CATER Mask

Decisions

January 4, 2021

Vaccines are not a Short Term Solution so We

Need the Safe Bubble Initiative

New Methods are Needed

to Assure a Tight Fit on Every Mask Worn

in Public

Suppliers of Disposable Masks are Focused on

Increasing Production and Not Necessarily

Holistic Solutions

Important New Findings on Performance

Differences Between Masks

N95 Tested at 98% FFE

_____________________________________________________________________________

Vaccines are not a Short Term Solution so We

Need the Safe Bubble Initiative

There are many reasons why we will need to

depend on HVAC and masks as part of a Safe

Bubble Initiative (SBI) for at least several

years.

·

Hundreds of thousands of wealthy citizens of the

world will die in the next 12 months without the

SBI.

·

Millions of poorer citizens will die in the next

4 years without SBI.

·

Major impact of the vaccines will not be felt in

wealthy countries until late in the year and not

for years in poorer countries.

·

New variants of the virus are eventually likely

to evolve into one which resists the present

vaccines.

·

Prevention of future pandemics along with

efforts to reduce the impact of air pollution,

wildfires, and influenza will provide long

lasting benefits.

New Methods are Needed

to Assure a Tight Fit on Every Mask Worn

in Public

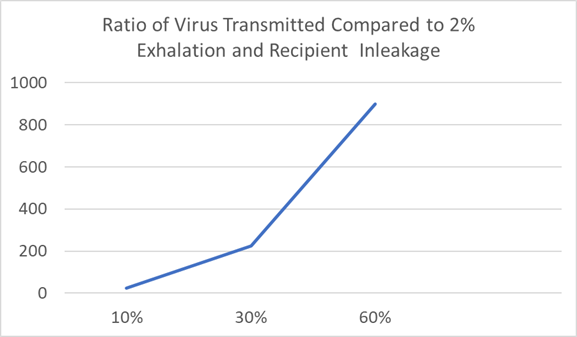

Mask leakage can vary from 2 to 60%.

The differences in virus transmission

are huge when you include both emitter

and recipient. At 2% escaping from the

transmitter only 2 x .02 or .04%

of the

air leaks into the recipient mask. With the 60%

leakage 36%

can be inhaled by the recipient. So 36/04

or 900 times more virus is inhaled with the

looser masks.

When you combine air leakage and media

efficiency for both transmitter and recipient

the same high ratios are found. However, other

measures such as limiting capacity are less

effective and hugely costly to the economy. You

can require a school to operate at 10% capacity

but that only provides a 10 to 1

reduction ratio.

With the Safe Bubble Initiative every entrant to

a facility would be checked to assure that his

mask is tight fitting and efficient. There would

be a tiered approach.

· Tier One: Every mask type and size would be tested by the manufacturer under various motions and with individuals whose facial features match the mask size. Quantitative fit testing would be used. An approved fit testing laboratory would conduct these tests and provide the rating. The entrant to a facility would only have to show that he is wearing a rated mask and has chosen a proper size.

·

Tier One Alternative: Local operators such as

Fitness Centers or Department Stores could sell

masks and provide fit testing for each

purchaser. If they are selling one brand of mask

with five sizes, they select the appropriate

size for the purchaser and run the two minute

fit test.

·

Tier Two: Each entrant would be checked to see

that he has an accredited mask and that it is

being worn properly. This inspection could

include something as elaborate as periodic

qualitative testing or just visual inspection.

One or more visual methods need to be created. A

visual check can determine if the mask has the

following attributes:

·

Stays in position on face across a variety of

motions: walk, talk, bend over, head side to

side

·

Does not restrict field of vision

·

Adjustable noseband to seal gaps on either side

of nosebridge-mandatory

·

Head strap accessory for alternate attachment

with adjustable tension in back of head-optional

·

Trim or other design element to create a seal

between user's face and mask-optional

The manufacturer also should supply

·

Correct donning, doffing, and noseband

instructions

·

Product support to ensure correct size

·

Offer in several sizes to fit a wide range of

facial shapes and structures

·

Practical performance testing on test subjects

to determine leakage under normal activities (on

sample test subjects in lab setting)

A manual check can also be provided. Here is the

procedure recommended by Vogmask.

“Place your fingers

on the cheekbones and thumbs on sides of

chin to do inhale and exhale fitting check.

"Inhale slowly. Check to see if the facepiece

suctions slightly towards your face. No air

should leak in between your face and mask.

