restriction can be as low as 2.5 mm. if you

plot those two points out, establish a trend

line the fit between them and then check against

actual produced materials you will find the

“fit” is quite linear. So for a customer this

translates to a conversation of: I must have

“x" efficiency, or I must have less than “y”

pressure drop.

Bob: If an unlimited market were available how

much production could you achieve in four

months?

Andy: Our nano lines are running 24/7 right now

but we are keeping up and making running

productivity improvements weekly. When we last

talked the conversation was what would it take

for NXTNano to add more lines, we have now

pulled that trigger. Line 4 will be up in April,

and line 5 is looking like June with the option

to take it to possibly 130” wide instead of our

current 80”. The average through put we see for

customers is about 250,000 respirators / per

machine / per week on an eight hour shift. For

us that’s about 12,500 sq meters of material

they need per week per shift, which is only

around six hours of run time on one of our

lines. As we add capacity we will easily grow

with our mask customer base. For our customers,

several of them have the capability to turn out

several million masks per week based on their

current equipment, and additional equipment can

generally be added and running in 60-90 days.

Bob: What are the limiting factors in terms of

obtaining electrospinning equipment for media,

mask machines or other products and services?

Andy: Most of what people are doing in

electrospinning is at the lab scale. For serious

volume production there are only a handful (less

than 5) companies to select from globally. Most

of the equipment I’ve seen simply won’t support

economical manufacturing both from a throughput

perspective and an uptime perspective. Those

that will, are proprietary designs heavily

guarded, and rightfully so, by the companies

that operate them. Mask machines aren’t exactly

hard to get ahold of, there are domestic and

offshore options. What we have seen most

commonly is a structural issue in knowledge -

people know the mask they want to make but don’t

necessarily understand how to get home on

performance of the mask.

Armbrust American is Ready to Step Up with

Substantial Production Increases

Lloyd Armbrust

replied to the Couch request with a

forecast

of substantial production increases should

funding be available “We originally designed our

Texas facility to produce 1.4 Billion masks

annually, complete with vertical integration

making all of the nonwoven fabric in house. We

are partially through this building process

having already invested nearly $10M.

Additionally, we have real MEPCA implementation

plans, existing factory space, plus many of the

machines actually on the ground here in Texas.

“In fact, I would bet that we are the only

company in the world that has nonwoven equipment

capable of producing 300 tons per month ready

to be hooked up in less than 30 days’ time in

the US. The only issue is that our current

FDA-registered facility doesn't have the

appropriate power requirement. Because of this,

we decided to build a new facility which has

pushed our production timeline back. However, we

have all of the original plans and approvals to

move forward with our existing facility if we

wanted to pay to the premium price to bring

4000amps of power into that building.

TMS Can Increase Production by 16 Million per

Month

Dan Grayson replied to the Couch request.

He estimates that with government funding

production could be

increased by 16 million masks per month

over the next four months.

Shortage of N95 Masks for Medical Workers Still

Exists

There is a shortage of N95 mask. So Don Milton,

MD and Professor at the University of Maryland

thought it was notable that

FEMA has authorized US N95 manufacturers to

export 1 million N95 masks per month.

The main focus of the Alert today is to address

the potential with OSHA and masks for the U.S.

public. But we need a holistic approach. If

there is still a shortage of masks for medical

workers then it will be more challenging to

suppl masks to the public.

Also until the poorer countries have masks or

vaccines, the U.S. will be impacted economically

but also by the transmission of new variants.

The poorer countries also account for the

majority of the 8 million people per year dying

due to air pollutants (see article in this

Alert). So mask demand has to be viewed

holistically from a geographic and application

perspective.

A year ago, hundreds of desperate consumers were

emailing Mike Bowen's Texas medical supply

factory every day, looking to buy N95 medical

respirator masks that can filter viruses:

"Scared Americans and moms and old people and

people saying, 'Help me,' " Bowen recalls in an

interview with NPR.

Today, most consumers still aren't able to buy

N95 masks because the supply available to

retailers remains very limited. Even hospital

workers are still being asked to ration

and reuse their supplies of N95s, and the

website of the Centers for Disease Control and

Prevention says,

"N-95 respirators should not be used [by the

general public] because they should be conserved

for healthcare personnel."

