CATER Mask

Decisions

December 10, 2020

Clarification on CDC ASTM

Relationship

Construction Industry is a Long

Term CATER Mask Purchaser

A Guide to Respirators Used for

Dust in Construction Created by

NIOSH

Purar Mask Inward Leakage is

Less Than 2%

China Revised Respirator

Standard on July 1, 2020

SGS Provides Mask Testing

Services

SGS Provides Summary of French

Stipulations for Clear Masks

___________________________________________________________________________

Clarification on CDC ASTM

Relationship

Our article yesterday indicated

that ASTM and CDC are working

together on the mask standard.

This is not a partnership.

It so happens that the

Chair of the ASTM committee

drafting the barrier mask

standard is a senior leader in

NIOSH, a unit of CDC. But

CDC is not allowed

to acknowledge or embrace

the developing standard.

They are aware and have

encouraged their NIOSH

representative to devote full

attention to the standard, but

they have not acknowledged or

recommended the standard.

Construction Industry is a Long

Term CATER Mask Purchaser

After a huge increase in CATER

mask purchases to mitigate COVID

there are many markets where

CATER masks can gain market

share. One of them is

construction. Due to COVID there

is a big demand for CATER masks

in construction. Suppliers have

to explain to the industry why

CATER masks will be the future

choice for low level dust

environments and maybe even for

high dust level environments.

For example supplier personnel

visit construction sites for

periods as short as one hour and

have to wear masks during their

stay. They can have CATER masks

with corporate logos.

The construction industry is

accustomed to masks for COVID.

It is now the time for the

industry to consider CATER masks

for a range of activities. The

difference between COVID and

many construction applications

is that the particulate load is

very high. This makes it logical

to use disposable masks.

However, in most uses the dust

load is moderate. A washable

CATER mask with filter inserts

may be the best. While face

coverings are recommended and

even required on construction

sites across the country,

construction pros have a range

of reasons for not liking them.

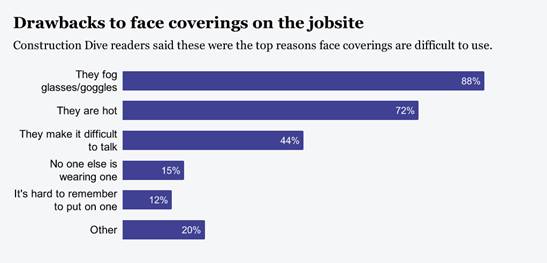

According to Construction

Drive they are seen as a

necessary evil, with 67% of

respondents to Construction

Dive's June 12 Friday

Feedback survey saying that they

are an important means of

protection from COVID-19. About

two-thirds of respondents also

said they are required on their

jobsites, either by their firms

or by government protocols.

While construction pros said

they see the need for face

coverings on jobsites, they

don’t always like having to wear

one. Drawbacks include the fact

that they can make the wearer

feel hot and tend to fog

eyeglasses and safety goggles.

Other reasons mentioned were

that they make it hard to

breathe during strenuous

activities, they can fall apart,

and they irritate the skin

behind the ears.

Most construction workers and

site managers are very familiar

with the personal protective

equipment (PPE) that helps

prevent workplace injuries to

the head, eyes, respiratory

system and other vulnerable

areas of the body.

OSHA, the U.S. agency that

mandates the use of PPE on

construction projects and in

other work environments across a

multitude of industries, also

requires employers to train

workers on how to use the

equipment appropriately. The

agency can dish out major fines

if employers don't take this

important step.

So, those in the construction

industry are used to seeing

packaging with instructions

about how to use respirators and

other face coverings, even as

this type of PPE has come into

play in the general population

as people try or protect

themselves from the novel

coronavirus.

The instructions available for 3M's

N95 respirator,

for example, offer a brief,

step-by-step tutorial, complete

with photos, on how to don the

equipment and make sure it's

sealed against the wearer's

skin. The material also comes

with information about which

OSHA standard the respirator

meets and against which

contaminants it protects. The

packaging itself also comes with

instructions.

Not so for other types of fabric

face coverings that contractors

have been buying and wearing as

protection against the

coronavirus. Generally, it's

been a free-for-all as far as

the types of masks available,

whether professionally

manufactured or homemade. The

accompanying advice on how to

wear them and how well they

protect the wearer varies as

well.

But that could be about to

change.

The PPE industry, led by safety

standard organization ASTM

International, is working on a

standard that would specify design

and performance criteria for

reusable masks.

The group, established in July,

aims to set requirements for:

-

The general

construction of

masks.

-

How the mask is

secured to and

stays affixed to

the user's head.