-

Exhale slowly. The facepiece

should be bulging slightly

outwards as exhale exits back

through facepiece.

-

Check again for leaks between

your face and the facepiece of

the respirator.

-

If you detect any leaks,

readjust the ear loops or head

straps and check again for fit.

-

If you cannot get a good seal

around nose and mouth, the mask

is not correct size and we

request you contact us.”

Additional ways to check the fit could be

developed.

Some creativity is needed. Here is one

idea.

Instead of lighting up a pumpkin why not use a

cheap disposable light to light up the openings

in the mask.

the subject would place the light in his

mask. He could manipulate it through the soft

fabric or with attached threads and change the

trajectory of the light beam to check the

periphery

while the inspector is watching.

Lights for lanterns are 30 cents each on Amazon.

So they could be given to the entrant after use.

Variations of qualitative testing could be

performed. A test only requires a hood and

method of injecting a sweet or bitter aerosol.

Many facilities have

some sort of

a line where temperature is checked.

They could be utilized with a walk

through unit. A fan filter unit and walk in

module would cost less than $5k.

Each entrant could be tested with a

modified taste test.

These are just a few approaches. There could be

much better ones if only a little time is spent

devising them. When you consider that the mask

fit is as important as vaccines and more

important than social distancing it is important

to measure it and act accordingly.

Suppliers of Disposable Masks are Focused on

Increasing Production and Not Necessarily

Holistic Solutions

The huge production requirements based on

multiple mask use per day for healthcare workers

will hamper efforts to supply enough masks and

filter media to properly address COVID.

Therefore reusable masks are a critical

necessity.

3M

replied to the McIlvaine proposed

Safe Bubble Initiative by pointing out

that all their resources are needed to make

disposable masks for healthcare workers. At the

very least there should be an effort to see how

many times disposable N95 masks can be worn by

the public before the fit and efficiency

deteriorate. Many of the two billion masks 3M

hopes to make will be needed for

applications where a disposable mask is

most appropriate. When a nurse is entering a

COVID ICU unit and then may be entering the room

of a cancer patient the risk of transmission

from one patient to another is too high to

consider wearing a previously used and

sterilized mask.

But the average individual who has probably not

been exposed to COVID during the day can wear

his mask multiple times. The N95 mask can have a

high net efficiency and even with some

deterioration will

be many times more effective than the

typical cloth

mask.

The 3M position is understandable. They are to

be commended for the great effort they have made

to increase production. It may turn out that

there really is a need for the two billion masks

they make to be used by medical personnel. If

four masks are required each day then this is

only enough for 500 million mask days or 1.7

million people for 300 days.

Here is

the 3M reply.

Thank you for your inquiry. 3M is committed to

supporting public health and the government

response to the COVID-19 outbreak. While 3M

appreciates offers to collaborate, we are unable

to commit resources to review your new product

idea at this time. Since the outbreak of

COVID-19, we have increased our production of

personal protective equipment, and we are

working to nearly double our production of

respirators, to

almost 2 billion globally, within the next 12

months. A diversion of resources would

reduce our ability to maximize production of

critical supplies and therefore reduce our

ability to have the greatest public health

impact possible.

While we are unable to work together at this

time, we may be interested in a potential

collaboration in the future when our production

schedules are back to normal volume. You are

welcome to submit your unsolicited,

non-confidential idea at

https://www.3m.com/3M/en_US/company-us/unsolicited-idea-submission-policy/.

That link will provide guidelines for 3M

acceptance of unsolicited ideas. As a reminder,

you are free to submit your ideas to other

companies.

Thank you for your understanding as we work to

deliver high volume production in the short to

medium term. We are grateful for your

commitment to public safety during the rapidly

changing COVID-19 outbreak and are amazed by the

number of people and companies willing to come

together to help protect our healthcare workers

on the front lines of this fight.

Important New Findings on Performance

Differences Between Masks

A new study for CDC confirms many past studies.

Tight fitting and efficient masks

perform much better than the average

public mask. An abstract and summary is provided

below along with a link to the full article.