Meanwhile, consumer demand for N95s and

medical-grade, surgical-style masks keeps

growing as the Biden administration emphasizes

the use of masks by the public to slow

the spread of the coronavirus — especially as

new variants of it spread rapidly around the

world.

From the start of the coronavirus pandemic,

Bowen's company, Prestige Ameritech, and most

other makers and distributors have prioritized

supplying health care workers, who say they

still don't have enough masks and other personal

protective equipment.

The Biden administration has

invoked the Defense Production Act to

prioritize production of N95s and other medical

supplies. But even with those measures, U.S.

hospitals remain worried about their supply of

these medical masks — more formally called

respirators — despite efforts by factories to

churn out billions more.

The story of N95 production over the last year

in many ways reflects shortages seen throughout

the U.S. medical supply during the pandemic —

from ventilators and exam gloves to syringes and

vaccines. The demand is global and sustained,

putting pressure on a fragile supply chain that

remains stressed and unable to keep up.

"Global demand continues to outpace production,"

says Nancy Foster, vice president of quality and

patient safety at the American Hospital

Association. Availability of N95 masks has

improved since last spring, Foster says, but "we

are continuing to use conservation measures

within hospitals to protect the supplies we

have, to extend the wear of N95s designed for

one-time use." That includes asking

hospital workers to wear each mask longer.

Costs for N95s — and other medical supplies,

like medical

gloves and gowns — have at least doubled.

The use of N95s has increased 500% since July, according

to Premier, a company that buys medical

supplies on behalf of about 40% of U.S.

hospitals.

"In most of the hospitals, nurses are wearing

their N95s for five shifts," or up to 60 hours,

says Mary Turner, president of the Minnesota

Nurses Association and an intensive care nurse

working with COVID-19 patients. "It's becoming

the norm to not wear N95s the way they're

supposed to be used."

A November

survey by National Nurses United found

the lack of protective gear like N95s remains a

huge safety concern for its members. More than

80% of nurses reported reusing single-use items

like N95 respirators, and about 20% of hospitals

had recently limited the use of N95s.

Before the pandemic, there was little consumer

demand for these products. Purchasers included

people with compromised immune systems or others

working in wildfire

areas or on dusty home improvement projects.

That has changed. Everyone — from front-line

grocery workers to travelers to teachers to

people visiting vulnerable family members — is

looking for the specialized masks.

N95s are the gold standard in masks because

unlike cloth, surgical and KN95 alternatives,

they're tested and approved by a federal agency

as having demonstrated that "they can filter out

a minimum of 95% of airborne particles under

worst case test conditions," according

to the CDC.

Nonetheless, N95s are still rarely available to

consumers.

Shepard Medical Products,

an Illinois-based company that sells supplies to

drugstores and other retailers, hasn't sold a

single N95 since March of last year. That's when

makers of N95s called the company's president,

Chris Humbert, to tell him, " 'We're done — we

won't have any more product available for 2020.'

"

So far this year, Humbert says, that shortage

hasn't yet eased. Some wholesalers large enough

to order directly from factories in China

occasionally can get N95s to sell at hardware

stores, for example, but "it's still very

fragmented." The priority, he says, has been to

supply health care facilities and government

agencies. "I stopped trying, until hospitals are

covered."

Fraud is also a major concern. Everyone, from

nurses, hospitals, manufacturers and

distributors, says vetting fake suppliers or

identifying copycat N95 masks has been a huge

concern.

Humbert says many new upstarts tried to sell him

products billed as N95s, but because he couldn't

verify their quality or efficacy, he decided it

would be safer to remain out of stock.

"We didn't like being out of stock and

disappointing any of our customers by not being

able to supply, but we did not feel that we had

a reliable source that could provide those

products for us on par with the product that we

had in place," Humbert says.

Exactly when American consumers might once again

gain broader access to N95s depends on a lot of

factors.

"I think if the vaccine rolls out faster, you're

going to be able to get N95s faster," as the

risks diminish and fewer people need N95s, says Kaitlin

Wolak,

a supply chain expert and assistant professor at

the University of Notre Dame. (Public health

workers urge even those immunized to continue

pandemic precautions — including consistent

mask-wearing — for now, until the

pandemic is tamed.)