-

How well masks

filter out

bacterial and

solid

particulates.

-

Inhalation and

exhalation

breathing

resistances.

-

Size and fit

testing.

-

Affixing and

removing masks,

sizing, cleaning

and recommended

period of use.

The group is also working to

establish how much of this

information would be displayed

on mask packaging. The standard

would not supplant current mask

requirements for healthcare

workers nor OSHA industry

standards.

A Guide to Respirators Used for

Dust in Construction Created by

NIOSH

This guide cites the advantages

of light filtering facepiece

respirators (FFRs). CATER masks

have many advantages over

disposables. The paragraphs in

red below are particularly

applicable.

Construction dust can cause

serious damage to workers’

health and life-threatening

diseases. Construction workers

can be exposed to many types of

dust, such as silica, wood, and

lead dust. Workplace exposure to

small particles of silica dust,

also known as respirable

crystalline silica, can lead to

serious diseases, including

silicosis, a progressive lung

disease marked by scarring and

thickening of the lung tissue;

lung cancer; chronic obstructive

pulmonary disease (COPD); and

kidney disease. It’s estimated

that about 2 million

construction workers are exposed

to silica dust on the job [CDC

2020].

NIOSH sets Recommended Exposure

Limits (RELs), including a suggested

limit of

exposure to silica dust. A

recent study of workers exposed

to silica dust by industry

published in the American

Journal of Industrial Medicine found

that of 100,000 workers who were

exposed above the NIOSH REL, 8

out of 10 of those workers were

in the construction industry [Doney

et al. 2020].

Construction workers can be

exposed to silica dust from many

sources. For example, concrete

workers can be exposed to silica

dust during mixing, sawing,

jackhammering, chipping,

grinding, and cleaning

operations. Masons can be

exposed when cutting concrete

blocks and bricks, mixing

mortar, and tuckpointing. Tile

workers can be exposed when

cutting ceramic tiles or stone.

Highway, street, and bridge

construction workers can be

exposed during abrasive

blasting, drilling, milling,

breaking, and cutting concrete.

Site preparation workers can be

exposed during earthmoving,

excavation and trenching, and

demolition, and drywall workers

can be exposed when cutting

drywall and sanding joints.

The Occupational Safety and

Health Administration (OSHA)

silica dust standard for

construction requires employers

to limit worker exposures to

silica dust and protect them [29

CFR 1926.1153]. Table

1 in

29 CFR 1926.1153 has simplified

the compliance process in

construction by matching 18

common construction tasks with

effective dust control methods

and respiratory protection.

Employers who use the controls

specified in Table 1 are in

compliance when they perform

those tasks. If controls are not

being used, or when performing

tasks not listed in Table 1,

employers are required to

conduct air sampling to measure

workers’ exposure to silica or

obtain objective data to

demonstrate that they comply.

In many cases, engineering

controls are not adequate for

safely controlling dust, and

respirators must be used. A

respirator is designed to

protect workers from inhaling

hazardous dusts when properly

used. OSHA regulations govern

the use of respirators in

construction [29

CFR 1926.103].

If respirators are used, a

respiratory protection program

is required to ensure that they

are used properly. OSHA

mandates specific requirements

for the use of respirators [29

CFR 1910.134(c)].

If the workplace is in compliance

with dust standards,

employers can permit workers to

wear air-purifying respirators,

following OSHA’s (Mandatory)

Information for Employees Using

Respirators When not Required

Under Standard [1910.134

App D ].

Under this Appendix, the

employer must meet the following

OSHA requirements:

-

Ensure proper

respirator use

and maintenance

per

manufacturer’s

instructions.

-

Ensure that only

NIOSH-certified

respirators are

used and ones

with the proper

design for the

application.

-

Ensure that the

exposure does

not involve

contaminants

that the

respirator is

not designed to

protect from.

i.e., gases,

vapors, or very

small particles

that the

respirator will

not collect.

-

Keep track of

the respirator

to avoid using

someone else’s.

Selecting the right

air-purifying respirator

requires an assessment of

workplace operations, processes

or environments that may create

a respiratory hazard [NIOSH

2019].

Selecting a Respirator for Dust

Control

The need for light comfortable

NIOSH-approved air-purifying

masks are available in two broad

classes: non-powered and

powered. Non-powered are

sometimes referred to as

negative-pressure respirators,

and powered respirators are

referred to as PAPRs (powered

air-purifying respirators).

Non-powered air-purifying

respirators

Several filter materials are

available for negative-pressure

respirators. Since some filters

are degraded by oil mist,

replaceable filter cartridges

are designated according to

their level of oil resistance,

as follows:

-

N-Series filters

are not

resistant to

oil.

