CATER Mask

Decisions

February 9, 2021

Capability to Provide Efficient Masks to all

Americans

The Opportunity is Huge and Many Lives will be

Saved

Request from Eric Couch for Submittal to OSHA

Capabilities of U.S. Mask Makers to Expand

Production

______________________________________________________________________________

Capability to Provide Efficient Masks to all

Americans

The Opportunity is Huge and Many Lives will be

Saved

Coronavirus Mask Decisions

has long been stating that tight fitting

efficient masks can halt the pandemic. The

medical community has now come to the same

conclusion. The average mask worn in public as

shown in a Patient Knowhow survey is only 20%

effective. So an immense change in mask type is

needed.

ASTM has worked hard on efficacy

standards which it will publish next month. Two

levels of efficiency are specified. More

importantly the standards will provide a

measurement structure by which the most

effective masks can be selected.

The Biden Administration is committed to masks

as a solution. Several different agencies are

involved in shaping the government initiative.

There is the potential for minimum efficacy

standards and for government funding. The

following is an email regarding how suppliers

can interface with government agencies to

achieve the desired results.

It is followed by an analysis prepared by

McIlvaine and then background information from

mask suppliers.

Comments are being solicited from mask

suppliers. This Alert along with mask supplier

comments will be submitted by McIlvaine to Erich

Couch and INDA for further submission to OSHA.

Request from Eric Couch for Submittal to

OSHA

Eric Couch is working on the quick supply of

efficient masks to

everyone and is coordinating efforts with

various government agencies. There is the

opportunity to obtain government endorsement of

minimum efficiency levels and to also receive

some funding. Here is what he emailed us this

morning.

“Truly time sensitive as OSHA input is critical

and due, summarized, by this Thursday...hence

request for input by end of day tomorrow.

Can you please assist in getting the word out to

the elastomeric mask fabricator community?

Dave (Dave Rousse of INDA) already has the

nonwoven fabric industry covered so this focus

is exclusively the elastomeric higher level

assembly fabricators.

·

Summary: (see below)

·

Deadline: Wednesday, Feb 10th

·

Critical window of opportunity (this week) to

secure OSHA “incorporation by reference” of the

ASTM Face Covering Standard.

·

Advisory Panel Developing Assessment of US

Capacity (Filter and Conversion) which will be

provided to OSHA. OSHA cannot implement an

Emergency Standard if there is inadequate supply

or if the supply is limited to a few vendors.

He requested the following

information.

-

What is their current monthly

production, in million (m/m);

-

What is estimated monthly

production by May 15, 2021; and

-

What could their monthly

production be by May 15, 2021

with government funding.

-

If possible, estimate order of

magnitude of needed funding as

we will attempt to facilitate

Title III funding support.

Title: URGENT: OSHA Mar 15 Emergency Standard /

Quality Masks / ASTM Face Covering Standard

Objective:

·

Develop support within Biden Administration and

CDC

·

Address misunderstandings around ASTM Standard,

supply, breathability, and fit.

Summary:

President Biden has issued an

Executive Order

directing OSHA to consider whether any emergency

temporary standards on COVID-19, including with

respect to masks in the workplace, are

necessary, and if such standards are determined

to be necessary, issue them by March 15, 2021.

Face coverings are a topic of concern,

particularly given the recent public debate

around double masking and overall mask quality

and fit.

OSHA is likely to either recommend

adherence to current CDC guidance (two or more

layers and covering the mouth and nose) OR it

could require face coverings made to the ASTM

Barrier Face Covering Standard.

If OSHA requires face coverings to meet

the ASTM Standard, it could also require minimum

specifications for tests included in the

standard, such as::

·

Minimum Filtration Level “X”

·

Minimum Breathability “Y”

·

Minimum Fit “Z”

To secure support within OSHA, the CDC, and

Biden’s Administration for the widespread

adoption of the ASTM standard in order to

improve the protective value of face coverings,

we need all parties to assist in mustering

political support, and in correcting

misunderstandings which are prevalent in the

public conversation.

