CATER Mask

Decisions

December 18, 2020

The Foundation of COVID

Mitigation Strategy Should be

Mask Effectiveness

Cummins is Making Masks with

Uniquely Charged Meltblowns

BelEmsa

Producing 200 Million

Masks per Month

H+V will

Expand

to 100

Million Mask Equivalents

per

Year

___________________________________________________________________________

The Foundation of COVID

Mitigation Strategy Should be

Mask Effectiveness

The strategy to defeat COVID

should be based on use of highly

efficient masks. All other

options are more costly and less

effective with the exception of

total lockdowns. The virus

spread with near normal activity

but correct use of CATER 95

masks will be less than if there

is a partial lockdown and use of

ASTM 20 masks.

The strategy which treats all

masks as equal makes little

sense. It is the equivalent of

saying that whether a room has

one occupant or 100 the risks

are the same. In fact if all

occupants are wearing CATER 95

masks the risk is equivalent to

the room with one unmasked

occupant. If every one of the

100 people is wearing

an ASTM 20 mask you have

the equivalent of 71 unmasked

people. This 70 to 1 ratio means

that mask efficiency should be

the cornerstone of COVID policy.

The following examples were

calculated based on available

information for various types of

masks. The net efficiency equals

the media efficiency less leaks.

|

Mask |

Efficiency % |

Leaks % |

Net Efficiency % |

|

CATER 99 |

99 |

-4 |

95 |

|

CATER 95 |

95 |

-4 |

91 |

|

CATER 93 |

93 |

-4 |

89 |

|

ASTM 50 |

50 |

-20 |

40 |

|

ASTM 20 |

20 |

-20 |

16 |

The leaks are derived from fit

testing and cannot be precisely

quantified in a given case. One

comprehensive set of tests with

a CATER 95 masks showed leakage

between 2 and 8 %. The actual

leakage depends on the face, the

mask dimensions and

construction. Where suppliers

can show a range of mask sizes

and extensive testing under

various motion conditions a low

leakage level can be assessed.

In the case of the upcoming ASTM

standards the leakage

declaration is left to the

manufacturer with little

assurance that low leakage will

be achieved in any specific

situation.

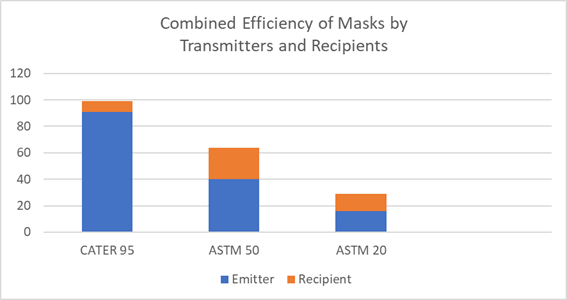

Masks are worn by the both the

transmitter and the recipient.

So the total virus inhaled

becomes a function of the

removal in the two sets of

masks.

|

Virus Penetration as a Percent of Total Load |

||||

|

Mask Type |

Location |

CATER 95 |

ASTM 50 |

ASTM 20 |

|

Virus Leaks |

Emitter |

4 |

20 |

20 |

|

Virus Penetration |

Emitter

|

5 |

40 |

64 |

|

Total Virus Emission |

Emitter |

9 |

60 |

84 |

|

Virus Leaks |

Recipient |

0.36 |

12 |

17 |

|

Virus Penetration |

Recipient |

0.45 |

24 |

54 |

|

Total Virus Inhaled |

Recipient |

0.85 |

36 |

71 |

The CATER 95 mask is therefore

71 times more effective at

preventing virus inhalation than

is an ASTM 20 mask. Granted that

fitness and other variables are

not precisely quantified but

this is a reasonable comparison.

Another approach is to compare

combined efficiency.

If

the decision is made on a basis

of comparative efficiency it is

easy to argue that a less

efficient mask is better than

nothing. At least an ASTM 20

will remove 29% of the virus if

worn by all.

But when you consider

that it allows 71 times as much

virus to penetrate as does a

CATER 95 mask this is a powerful

metric and one that can be used

in a total plan which includes

social distancing, HVAC, and

lockdowns.

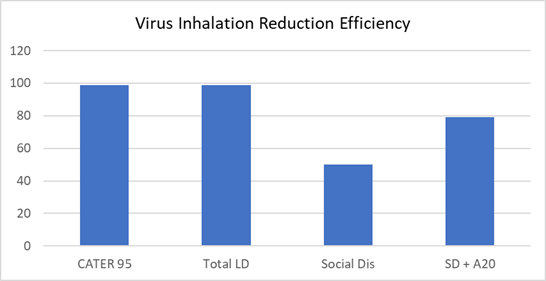

The selection of more efficient

masks can be viewed from the

perspective of resumption of

more normal behavior.

Rigorous Social distancing

including prevention of large

gatherings could have an effect

of reducing virus inhalation by

40%.

If partial lockdown is

combined with ASTM 20 masks a

total reduction of 79% might be

achieved. It could be argued

that if everyone wore CATER 95

mask you could eliminate most

social distancing. In the case

of bars fan filter units and

directional air flow would be

needed because of the need to

remove masks while drinking or

eating.

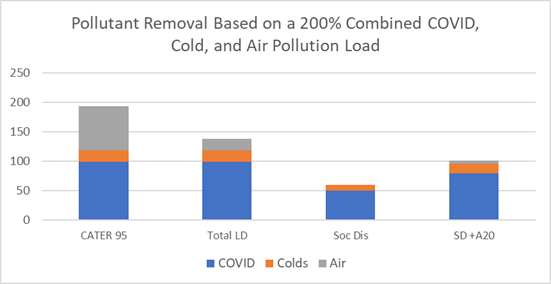

The

value of CATER 95 masks is even

greater compared to alternatives

when you consider that air

pollution, wildfires and other

air contaminants are equally

important. Hypothetically let’s

assume a total load which is

200% of the COVID. So the COVID

load could equal 50% of the

contamination (100), colds and

other virus related infections

are 10% (20) and air pollutants

and other air contaminants are

40% (80).

