CATER Mask

Decisions

December 22, 2020

CATER 95 Masks can

Save Many Lives in the Next Nine Months

Can Camfil be a

Producer of CATER 95 Masks to Meet the Huge

Need?

Armbrust American

Receives ASTM Level 3 Rating for Its Masks

New COVID Bill Includes Funds to Improve School

Ventilation

________________________________________________________________________

CATER 95 Masks can

Save Many Lives in the Next Nine Months

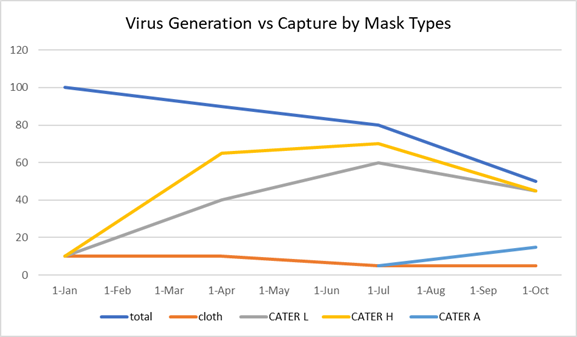

Vaccinations are likely to reduce virus

transmission by over

40% in the next nine months. But many

lives will still be lost. CATER masks can be a

big contributor to reducing these losses.

the impact will depend on how quickly

they can be made available. Two scenarios based

on a low and high estimate of how quickly

production can be increased are shown in the

graph.

In either case CATER 95 masks will save

hundreds of thousands of

lives which might otherwise be lost in

the period.

·

Total = virus

transmitted. This decreases as vaccinations take

effect

·

Cloth =

virus eliminated by inefficient loose

fitting masks

·

CATER L = virus

eliminated with minimum ramp up of CATER 95

production

·

CATER H = virus

eliminated with maximum ramp up of CATER 95

production

·

CATER A = increased

CATER 95 sales for air pollution, health and

wildfire protection

Under this scenario CATER masks make a big

contribution to COVID mitigation in the next

nine months. Suppliers then divert part of the

production to other air contamination reduction

needs. Total CATER mask production would be

modestly lower in the July-December period but

sales would steadily increase in 2022 to

meet the large non COVID needs.

Can Camfil be a Producer of CATER 95 Masks to

Meet the Huge Need?

Camfil seems to have the capability to quickly

make enough CATER 95 masks to help meet the

urgent needs McIlvaine projects for the next

nine months.

In March 2020, Camfil started helping the

healthcare community by manufacturing and

testing respiratory protection. The hospital

environment is one of the core competence areas

for Camfil. They have successfully delivered

filter and ventilation solutions to various

hospitals and care facilities around the globe

in the past many decades including operating

theaters, laboratories, reception rooms,

intensive care units, and pharmacies.

Camfil has delivered CamProtect respiratory

protection, primarily to the Stockholm Region

along with other institutions in the healthcare.

The product CamProtect is now CE-certified by

Force Certification A/S. Initial production was

100,000 masks per week.

The idea for a mask took shape within Camfil

when the corona outbreak first emerged. As

experts in air filtration solutions, ideas for

respiratory protection masks began to come in

from Camfil offices in Malaysia, Spain,

Slovakia, Sweden, and others. The project then

gained momentum through Camfil’s Global Tech

Center in Trosa, Sweden with other areas of the

Swedish organization. Since respiratory

protection is not part of Camfil’s regular

manufacturing output, Camfil kicked off a

large-scale internal initiative to get up and

running with a prototype. Experts from product

development, testing, materials, purchasing, and

production participated. The prototype was then

tested in one of

the laboratories.

Product development in the filter industry

usually takes several months or even years. For

this fast pace development, it took plenty of

hard work to redeploy production lines while

finding partners and suppliers who could help

make the idea a reality as soon as possible. The

production started in Trosa, Sweden, and

CamProtect respiratory protection masks became a

reality. That was the beginning of the product

CamProtect.

There is now a huge opportunity for CATER 95

masks. The question is whether Camfil has the

interest and capability to provide this reusable

type mask on the same accelerated basis that it

achieved with the disposable mask

Armbrust American Receives ASTM Level 3 Rating

for Its Masks

With the country still in dire need of personal

protective equipment during the pandemic, U.S.

manufacturing startup Armbrust American

announced that its entire line of disposable

surgical masks has received an ASTM Level 3

rating, the highest rating for filtration

effectiveness available in the world.