The article provides

Evaluation of Cloth Masks and Modified Procedure

Masks as Personal Protective Equipment for the

Public During the COVID-19 Pandemic

Phillip W. Clapp, PhD1,2; Emily

E. Sickbert-Bennett, PhD, MS3; James

M. Samet, PhD, MPH4; et

alJon Berntsen, PhD5; Kirby

L. Zeman, PhD2; Deverick

J. Anderson, MD, MPH6; David

J. Weber, MD, MPH3,7; William

D. Bennett, PhD2,7; for

the US Centers for Disease Control and

Prevention Epicenters Program

Key Points

Question: What

are the fitted filtration efficiencies (FFEs) of

consumer-grade masks, improvised face coverings,

and modified procedure masks commonly used

during the coronavirus disease 2019 (COVID-19)

pandemic?

Findings: In

this comparative study of face covering FFEs, we

observed that consumer-grade masks and

improvised face coverings varied widely, ranging

from 26.5% to 79.0% FFE. Modifications intended

to enhance the fit of medical procedure masks

improved FFE measurements from 38.5% (unmodified

mask) to as much as 80.2%.

Meaning:

Simple modifications can improve the fit and

filtration efficiency of medical procedure

masks; however, the practical effectiveness of

consumer-grade masks available to the public is,

in many cases, comparable with or better than

their non-N95 respirator medical mask

counterparts.

Abstract

Importance:

During the coronavirus disease 2019 (COVID-19)

pandemic, the general public has been advised to

wear masks or improvised face coverings to limit

transmission of severe acute respiratory

syndrome coronavirus 2 (SARS-CoV-2). However,

there has been considerable confusion and

disagreement regarding the degree to which masks

protect the wearer from airborne particles.

Objectives:

To evaluate the fitted filtration efficiency

(FFE) of various consumer-grade and improvised

face masks, as well as several popular

modifications of medical procedure masks that

are intended to improve mask fit or comfort.

Design, Setting, and Participants:

For this study conducted in a research

laboratory between June and August 2020, 7

consumer-grade masks and 5 medical procedure

mask modifications were fitted on an adult male

volunteer, and FFE measurements were collected

during a series of repeated movements of the

torso, head, and facial muscles as outlined by

the US Occupational Safety and Health

Administration Quantitative Fit Testing

Protocol. The consumer-grade masks tested

included (1) a 2-layer woven nylon mask with ear

loops that was tested with an optional aluminum

nose bridge and nonwoven filter insert in place,

(2) a cotton bandana folded diagonally once

(i.e., “bandit” style) or in a (3) multilayer

rectangle according to the instructions

presented by the US Surgeon General, (4) a

single-layer woven polyester/nylon mask with

ties, (5) a nonwoven polypropylene mask with

fixed ear loops, (6) a single-layer woven

polyester gaiter/neck cover balaclava bandana,

and (7) a 3-layer woven cotton mask with ear

loops. Medical procedure mask modifications

included (1) tying the mask’s ear loops and

tucking in the side pleats, (2) fastening ear

loops behind the head with 3-dimensional–printed

ear guards, (3) fastening ear loops behind the

head with a claw-type hair clip, (4) enhancing

the mask/face seal with rubber bands over the

mask, and (5) enhancing the mask/face seal with

a band of nylon hosiery over the fitted mask.

Main Outcomes and Measures: The

primary study outcome was the measured FFE of

common consumer-grade and improvised face masks,

as well as several popular modifications of

medical procedure masks.

Results: The

mean (SD) FFE of consumer grade masks tested on

1 adult male with no beard ranged from 79.0%

(4.3%) to 26.5% (10.5%), with the 2-layer woven

nylon mask having the highest FFE. Unmodified

medical procedure masks with ear loops had a

mean (SD) FFE of 38.5% (11.2%). All

modifications evaluated in this study increased

procedure mask FFE (range [SD], 60.3% [11.1%] to

80.2% [3.1%]), with a nylon hosiery sleeve

placed over the procedure mask producing the

greatest improvement.

Conclusions and Relevance: While

modifications to improve medical procedure mask

fit can enhance the filtering capability and

reduce inhalation of airborne particles, this

study demonstrates that the FFEs of

consumer-grade masks available to the public

are, in many cases, nearly equivalent to or

better than their non-N95 respirator medical

mask counterparts.

Introduction

Severe acute respiratory syndrome coronavirus 2

(SARS-CoV-2), the cause of coronavirus disease

2019 (COVID-19), is a transmissible virus that

infects the upper and lower respiratory tract,

leading to a high viral titer in saliva and

respiratory secretions. A key public health

control strategy for mitigating SARS-CoV-2

transmission is use of masks or face coverings

by the public. Masks that completely cover the

nose and mouth are effective at reducing

seasonal coronavirus and influenza transmission

when worn by infected persons and noninfected

persons who may come into contact with infected

individuals. This is supported by emerging

epidemiologic data that indicate that

community-wide use of masks can effectively

contribute to the prevention of SARS-CoV-2

transmission.