Broader availability of N95s also depends on

manufacturing speed, Wowak notes, and on when

backlogged orders from hospitals and other

medical facilities can be filled.

The Biden administration has touted its plans to

use the Defense

Production Act to stimulate

production. Wowak says that might mean

manufacturers get more federal help finding the

raw materials needed or coordinating

distribution of supply. But it won't address

some of the main challenges that affect the

speed of manufacturing.

Wowak says how fast products like N95s are made

is determined by three primary factors: the

complexity of the equipment used to make the

product, the availability of raw materials and

the availability of trained workers.

Making vats of hand sanitizer at a rum

distillery, in other words, is very different

from ramping up an N95 factory, because of the

cost and complexity.

Managing those costs and complexities has made

the past year extremely busy for Mike Bowen, the

co-owner of Prestige Ameritech. He and his

partner started the company in 2005; it is one

of the few makers of N95s based in the United

States. Demand overwhelmed his factory a year

ago when China stopped exporting the masks that

most U.S. hospitals relied on for most of their

supply.

"I've gotten requests for maybe a billion and a

half masks if you add it up," Bowen

told NPR in late February of last

year. At the time, Bowen's company could produce

75,000 N95s a month.

He was troubled by the influx of orders, he

said. They put him in a bind.

To make more N95s, Bowen would need new mask

machines, each of which takes four months to

custom build and costs as much as $1 million. To

justify building extra machines, he needed

assurance that U.S. hospitals and government

agencies wouldn't just go back to buying cheaper

Chinese-made masks once the pandemic was over.

He'd been burned before. A decade earlier,

during the H1N1 flu pandemic, Prestige had made

what Bowen called "the mistake" of investing in

new machines and ramping up production for a

need that dried up as suddenly as it began.

"One day — and it is literally one day — it just

quits," Bowen told NPR last spring. "The demand

is over."

He eventually did decide to expand last spring,

as the COVID-19 pandemic worsened.

Bowen asked U.S. hospitals to sign multiyear

deals for N95s. That gave him the funds to build

nine new N95 machines, some of which are still

coming online. The factory now makes 80 times

more masks than it did a year ago.

"We're now selling 6 million [a month], and we

have another 4 million coming on board," he

says.

For the first time in a very long time, Bowen

says, he has some excess supply he could start

selling into the consumer market.

ASTM Standard for Respiratory Fit will Encourage

Better Designs

An evaluation of the new ASTM standard was

posted on the NIOSH website January 26,

2021 by Christopher Coffey, PhD; Lisa Brosseau,

ScD, CIH; M. E. Bonnie Rogers, DrPH; and

Jonathan Szalajda, MS.

One of the most important criteria for any

filtering facepiece air-purifying respirator to

be effective is that a good seal is formed

between the respirator’s facepiece and the

wearer’s skin. The ability to achieve this seal

is called the respirator’s fitting

characteristic.

In 1995, when NIOSH put Title 42 Code of Federal

Regulations Part 84 (42CFR84) into operation, it

did not include an evaluation of the fitting

characteristics of respirators approved only for

particulates.1 In addition, no

voluntary consensus or other government-unique

standards existed to evaluate the fit capability

of a filtering facepiece respirator prior to it

being used in the workplace in an OSHA-regulated

fit testing program. Therefore, several studies

have been conducted to determine how well

NIOSH-approved particulate respirators,

especially filtering facepiece respirators, fit

wearers.2-8 These studies found a

high number of filtering facepiece respirators

on the market at the time had poor fitting

characteristics. Filtering facepiece respirators

that do not fit most employees place an

unacceptable burden on respirator program

administrators, who must then provide many

models and sizes to ensure that every wearer can

find a respirator that fits properly.9 In

addition, poorly fitting respirators increase

the number of fit tests required, increasing

costs.10

The ASTM RFC Standard will enable respirator

manufacturers to develop better designed models

that fit the worker population. Respirators

passing the RFC Standard test method are

expected to have better fitting characteristics.

The RFC standard will lower costs to respiratory

protection programs by reducing the number of

different models needed in the program.