The graph then reflects a

total contaminant load of 200

It is clear that the benefit of

CATER 95 masks is far superior

to the alternatives when all

pollutants are considered.

Social distancing does not

reduce the amount of air

pollutants inhaled.

Mask efficiency should be the

basis of all the social

distancing, lockdowns, school,

bar and

restaurant openings. If

everyone wears a highly

efficient mask there will be the

ability to return to near normal

activities while reducing the

COVID spread.

Ignoring mask efficiency is as

illogical as saying social

distancing of one foot or one

mile should be treated equally.

The mask protection has been

proven in every pandemic.

Doctors were kept safe from

EBOLA by wearing masks and

taking other protections. The

highly efficient masks

provided the 99 % protection but

other PPE assured that the

protection was 99.9999%.

It is recommended that we

immediately change our strategy

and consider mask effectiveness

as the foundation of any

program.

Cummins is Making Masks with

Uniquely Charged Meltblowns

Cummins is making material for

millions of face masks out of

its Cookeville, TN, filtration

plant — thanks to a partnership

with the U.S. Department of

Energy’s Oak Ridge National

Laboratory nearby.

“Because of our expertise in the

automotive filtration industry,

we believed we could adapt to

supply the filter media used in

the face masks worn by

healthcare providers, which are

also in high demand across the

nation,” Christopher Holm,

director of filter media

technology and IP at Cummins,

said in a news release posted

yesterday.

Oak Ridge’s Carbon Fiber

Technology Facility meanwhile

worked with Peter Tsai, the

inventor of N95 filter media, to

develop a novel in-line charging

device that could be placed on

the precursor production line to

electrostatically charge

melt-blown material made of

polypropylene or PP.

Electrostatically charging the

material with millions of

microfibers layered on top of

each other creates a filter

material able to remove more

than 95% of submicron particles

and viruses such as the one that

causes COVID-19.

“We reached our target goal in

only a few weeks on pilot scale

melt blowing capability at the

CFTF and had the capability to

produce filter media for 9,000

masks per hour when we connected

with Cummins for potential

technology transfer and scale

up,” said Merlin Theodore,

director of the CFTF at Oak

Ridge. “Cummins was an ideal

partner to scale what we had

accomplished and helped us

produce material that passed all

required testing for filter

media.”

ORNL’s research team designed

and manufactured a custom

electrostatic charging device

for Cummins, assisting in the

installation of the device on

the company’s Cookeville

facility production line.

“Their research has made it

possible to be where we are

today,” Holm said. “We can

manufacture material that has

passed all the required testing

for N95 filter media.”

Two months ago, Cummins had

never produced filter media for

face masks. Today, it’s already

shipped material to multiple

customers across the country for

the production of millions of

masks.

BelEmsa Producing 200 Million

Masks per Month

BelEmsa, one of the leading

manufacturers of disposable

hygienic products, has increased

mask production to 200 million

pieces per month in Europe,

according to Aleksandr Kolesnov,

the first deputy director of

BelEmsa in an article in

Nonwovens Industry.

In the fight against the novel

coronavirus, medical masks are a

vital item for healthcare

workers on the frontline.

Kolesnov states, “We are fully

aware that access to PPE is

challenging and we must secure

the production of such an

important item to encourage

business organizations and

public health through the

recovery period.”

Detailed research on face masks

have been conducted by the

BelEmsa R&D project team since

the beginning of the Covid-19

outbreak, Kolesnov adds. “We

were aware that performance and

comfort requirements must be

offered under hygienic

conditions due to public needs.

We applied extensive know-how

accumulated through our

experience and created soft ear

loop masks for perfect fit and

comfortable use. Meanwhile,

BelEmsa worked closely with EC

accredited laboratories and

German Federal Institute for

Drugs and Medical Devices (BfArM)

for manufacturing facilities at

European standards.

"We risk significant amount of

funds and invested millions in

machinery, raw materials,

hundreds of new employees and

factory space to manufacture an

item projected to have a

short-lived demand. However,

contributing to society has

become one of our key priorities

under the current

circumstances,” he continues.

According to Kolesnov, BelEmsa

has never experienced challenges

in nonwoven materials, logistics

and other key equipment thanks

to its long standing experience

and reputation in the hygiene

industry. He adds, “We have

always been a reliable partner

to the governments and

healthcare institutions to

ensure high-quality medical

products."

Kolesnov ends, “I’m proud of the

fantastic efforts of our

operational team who took our

business out of China and

brought to home. BelEmsa become

the first company producing what

it says is a unique comfortable

ear loop mask in Europe and

offering this innovative item

with the Senso Med brand since

June.”

H+V will Expand to 100 Million

Mask Equivalents per Year

The Department of Defense (DOD),

in coordination with the

Department of Health and Human

Services (HHS), has awarded a

$2.5 million contract to

nonwovens manufacturer

Hollingsworth & Vose, to

increase domestic production

capability of filter media.

This industrial base expansion

effort will allow Hollingsworth

& Vose to increase production

capacity to 100 million mask

equivalents per year in Floyd,

VA by October 2021, to support

the production of filter media.

The DOD’s Defense Assisted

Acquisition Cell led this effort

in coordination with the

Department of the Air Force’s

Acquisition COVID-19 Task Force.

This effort, funded through the

HHS Coronavirus Aid, Relief and

Economic Security (CARES) Act,

supports domestic industrial

base expansion for critical

medical resources.