(NOTE: As ASTM approaches release of the

standard,

a panel has been convened of recognized

Aerosol Transmission Experts in conjunction with

the Nonwovens industry (makers of the filtration

media) to make recommendations on the specific

performance levels that will ensure both the

highest protection value and a robust

marketplace capable of providing a adequate and

reliable supply of ASTM compliant face

coverings.

Misunderstandings to Correct:

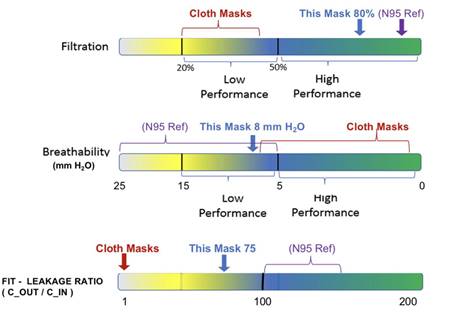

ASTM Standard is Either 20% or 50% Filtration:

This is inaccurate. The standard requires actual

filtration test results be submitted. In an

attempt to simplify public understanding, two

ranges are identified, 20%-50% (Level 1) and

50%-100% (Level 2). It is true that minimum

labeling requirements only mandate indication of

which range a given mask meets, however,

numerous example labels in the Appendix

illustrate clear identification of the exact

performance level (i.e. 80%). To address this

unfortunate construct, OSHA and CDC will need to

stipulate exact performance levels and any mask

vendor will be compelled to indicate the exact

performance level achieved. Here is a label that

meets the minimum labeling standard and also

provides performance levels against the key

benchmarks (N95, Cloth, and Surgical Style)

(NOTE: Suggestion to indicate Surgical Style at

40% filtration & leakage)

Adequate Filter Media Supply beyond Frontline

Responders:

While the US has rapidly increased fine fiber

meltblown nonwoven capacity (e.g., N95 capable)

to meet medical frontline responder needs, there

is inadequate supply of this high performing

filter material to meet the needs of the

extended worker community and general public.

However, there does exist adequate capacity to

deliver filtration that approaches that of the

N95 to serve the entire extended worker

community and general public without affecting

supply to medical frontline responders. There

are three sources of materials for the extended

worker and general public scope:

·

Excess Meltblown N95 material

·

New Materials (i.e. NC State Nonwoven Institute

Spunbond Material)

being developed

·

Extensive Capacity of Other Nonwoven Materials

That Approach N95 Performance.

Rapid Production Capacity:

·

Elastomeric Mask Housings:

While disposable US N95 conversion equipment is

constrained (cost and lead time), by emphasizing

elastomeric designs which can readily be scaled

up by duplicating existing injection molding

tooling ($20K-$100K / tool) and engaging the

extensive injection molding machines within the

US, supply is unconstrained.

·

Flat Filters:

While formed disposable mask fabrication is

highly constrained, flat filter fabrication can

readily be accomplished with existing nonwoven

equipment lines (i.e. from the upholstery

industry). Flat layers are assembled, welded,

and cut to shape. The welding / cutting tools

can be replicated for $100K. It is worth noting

that flat filters in elastomeric masks tend to

use less material and last longer in comparison

to disposable N95 respirators.

·

Pleated Surgical Style “Non-medical” Masks:

At the beginning of the pandemic, the US had ~

12 companies producing disposable formed N95

respirator masks. In response to the crisis,

approximately 24 companies entered the market

yet elected to setup factories to produce the

surgical style pleated face coverings. There is

adequate US capacity to immediately supply both

the extended worker and general public demand.

While pleated surgical style masks are normally

for splash protection, and do not make an

effective seal (~ 40% effective particle

filtration), many models are actually made with

filtration material that can achieve very high

levels (~ 95%) if they are sealed to the face

using a secondary elastomeric harness such as

the “Fix the Mask” brace.

·

Surgical Mask “Fix the Mask” Brace:

This simple solution is made of medical grade

silicone using compression molding.