As the adoption of face coverings during the

COVID-19 pandemic becomes commonplace, there has

been a rapid expansion in the public use of

commercial, homemade, and improvised masks that

vary considerably in design, material, and

construction. Similarly, the press and social

media outlets have reported on numerous

innovative “hacks,” devices, and modifications

(enhancements) that claim to improve the

performance characteristics of conventional

masks (typically surgical or procedure masks).

Despite their widespread dissemination and use

during the pandemic, there have been few

evaluations of the efficiency of these face

coverings or mask enhancements at filtering

airborne particles. In this study, we used a

recently described methodological approach based

on the Occupational Safety and Health

Administration (OSHA) Fit Test to determine the

fitted filtration efficiency (FFE) of various

consumer-grade and improvised face masks, as

well as several popular modifications of medical

procedure masks.

Methods

Testing Procedure

Fitted filtration efficiency tests were

conducted between June and August 2020 in a

custom-built exposure chamber (US Environmental

Protection Agency Human Studies Facility in

Chapel Hill, North Carolina) as recently

described. The institutional review board at the

University of North Carolina at Chapel Hill

waived the need for study approval as well as

individual consent needed for device testing.

Briefly, a TSI 8026 Particle Generator was used

to supplement the chamber with sodium chloride (NaCl)

particles that had a count median diameter of

0.05 μm (range, 0.02-0.60 μm) as measured by a

scanning mobility particle sizer. The test

atmosphere was allowed to stabilize for 30

minutes before FFE testing. The chamber

temperature and humidity during testing ranged

from 73.4 °F to 85.1 °C and 10% to 50%,

respectively. The test atmosphere used for this

study reflects typical indoor conditions, with

exposure to small particles that are slightly

smaller than individual SARS-CoV-2 virions

(reported to range between 0.06 μm and 0.14 μm).

A sampling port was installed in each mask using

a TSI model 8025-N95 Fit Test Probe Kit to allow

sampling behind the mask. All masks were fitted

on a man (weight, 165.3 lb; height, 5 ft and

10.1 in; head size, 23.0 in) with no beard. A

pair of TSI 3775 Condensation Particle Counters

were run in single-particle analysis mode to

continuously monitor ambient particles (0.02

μm-3 μm) in the chamber just outside the face

mask and particles in the breathing space behind

the face mask at a sampling rate of 1 second.

Fitted filtration efficiency measurements were

collected during a series of repeated movements

of the torso, head, and facial muscles as

outlined by the OSHA Quantitative Fit Testing

Protocol (Modified Ambient Aerosol CNC

Quantitative Fit Testing Protocol For Filtering

Facepiece Table A–2—RESPIRATORS). The FFE

corresponds to the concentration of particles

behind the mask expressed as a percentage of the

particle concentration in the chamber air and

was measured for the duration of each test

described in the OSHA protocol (bending at the

waist, reading aloud, looking left and right,

and looking up and down). The overall percentage

of FFE is calculated as 100 × (1 − behind the

mask particle concentration / ambient particle

concentration), and the percentage of FFE and

the standard deviation were calculated across

the length of the test. The total testing time

for each mask was approximately 3 minutes.

Products Tested

Two categories of products were tested for this

study: consumer-grade face masks and medical

procedure masks with and without enhancements.

The following consumer-grade masks were tested:

(1) a 2-layer woven nylon mask (54% recycled

nylon, 43% nylon, 3% spandex) with ear loops

(Easy Masks LLC) tested with an optional

aluminum nose bridge and nonwoven filter insert

in place, (2) a cotton bandana folded diagonally

once “bandit” style or in a multilayer rectangle

according to the instructions presented by the

US Surgeon General

https://www.cdc.gov/coronavirus/2019-ncov/prevent-getting-sick/how-to-make-cloth-face-covering.html),

(3) a single-layer woven polyester/nylon mask

(80% polyester, 17% nylon, 3% spandex) with ties

(Renfro Corporation) (4) a nonwoven

polypropylene mask with fixed ear loops (Red

Devil Inc), (5) a single-layer woven gaiter/neck

cover balaclava bandana (92% polyester and 8%

spandex; MPUSA LLC), and (6) a 3-layer woven

cotton mask (100% cotton) with ear loops (Hanesbrands

Inc).