-

R-Series filters

are

oil-Resistant up

to one shift.

-

P-Series filters

are oil-Proof.

For mineral dusts, such as

silica, any of these filters

will work unless the workplaces

has an oil mist source. The most

common oil mist sources in

construction comes from

percussion drills. These

workplaces should use type R or

P filters. If oil mist is

present, N-series filters will

not be effective and should not

be used. R-series filters should

be used for one shift, and

P-series filters should be

changed in accordance with the

manufacturer’s recommendations

[NIOSH 1996].

The dust (or mist) collection

efficiency of filter materials

also varies. Filter cartridges

are available in three

efficiency levels: 95%, 99%, and

99.97%, designated as 95, 99,

and 100. For example, an N95

filter is 95% efficient; an N99

filter is 99% efficient; and an

N100 filter is 99.97% efficient.

The most commonly purchased

filter types are N95s and P100s.

Type 95 filters usually have a

lower cost and breathing

resistance than type 100

filters. As the letter rating

and number rating increase,

breathing fatigue will also

increase.

Reusable half-masks and

face-filtering respirators are

non-powered negative-pressure

respirators.

Reusable Half-Masks

A reusable half-mask,

negative-pressure respirator,

consists of a filter-holding

unit called the facepiece or

mask, fabricated from molded

plastic or rubber. The mask

contains intake and exhaust

valves and is attached to straps

that ensure a tight fit to the

wearer’s face.

This type of half-mask

respirator has a

replaceable-filter that removes

dust when the facepiece seal is

leak-tight. The seal can

occasionally cause skin

irritation. These respirators

also interfere with conversation

and may interfere with

eyeglasses or goggles.

Filtering Facepiece Respirators

(FFRs)

FFRs, commonly called dust masks

are another type of negative

pressure air purifying

respirator. FFRs have a lighter

design than half-mask

respirators. The entire mask

is fabricated from filter

material that covers the mouth

and nose.

FFRs offer some advantages

compared to the

replaceable-filter respirators.

In particular, they are more

comfortable and require no

maintenance. It may be harder to

pass a fit test with an FFR than

a reusable half-mask. As a

result, they are often much less

effective than half-masks.

FFRs are certified by NIOSH

under the 42

CFR 84 respirator

certification tests.

Certification is no guarantee

that the mask will perform well

as worn. In one study of FFRs

[CDC 1998], the average dust

reduction was only 67%.

Powered Air-Purifying

Respirators (PAPRs)

Powered air-purifying

respirators (PAPRs) use a fan to

draw air through the filter to

the user. They are easier to

breathe through than negative

pressure air purifying

respirators; however, they need

a fully charged battery to work

properly. PAPRs have three

filter classes HE, PAPR100-N,

and PAPR100-P. All three filter

series must demonstrate a

minimum efficiency level of

99.97 percent. It is important

to know what the hazard is, and

how much of it is in the air, to

select the proper

filters/cartridges.

PAPRs are often designed with a

hard hat equipped with a

battery-powered fan or a

belt-worn battery and fan,

filtering system, and face

visor, thus providing protection

for the head, lungs, and eyes

and face within one unit.

Another advantage is a lack of

breathing resistance.

Loose-fitting PAPRs have the

ability to accommodate facial

hair. Tight-fitting facepiece

PAPRs are required by OSHA to be

fit-tested and worn without

facial hair.

The NIOSH Certified

Equipment List (CEL)

is a useful resource for making

a respirator selection. The

online CEL tool allows you to

define search criteria based on

characteristics of approved

respirators.

Guidelines for Respirator Use

Respirator wearers should follow

the manufacturer’s instructions.

Comfort is as important as a

tight seal. A worker may need to

try different size respirators

or respirators from different

manufacturers before finding the

best fit for his or her facial

structure. Once a respirator is

put on, positive

and negative pressure seal

checks are

necessary to ensure there are no

leaks that would degrade the

respirator’s effectiveness.

Respirator Maintenance

Basic respirator maintenance is

simple. The wearer should check

to ensure that the filter

cartridges are undamaged, the

inhalation and exhalation valves

are in working order, no straps

are slipping or broken, there

are no tears or deformities in

the facepiece, and the

respirator is reasonably clean.

Regular replacement of filters

is an important part of

respirator use. Normally,

filters should be replaced when

breathing resistance increases

and when they are damaged or

soiled or at the end of the

shift if exposed to oil mists.