·

Fit & Breathability:

The ASTM standard was deliberately developed to

improve breathability. Recognizing that workers

and the public may wear such protection for the

entire workday, the breathability performance

criteria, in millimeters of H2O of pressure

resistance, was set at a challenging level of 5

mmH20 or less.

In actuality, a comfortable range is 5-10

mm H20.

Reply to Couch Request

QUANTITY AND COST OF MASKS NEEDED The majority

of N95 and surgical masks are being supplied to

3% of the population (10 million people) whose

mask use in three times greater than

the next

more active group and 15 times greater than the

majority of people inhabiting public space. This

ratio is a function of viral load and numbers of

hours

of exposure to that load. this can be

considered as “relative mask duty”. One extreme

is the nurse in an isolation ward. At the other

is the individual who is only in public space

when at the store. This present group of 10

million can be labeled as the “present target”

Some masks are designed to be reusable for up to

30 days without filter inserts. Others are

designed to last even longer periods with

periodic filter inserts. Some filters with long

life cost more than $30.

However the cost per daily use can be

less than $1. In contrast someone may be wearing

several surgical masks per day.

|

Number of

People -

millions |

Mask Ratio |

Number of masks

in equivalent

period |

% |

|

10 |

15 |

150 |

24 |

|

50 |

5 |

250 |

39 |

|

240 |

1 |

240 |

37 |

|

30 |

0 |

0 |

0 |

|

330 |

640 |

100 |

Approximately three times as much relative mask

duty will be needed for the public as presently

needed by the present target (medical workers,

first responders, and those with industrial

exposure).

If this mask duty is primarily supplied by

surgical masks with braces it is possible that

the public numerical requirements will be three

times those of the present N95/surgical mask

users.

On the other end of the spectrum where the

relative mask duty is supplied by reusable masks

which last 10 times longer per unit of relative

duty, then the public mask numerical needs are

only 30 % of those of the present target.

So in terms of numbers we are talking about a

range for the public of 0.3 to three times the

present target. However in terms of material

consumption there is more media and other

components in the reusable masks. So the amount

of material will range from one to three times.

The cost per unit of relative mask duty

will be similar. So fitting the public with

effective masks will cost three times what is

being spent on the present target.

RATE AT WHICH PRODUCTION CAN BE INCREASED

Media availability is a limiting factor

on production increase.

However, some mask suppliers such as

Vogmask have designed their masks so that

meltblowns are just one of many layers. The

result is that the meltblown layer is better

protected and lasts longer.

Other mask makers use materials other than

meltblown media. There is no shortage of media

if

limits on resistance are nor too strict. The

amount of filterable media can be varied.

Resistance varies as the square of velocity. So

a slight increase in available media reduces

mask resistance.

As long as cloth masks are allowed in public

space, there is little incentive for rapid

expansion of tight fitting efficient masks. As

soon as this changes and the demand is clear,

there could be rapid expansion. It is also

likely that some of the large companies

supplying cloth masks could switch to making

tight fitting efficient masks. So we are not

talking about increases in numbers of masks as

much as we are increases in the number of

effective masks.

THE IMPACT OF GOVERNMENT SUBSIDIES Expenditures

by the government are best delivered as coupons

and not vouchers for masks or for purchase and

delivery of free masks. The reason is that the

choice may be a 30 dollar mask rather than one

for 2 dollars. If a number of coupons are

provided they could be used on one or multiple

masks.

With the coupons the market for the masks is

increased and in effect assured. If the coupons

can only be used for effective masks, the mask

suppliers will be willing to spend the money to

expand.

Capabilities of U.S. Mask Makers to Expand

Production

Respirator suppliers also have public mask

versions. MSA, 3M and Honeywell all have

public mask versions.

Armbrust American

is capable of gearing up to manufacture billions

of masks and now even has its own meltblown

media manufacturing. The company has been adept

at buying equipment and moving to production

very quickly. Many articles about the company

appear in the Alert. There is also a recorded

interview.