The baseline FFE of unmodified medical procedure

masks with elastic ear loops (Cardinal Health

Inc) was measured (n = 4) and compared with the

FFE of the same type of mask with various

modifications designed to enhance its function.

The following modifications were tested: (1)

enhancing the mask/face seal by tying the ear

loops and tucking in the side pleats; https://youtu.be/UANi8Cc71A0),

(2) fastening ear loops behind the head with

3-dimensional–printed ear guards; https://www.thingiverse.com/thing:4249113),

(3) fastening ear loops behind the head with a

23-mm claw-type hair clip, (4) enhancing the

mask/face seal by placing a ring of 3 ganged

rubber bands over the mask, with the center

rubber band placed over the nose and chin of the

participant and the left and right side bands

looped over each ear; “fix-the-mask” 3–rubber

band method https://www.youtube.com/watch?v=CVjGCPfRwUo),

and (5) enhancing the mask/face seal by sliding

a 10-inch segment of nylon hosiery over the

fitted mask.

Results

This study evaluated the FFE of 7 consumer-grade

masks and five procedure mask modifications. The

mean (SD) FFE of consumer-grade face masks

tested in this study ranged from 79.0% (4.3%) to

26.5% (10.5%), with the washed, 2-layer woven

nylon mask having the highest FFE and the

3-layer woven cotton mask having the lowest. The

cotton bandana folded into a multilayer

rectangle affixed to the ears with rubber bands,

as described by the US Surgeon General, provided

a mean (SD) FFE of 49.9% (5.8%). Folding the

bandana bandit style produced a similar result

(mean [SD] FFE, 49.0% [6.2%]). The tested mean

(SD) FFE of the single-layer woven polyester

gaiter/neck cover balaclava bandana was 37.8%

(5.2%). The single-layer woven polyester/nylon

mask, which is attached with tie strings, tested

at a mean (SD) FFE of 39.3% (7.2%). The nonwoven

polypropylene mask with nonelastic (fixed) ear

loops tested at a mean (SD) FFE of 28.6%

(13.9%).

As expected based on data from our previous

work, a National Institute for Occupational

Safety and Health–approved 3M 9210 N95

respirator used as a reference control provided

very high mean FFE (98.4% [0.5%]; n = 1). The

medical procedure masks with elastic ear loops

tested in this study had a mean (SD) FFE of

38.5% (11.2%), (which was lower than that of

medical surgical masks with tie strings (71.5%

[5.5%]; n = 4). Tying the ear loops and tucking

in the corners of the procedure mask to minimize

gaps in the sides of the mask increased the mean

(SD) FFE to 60.3% (11.1%). The “fix-the-mask”

3–rubber band modification and the nylon hosiery

sleeve modifications, which were also intended

to reduce gaps between the mask and the wearer’s

face, improved mean (SD) FFE to 78.2% (3.3%) and

80.2% (3.1%), respectively.

Modifications to improve the seal of the mask

against the face by increasing the tension of

the ear loops also improved FFE. Attaching the

ear loops to the ear guards device using the

center hooks (tightest option) increased

procedure mask mean (SD) FFE to 61.7% (6.5%).

Similarly, joining the ear loops behind the

wearer’s head using a claw-style hair clip

increased the procedure mask mean (SD) FFE to

64.8% (5.1%). None of the modifications tested

enhanced procedure mask FFE to the level of an

N95 respirator.

Discussion

In this study, consumer-grade masks and medical

procedure mask modifications were tested as

personal protective equipment (protection for

the wearer) against a test aerosol of 0.05-μm

NaCl particles. Although the FFE of

consumer-grade masks and face coverings was

variable, the FFE of some consumer-grade

products exceeded that of medical-grade

procedure masks. For example, the 2-layer woven

nylon mask with ear loops was tested under

various conditions, including with and without

an aluminum nose bridge, with and without a

commercially available nonwoven insert, and

after 1 wash cycle in a standard household

washing machine (air-dried on a drying rack).