Another approach is to replace

filters when the filter loading

reaches 200 mg of dust [NIOSH

2018]. NIOSH has additional

guidance on the reuse and

extended use of filters: Filtering

out Confusion: Frequently Asked

Questions about Respiratory

Protection, Respirator Reuse and

Extended Use.

Many construction tasks can

expose workers to hazardous

dust. Protect your workers by

selecting the appropriate

respirator for the job and

ensure it is used properly

according to the manufacturer’s

instructions and OSHA’s

mandates. Keep your workforce

safe and healthy.

CAPT Alan Echt, DrPH, CIH,

Senior Industrial Hygienist in

the NIOSH Office of Construction

Safety and Health (retired).

Christopher Coffey, Ph.D, is the

former Associate Director for

Science for the NIOSH National

Personal Protective Technology

Laboratory (retired).

Scott Earnest, PhD, PE, CSP, is

the Associate Director for

Construction Safety and Health.

Jeanette Novakovich, MA, MS,

PhD, is a Writer-Editor in the

NIOSH Division of Science

Integration.

CDR Elizabeth Garza, MPH,

CPH, is Assistant Coordinator

for the Construction Sector in

the NIOSH Office of Construction

Safety and Health.

Scott Breloff, Ph.D. is a

Biomedical Research Engineer in

the NOISH Office of Construction

Safety and Health.

Christina Socias-Morales, DrPH,

is a Research Epidemiologist in

the NIOSH Office of Construction

Safety and Health.

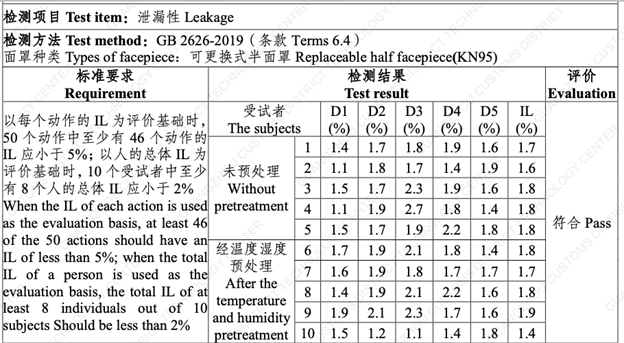

Purar Mask Inward Leakage is

Less Than 2%

The description of the M+H Purar

mask was provided in the Alert

yesterday. Here are results of

an inlet leakage fit test

conducted in accordance with the

Chinese Standard which is more

fully described in the next

article.

China Revised Respirator

Standard on July 1, 2020

China issued an updated version

of its mandatory national

standard GB 2626-2019

Respiratory protection -

Non-powered air-purifying

particle respirator. A summary

was provided by SGS (see next

article). The revised standard

became effective on July 1,

2020.

The Standardization

Administration of China issued

its mandatory national standard

GB 2626-2019 Respiratory

protection - Non-powered

air-purifying particle

respirator. The new mandatory

national standard will become

effective on July 1, 2020. Being

included in China’s No. 17

announcement on the newly

approved national standards in

2019, this new standard will

replace the previous version, GB

2626-2006.

Scope

This standard applies to

non-powered air-purifying

respirator which can help

provide respiratory protection

against particles. This standard

does not apply to respirator

which provide respiratory

protection against harmful gases

and vapor, and it is not

suitable for the respirators

used in hypoxic environments,

underwater operations, escape

and firefighting.

Technical Requirements

This mandatory national standard

specifies technical requirements

for Respiratory protection -

Non-powered air-purifying

particle respirator, and these

technical requirements include

general requirement, appearance

check, filter efficiency, inward

leakage performance, respiratory

resistance, exhalation valve,

dead space, visual field, head

harness, connection and

connecting parts, lens, air

tightness, flammability,

cleaning and disinfects,

practical performance,

information provided by

manufacturer, and package.

Compared with GB 2626-2006, GB

2626-2019 contains many

technical differences. The

detailed information can be

found in Appendix E in GB

2626-2019.

Classification and Marking

-

Classification

of facepiece

The facepiece shall be

classified according to its

structure, including disposable

facepiece, replaceable half face

piece and full-face piece.

-

Filter element

categorization

The filter element shall be

categorized according to the

filter efficiency, including

Category KN and Category KP.

Category KN is only used to

filter non-oily particles, and

Category KP is used to filter

oily particles and non-oily

particles.

-

Filter element

classification

The filter element shall be

classified according to the

levels of filter efficiency

given in Table 1.

|

CATEGORY OF FILTER ELEMENT |

CLASSIFICATION OF FILTER ELEMENT |

||

|

DISPOSABLE FACEPIECE |

REPLACEABLE HALF-FACE PIECE |

FULL-FACE PIECE |

|

|

Category KN |

KN90 |

KN90 |

KN95 |

|

Category KP |

KP90 |

KP90 |

KP95 |

SGS Provides Mask Testing

Services

SGS is one of the world’s

leading inspection,

verification, testing and

certification company.