Purchasers of particulate-only respirators could

reference ASTM F3407 in their procurement

packages to ensure receiving those with good

fitting characteristics. The RFC Standard can be

used by organizations, such as NIOSH, to ensure

a minimum performance level of for all

respirators used within an approval program.16 Both

conventional respirator designs as well as novel

respirators (such as ones without the prevalent

two-strap head harness to provide adequate

tension during use and even distribution of

pressure) can be evaluated using the RFC

standard.19

Ultimately, this RFC Standard defines

performance requirements that could be used as

part of a conformity assessment program to

ensure that NIOSH-approved respirators will fit

a specified percentage of the intended user

population, thus providing workers with better

protection. This is crucial in all industries in

which workers are exposed to a variety of

agents, one of the most notable examples being

the Healthcare and Social Assistance industry

sector. Healthcare workers may be exposed to

biological agents, e.g., seasonal influenza,

Ebola, Severe Acute Respiratory Syndrome (SARS),

Influenza A H1N1, and more recently SARS-CoV-2,

the virus that causes COVID-19, as well as to

chemical agents.17-19

ASTM F3407 can be read for free at https://www.astm.org/COVID-19/ or

purchased at https://www.astm.org/search/fullsite-search.html?query=Respirator%20fit%20capability.

NIOSH September Observations on EHMPRs

The high demand and limited supply of N95

filtering facepiece respirators (FFRs) during

the COVID-19 pandemic have led organizations to

rely on other types of respirators, such as

reusable elastomeric half mask respirators (EHMRs).

Photo Courtesy of MSA

An EHMR is a non-powered NIOSH-approved

respirator that has a tight-fitting facepiece

that covers the nose and mouth.1 The

facepieces are made of synthetic or natural

rubber material permitting repeated cleaning,

disinfection, storage, and reuse. EHMRs use

replaceable filters or cartridges, and they

provide the same, or greater, level of

protection as single-use N95 FFRs. While EHMRs

have been used in many workplace settings for

years, their utility in healthcare settings has

not been as common.

CDC developed strategies to optimize the supply

of EHMRs during conventional and surge demand

situations, as experienced during the COVID-19

pandemic.1 NIOSH-approved EHMRs

provide an alternative respiratory protection

option capable of reducing the total number of

respirators required because EHMRs may be

cleaned, disinfected, and reused numerous times.1 Unless

the EHMR filter cartridges become visibly soiled

or wet, visibly damaged, or if the respirator

becomes notably harder to breathe through,

current practice shows that conservatively, the

filters could be used for at least one year.1 Although

more popular in industry settings, EHMRs have

been leveraged both before and during the

COVID-19 public health emergency and have been

highlighted in several recent media reports.2-5

Although EHMRs require a higher up-front cost

than N95 FFRs, the EHMR facepiece and cartridge

reusability may provide cost-savings advantages

and may create less hospital waste compared to

the disposable N95 FFR.6 For example,

due to COVID-19 N95 FFR shortages, one large

academic medical center—comprising 12

hospitals—purchased and deployed 10,000 EHMRs

that reduced N95 FFR usage to zero.7,8 The

center reported a significant cost benefit. The

one-time cost and storage of EHMRs was 10 times

less expensive after one month of use when

compared to disposable N95 FFRs.7,8

Research has shown that user acceptance, fit

testing, and disinfection are not barriers

to implementing EHMRs.9-12 With

proper use, fit, and maintenance training, EHMRs

provide an effective solution to supplementing

the supply of N95 FFRs.

Generally, EHMRs have exhalation valves, which

should be taken into consideration before use in

a sterile setting or for use as source control.

Until more research is available, masks with

exhalation valves or vents should NOT be worn to

help prevent the person wearing the mask from

spreading COVID-19 to others (source control).

Here are some tips when it comes to exhalation

valves:

-

Wear a respirator without an

exhalation valve when both

source control and respiratory

protection are required.