TAIJI Medical Supplies Single-Use Face Masks

Designed to be Protective and Comfortable

TMS occupies a 120,000 sq ft facility in

Lincolnton, NC that is already producing

volumes of masks and will scale to millions.

Masks can be made for nearly the same price as

those made in China. TMS believes America should

not have to choose between quality and price in

a time of need.

TMS has two (2) melt-blown fabric machines

in-house. Melt-blown fabric is the center layer

of each mask and is what provides filtration.

Many manufacturers were hindered during the

height of the pandemic as they rely on sourcing

from overseas.

The company says it has combined automation,

vertical integration and American ingenuity to

solve the problem

Medical-grade surgical and protective face masks

are designed, developed and produced end-to-end

in America (Lincolnton, NC).

Twenty

fully-automated assembly lines can produce

thousands of masks per minute.

The vertically integrated factory takes raw

polypropylene and transforms it into surgical

and protective face masks in seconds.

Cummins and Dupont are Working Together to Help

Address the Current Shortage of N95 Masks

According to Amy Davis, Vice President of

Cummins Filtration, with many of the world’s

leading mask manufacturers in need of the

critical materials to assemble the masks

and struggling to meet demand, Cummins will

use pre-existing filter technology in

partnership with DuPont to help fill the supply

void.

"Cummins is re-evaluating our supply base and

manufacturing capabilities to identify how we

can support our healthcare professionals who

rely on critical personal protective equipment

to do their jobs," Davis said. "Our NanoNet®

Media can fill a key supply void and help

address the mask shortage facing the United

States and other countries around the world."

The project also aims to provide open source

instructions that other healthcare systems and

groups can use to create their own respirator

masks.

Cummins’ NanoNet® and NanoForce® Media

technology, which uses DuPont’s Hybrid Membrane

Technology (HMT), can typically be found in air,

fuel and lube filtration products used in

heavy-duty diesel engines to prevent long-term

engine wear, but also can be used in the N95

respirator masks worn by healthcare

professionals to filter harmful airborne

particles that can spread COVID-19.

Vogmask is a U.S. based supplier with expandable

supply capability.

Vogmask has spent nine years to achieve maximum

comfort, attractiveness, tight fit and

efficiency of its masks. There are many articles

on Vogmask in the alerts and presentations in

the McIlvaine webinars.

NXT Nano can Ramp Up to Meet Future Demand

Quickly.

These are excerpts from the McIlvaine interview

with Andy McDowell of NXT Nano

1. How fast can they ramp up production of

high efficiency media?

2. How flexible is a line to make mask,

HVAC, microfiltration, or other media?

3. How much time does it take to change a

line over to make a different product?

We talked to Andy McDowell, director sales and

marketing at NXTNano of Nano. In the Alert we

covered their mask making activities and also

the extent of the use of their media for gas

turbine intake filters, HVAC, masks and

microfiltration.

Andy gave some very useful answers to our

questions.

Bob: Andy how long does it take to build a new

line?

Andy: Only 3 to 4 months and since we have to

install humidity control and other basic

services it is even easier to install multiple

lines rather than just one.

Bob: Can you give us some idea of the

production of one line?

Andy: If we are making masks and working 24-7

it is 86,000 m2/day. If we are making HVAC

media it is about 30% more.

Bob: How many masks can be produced per m2?

Andy: About 40 surgical grade masks or 30 N95

grade masks.

Bob: How many HVAC filters can be produced per

m2?

Andy: It varies but a rule of thumb would be 1

filter/m2.

Bob: How much time does it take to change over

from one product to another?

Andy: We can make the change from one product

to another in a matter of minutes not hours.

Bob: We see a big opportunity for the

filtration industry to take a positive rather

than negative attitude and say we can invest in

the production equipment necessary to see that

everyone can be protected by wearing high

efficiency masks and spending time in space that

is filtered to remove viruses. Do you think

your company is capable of making major

expansions?

Andy: We just expanded capacity and do not

see major obstacles in expanding as warranted.