The unwashed nylon mask without a nose bridge or

insert had an FFE of 44.7%. The addition of a

nose bridge reduced visible gaps around the nose

and increased FFE to 56.3%. Adding a nonwoven

filter insert to the mask with the nose bridge

in place resulted in a further increase in FFE

to 74.4%. Interestingly, the FFE of the nylon

mask (with the nose bridge but without the

filter insert) improved slightly to 79.0% after

washing. It is unclear why washing alone

improved the FFE from 56.3% to 79.0%. It may be

that the washing/drying process unraveled some

of the fibers to increase the overall filtration

surface, and thus filtration efficiency, of the

medium, or perhaps it modified the mask shape or

size in a way that improved fit, or both. The

washing/drying test was not repeated with

additional nylon masks. Further investigation to

assess the association of single and multiple

washing with mask integrity and material

disposition would be necessary to validate any

improvement in FFE.

The woven cotton mask, which comprises 3 layers

and has a thin, flexible metal nose bridge, had

the lowest FFE in this study (26.5%). The

relatively loose weave of the cotton layers,

while providing improved breathability and

comfort, may reduce filtration efficiency.

Additionally, we evaluated the FFE of improvised

face coverings, including a standard cotton

bandana and a neck gaiter balaclava bandana. The

cotton bandana, when folded either bandit style

or according to the US Surgeon General’s

instructions, achieved approximately 50% FFE,

which is better than the ear loop procedure mask

we tested. Neck gaiter balaclava bandanas have

also emerged as a popular face covering,

particularly among athletes and young adults. As

tested in this study, the single-layer gaiter,

which was made of 92% polyester and 8% spandex

and fits tightly to the wearer’s nose and mouth,

had an FFE of 37.8%. While this face covering

appeared to fit the wearer well, with no visible

gaps in the seal, it may be that the relatively

low FFE can be attributed to the low filtering

efficiency of a single thin layer of woven

material with large porosity.

For medical procedure masks, modifications that

enhanced the fit between the mask and the

wearer’s face improved FFE. Simply tying the ear

loops and tucking the corners of the mask

against the wearer’s cheeks visibly improved

mask fit and increased FFE from 38.5% to 60.3%.

The most effective modification tested was the

use of a nylon hosiery sleeve placed over the

procedure mask. This modification, which held

the mask tight to the wearer’s face, eliminated

all visible gaps and increased FFE from 38.5% to

80.2%. However, donning the nylon sleeve over

the procedure mask was cumbersome and limited

the wearer’s ability to adjust the procedure

mask. Generally, improvements in procedure mask

FFE appeared to be associated with the integrity

of the seal of the edges of the mask to the

wearer’s face, demonstrating the importance of

mask fit to maximizing filtration. While all of

the modifications described enhanced protection

against airborne particles for the wearer, not

all were comfortable or practical for extended

use. For example, the 3–rubber band

“fix-the-mask” modification created considerable

pressure on the wearer’s ears, making it

uncomfortable after only minutes of wear and

raising questions about its adoption by the

general public. While the modifications shown in

this article can improve mask fit and provide

increased filtration of airborne particles, it

is important to choose a modification in which

discomfort is not a deterrent from wearing the

mask for prolonged periods.

The full text is included in the link below to

an article in the Journal of the American

Medical Association.

N95 Tested at 98% FFE

3M™

says its Aura™ Series Particulate Respirator

9210+, N95 is a breakthrough in comfort and

convenience. This three-panel, flat-fold

disposable respirator with its innovative design

helps provide comfortable, reliable worker

protection against non-oil based particles.

The lightweight, three-panel designed disposable

N95 particulate respirator helps provide

quality, reliable, and convenient worker

respiratory protection. 3M uses a variety of

innovative technologies and features to help

meet respiratory protection and comfort needs.

3M`s proprietary filter media, 3M™ Advanced

Electret Media, filters dust and other

particles, while allowing for easy breathing.

The soft inner material provides added comfort

while the soft nose foam and adjustable nose

clip help provide a custom seal. Braided

headbands provide comfort and help minimize

pulling of hair.

Unique features to the Aura™ Series Particulate

Respirators include sculpted nose panel that

follows the contours of the nose allowing more

room for eyewear, embossed top panel that is

designed to help reduce the fogging of eyewear

from warm, moist exhaled air, and innovative

chin tab designed for ease of positioning,

donning, and adjustment. These features are

designed to enhance user comfort and help

increase wearability. The unique three-panel

flat fold design is collapse resistant and its

individual packaging allows for easy storage

prior to use. Suggested applications: Grinding,

Sanding, Sweeping, Bagging and other dusty or

arid operations. Can also be used to help reduce

inhalation of certain airborne biological

particles like mold, Bacillus anthracis,

Mycobacterium tuberculosis, etc. Example

applications include emergency or pandemic

preparedness planning, stockpiling, etc.