-

If only a respirator with an

exhalation valve is available

and source control is needed,

cover the exhalation valve with

a surgical mask, procedure mask,

or a cloth mask that does not

interfere with the respirator

fit.

https://blogs.cdc.gov/niosh-science-blog/2020/09/08/elastomeric/

SPG Tests Show That Flat Fold N95s Provided

Better Seal Than Cup Shaped

Twenty subjects underwent quantitative

respirator fit testing with two styles (flat

fold, cup-shaped) of N95 filtering facepiece

respirators (N95 FFRs). Passing a fit test was

followed by stereophotogrammetry to determine

the face seal area and computation of seal

pressure. There were significantly different

seal pressures (p < 0.01) between standard size

flat fold and cup-shaped N95 FFRs but no

significant differences in face seal area. No

significant differences were noted in fit

factors, but more individuals passed fit testing

wearing flat fold respirators. The ability of

flat fold N95 FFRs, at lower seal pressures, to

obtain similar fit factors as cup-shaped N95 FFR

at higher seal pressures offers the possibility

of enhanced facial comfort without a loss of

protection. Stereophotogrammetry offers a

relatively simple, non-invasive technology to

evaluate various properties of N95 FFR fit.

SPG enables the determination of geometric

properties from photographic images. This

process involves estimating the

three-dimensional (3D) coordinates of points on

an object. Photographs are taken from multiple

locations (lines of sight) and, using the

principle of triangulation (mathematical

intersection of lines of sight), the X, Y, and Z

coordinates of each point of interest are

determined.

https://www.ncbi.nlm.nih.gov/pmc/articles/PMC4545596/

Eight Million Deaths Caused by Polluted Air Each

Year

New evidence on the harm caused by air

pollutants needs to be considered when

creating HVAC and mask strategies.

More than eight million people around the world

die each year as a result of breathing polluted

air that contains particles from fossil fuels, a

new study has found.

Burning fossil fuels such as coal and oil

produces greenhouse gases that trap solar

radiation in the atmosphere and cause climate

change. But it also releases tiny poisonous

particles known as PM2.5. Small enough to

penetrate deep into the lungs, these particles

can aggravate respiratory conditions like asthma

and can lead to lung cancer, coronary heart

disease, strokes and early death.

Research has also found a link between higher

levels of long-term pollution and more deaths from

Covid-19.

In a study published in the journal

Environmental Research on Tuesday,

researchers from Harvard University, in

collaboration with the University of Birmingham,

the University of Leicester and University

College London, found that exposure to

particulate matter from fossil fuel emissions

accounted for 18% of total global deaths --

almost one in five -- in 2018.

The figure is much higher than previously

thought. As recently as in 2019, scientists were

estimating that 4.2 million people die each year

from outdoor airborne particulate matter

pollution, a figure that included people who die

because of pollution from dust and smoke from

wildfires and agricultural fires.

The new study shows that in 2018, estimated 8.7

million deaths were linked to fossil fuel

emissions alone

Eloise Marais, an associate professor in

physical geography at UCL and a co-author of the

study, said the research adds to the "mounting

evidence" that air pollution from fossil fuels

is detrimental to global health.

"We can't in good conscience continue to rely on

fossil fuels, when we know that there are such

severe effects on health and viable, cleaner

alternatives," she said in a statement.

The scientists used a global 3D model of

atmospheric chemistry developed at Harvard to

get a better picture of pollution at a more

local level.

Traditionally, satellite and surface

observations were used to estimate the average

global annual concentrations of PM2.5 particles

in the air. By using the 3D model, the

scientists were able to divide the globe into a

grid with boxes as small as 50 kilometers by 60

kilometers (31 miles by 37 miles) and look at

pollution levels in each box individually.

This allowed them to assess the impact of the

pollution in places where people live and to

distinguish between different sources of

pollution.

They found that China, India, parts of the

eastern US, Europe and Southeast Asia were the

worst impacted. According to the data, as many

as 30.7% of deaths in Eastern Asia, 16.8% in

Europe and 13.1% in the US can be attributed to

fossil fuel pollution.

To model the pollution, the researchers used

real emissions and meteorology data, mostly from

2012. The year was picked to eliminate the

influence of the El Niño phenomenon, which can

worsen or improve pollution depending on the

region. They then updated the data to reflect a

44% fall in fossil fuel pollution in China

between 2012 and 2018.

The researchers estimate that China's move to

cut its fossil fuels emissions saved 2.4 million

lives worldwide, including 1.5 million in China.