It strives to be

recognized as the global

benchmark for quality and

integrity. With more than 89,000

employees, it operates a network

of more than 2,600 offices and

laboratories around the world.

Core services can be divided

into four categories:

-

Inspection: comprehensive

range of

world-leading

inspection and

verification

services, such

as checking the

condition and

weight of traded

goods at

transshipment,

help you to

control quantity

and quality, and

meet all

relevant

regulatory

requirements

across different

regions and

markets

-

Testing:

global network

of testing

facilities,

staffed by

knowledgeable

and experienced

personnel,

enable you to

reduce risks,

shorten time to

market and test

the quality,

safety and

performance of

your products

against relevant

health, safety

and regulatory

standards

-

Certification: we

enable you to

demonstrate that

your products,

processes,

systems or

services are

compliant with

either national

or international

standards and

regulations or

customer defined

standards,

through

certification

-

Verification: we

ensure that

products and

services comply

with global

standards and

local

regulations.

Combining global

coverage with

local knowledge,

unrivalled

experience and

expertise in

virtually every

industry, SGS

covers the

entire supply

chain from raw

materials to

final

consumption.

Established in 1878, SGS

transformed grain trading in

Europe by offering innovative

agricultural inspection

services. The Company was

registered in Geneva as Société

Générale de Surveillance in

1919. Shares were first listed

on (SWX) Swiss Exchange in 1981.

Since 2001, they have only one

class of shares consisting of

registered shares.

From its beginnings in 1878 as a

grain inspection house, it has

steadily grown into the role as

the industry leader. SGS have

done this through continual

improvement and innovation and

through supporting

customers’ operations by

reducing risk and improving

productivity.

SGS adds value from the design

room to the operating room. With

a full-range of services,

including product design

analysis, component and product

testing, auditing, inspection

and retail store checks, SGS

helps businesses deliver

well-designed, functional,

durable and safe products to

their customers. They have the

mask industry, regulatory and

technical expertise required to

check a products’ compliance

against relevant standards

and/or a manufacturer’s own

specifications.

SGS is committed to providing

information about development in

regulations for consumer

products as complimentary

services. Through a global

network of laboratories, SGS

provides a wide range of

services including

physical/mechanical testing,

analytical testing and

consultancy work for technical

and non-technical parameters

applicable to a comprehensive

range of consumer products.

Please do not hesitate to

contact us for further

information.

For more information contact:

Valerie CIMETIERE

Textile Expert

t: +33

(0)6 82 90 18 99

SGS

Provides Summary of French

Stipulations for Clear Masks

Since the early beginnings of

mask development as a new

accessory of daily life, an

issue has been raised as this

face covering hides our mouth

and lips from other people.

More than hiding facial

expression and smiles, hiding

the mouth raises the issue of

lip reading for the deaf or

hearing-impaired, isolating them

more than before.

The French authorities have

updated their requirements for

"Community masks" ("Grand

Public") including the option to

include a clear window but

maintaining breathability and

filtration performance when a

piece of transparent plastic

takes the place of textile

fabrics.

The French Cross Ministries Note

has been updated on 2020 July

22nd with specific requirements

for masks with clear window:

-

The impermeable

material must

not exceed 50%

of the mask

surface

-

The impermeable

material must

not exceed 50%

of an 8 cm

diameter circle.

The center of

the circle is

the midpoint

between the nose

and mouth of the

wearer

-

The permeable

material must

make up at least

50% of the mask

surface and must

have an air

permeability

greater than or

equal to 300

L/m2/s

-

The interface

between the

permeable

material and the

impermeable

material must

not leak

-

The impermeable

material should

not be pierced,

to avoid leaks

-

Filtration

efficiency at

3µm for the

permeable

material shall

be the same as

for "Grand

Public" masks

defined in

previous

versions of

Cross Ministries

Note (Annex I):

90% for Cat 1 and 70% for Cat. 2 according to DGA test method -

To avoid leakage

along the edges

of the mask, it

must allow a fit

on the face that

includes the

nose and chin

and the

adjustment at

the mouth must

not create a

retention zone

that can

accumulate

carbon dioxide

-

Washable window

masks must be

able to be

cleaned as other

kinds of

washable masks

except for

ironing (Annex

I)

Available in French only, the

Last version of the Cross

Ministries Note can be found here.