Additionally, the company has opened pre-orders

for N95 respirator masks, as well as implemented

updates to its surgical masks.

Armbrust American's Texas-based medical mask

production facility.

An alarming number of disposable face mask

products available to consumers do not actually

provide the level of filtration required to

protect against the novel coronavirus, which is

why having both ASTM Level 3 rating and being

FDA listed are so important. Obtaining a Level 3

rating means Armbrust American masks have passed

performance tests for fluid penetration,

bacterial filtration, flammability, blood

spatter filtration, and breathability. Testing

was performed by Nelson Laboratories LLC and

done in compliance with the FDA's Good

Laboratory Practices (GLP) regulations.

"The key difference between Armbrust

American masks and what you'll find on retail

shelves is a promise that you're buying the

safest surgical masks in the world," said

Founder and CEO Lloyd Armbrust. "You're also

buying from a trusted and reliable manufacturer

that's constantly making improvements to its

products, unlike established competitors who

have little financial incentive and don't sell

directly to American citizens like we do."

Six months after launching its first factory, Armbrust

American continues to demonstrate that

commitment to innovation. The latest example is

an upgrade to add a newly developed secure-fit

nose bridge to its surgical masks, allowing the

wearer to create a more secure seal around the

face. The company also recently activated its

first line of N95 Respirator masks, which are

now available for pre-order.

New COVID Bill Includes Funds to Improve School

Ventilation

The $900 billion COVID-19

stimulus deal approved by Congress

includes billions for elementary and secondary

schools, including dollars to help with

improving ventilation and air quality during the

pandemic.

A total of $54.3 billion has been secured for

the Elementary and Secondary School Emergency

Relief Fund. This will send formula funding to

states and school districts so they can respond

to the coronavirus crisis.

Those dollars can be used for school facilities

repairs and improvements, like heating,

ventilation, and air conditioning systems

projects to improve indoor air quality, as well

as addressing learning loss among students,

including low-income students, children with

disabilities, English learners, racial and

ethnic minorities, students experiencing

homelessness and children and youth in foster

care.

Like schools across the country, districts in Massachusetts have been working to improve HVAC systems so students can safely learn in classrooms. In Worcester, city officials continue to work on a $15 million project to upgrade both school and city air systems. Students in the district, which is the second-largest in Massachusetts, remain in remote learning.

In total, Worcester has as of last week received

more than $39 million in funding to address

COVID-19 in the community, according to city

documents. Of that funding, about $23 million

was provided for city use and $16 million is for

the Worcester Public Schools.

Though, those dollars do not include what

Worcester anticipates to receive through the

Federal Emergency Management Agency Public

Assistance Program. Funding through that program

does not have a limit on the total amount

Worcester is eligible to receive but will

provide 75% funding for eligible costs. The city

administration is working with a

Massachusetts-sponsored consultant to prepare

and submit eligible expenses for reimbursement.

So far, the city has incurred about $2.3 million

in expenses officials believe will be eligible

for reimbursement.

Worcester plans to complement FEMA PA funds with

the Coronavirus Relief Fund Municipal Program (CvRF-MP)

funding, through the Massachusetts Executive

Office of Administration and Finance, to provide

the required 25% match. Those CvRF-MP funds will

also be used for expenses related to COVID-19

that were accounted for in the annual budget and

that are not eligible under the FEMA PA. The

largest project in that category is the HVAC

upgrade project, according to city documents.

All expenses incurred before Dec. 30 for that

HVAC project will be applied to the CvRF-MP

grant, except for $1 million, which will be

funded through one of the Worcester Public

Schools grants, according to the documents.

Earlier this month, as the Northampton Public

Schools worked to transition from fully remote

to hybrid learning, officials said the district

had purchased 385 high-efficiency particulate

air (HEPA) air filters for classrooms and

installed more than a dozen MERV filters in

school HVAC systems. More

than $200,000 was spent to

upgrade the air filtration systems.

In the federal relief package, billions of

dollars are slated for other educational needs

beyond helping schools with facilities repairs

and improvements. In addition to the $600 direct

checks, which will arrive

to Americans within weeks,

the deal includes enhanced federal jobless

payments of $300 weekly until the spring,

hundreds of billions of dollars in small

business loans, and aid to health care

facilities as vaccines are distributed.