CATER Mask

Decisions

December 9, 2020

ASTM Base Efficiency Requirement can be Combined

With More Efficient Masks to Greatly Reduce

COVID Transmission

ASTM Working with CDC on a Minimum 20%

Efficiency Mask

Are Nanofiber Media Masks More Comfortable?

International Filtration News Insights

_____________________________________________________________________________

ASTM Base Efficiency Requirement can be Combined

With More Efficient Masks to Greatly Reduce

COVID Transmission

There are presently many masks being worn where

even with a perfect fit the efficiency will be

well less than 20%.

So an ASTM standard which would result in

all masks being somewhat effective will be a

contribution. With CATER Mask Decisions

we hope to guide a majority of purchasers to

purchase much more efficient masks.

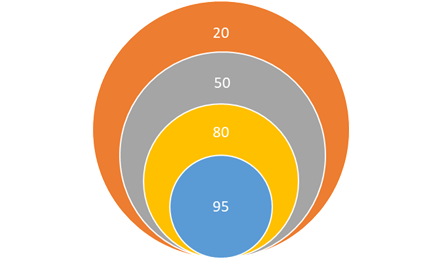

Mask Efficiency by Percentage of Wearers

At the very least we should be able to achieve a

distribution where 20% are wearing masks which

are 80% efficient or greater and 10% are wearing

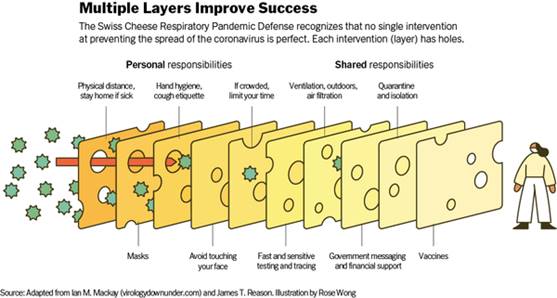

very efficient masks. The masks are part of the

swiss cheese defense program. The fewer holes in

the mask layer, the less need there is to

eliminate holes in the ventilation layer or in

quarantine.

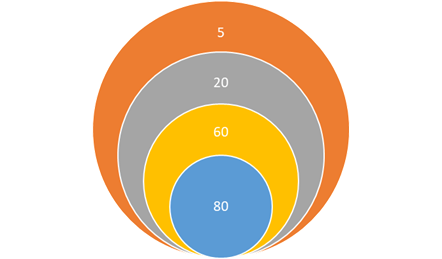

The ASTM working group struggled to find

compromise on inward leakage testing. There is

no consideration of quality control. So the

reality in terms of virus protection ranges

roughly from 5 to 80%.

Mask Effectiveness by Percentage of Wearers

It is therefore important that the ASTM standard

be supplemented by evaluation systems which

provide net effectiveness even if it is a range

such as shown in the following chart.

|

Effectiveness Rating % |

||

|

|

Minimum |

Maximum |

|

Level 1 |

0 |

10 |

|

Level 2 |

10 |

30 |

|

Level 3 |

50 |

70 |

|

Level 4 |

70 |

95 |

This effectiveness rating could be

net efficiency as calculated in the

following example.

|

Mask |

Efficiency % |

Unfiltered % |

Defects |

Net Efficiency % |

|

CATER 99 |

98-99 |

-2-8 |

0-1 |

89-97 |

|

CATER 95 |

92-97 |

-2-8 |

0-1 |

83-95 |

|

CATER 93 |

90-95 |

-2-8 |

0-1 |

82-93 |

|

Cloth |

50-60 |

-30-50 |

5-10 |

15-37 |

|

Surgical |

92-97 |

-25-40 |

0-1 |

40-72 |

ASTM Working with CDC on a Minimum 20%

Efficiency Mask

Obtaining agreement of mask standards is

difficult considering the revenues for

inefficient masks are many billions of dollars

per year. So the fact that ASTM has been working

with CDC and can probably have a consensus on a

minimum 20% efficiency mask is significant.

Also the clarification of methods to test

efficiency is also an important part of the

effort

This week the group received a

request to vote on

Ballot

Action: Working Draft #7, Standard Specification

for Barrier Face Coverings

This draft incorporates recommended changes from

the work group provided on Draft #6. A number of

specific changes have been made in response to

recent teleconferences to find potential areas

of consensus. Many of these comments are

substantial particularly as related to leakage

assessment, labeling, and conformity assessment.

Here are some

of the notes and clauses relative to

leakage assessment.

Note 4

– The leakage assessment represents the total

inward leakage likely to occur during wear.

Whether measured quantitatively or

assessed qualitatively, the leakage assessment

does not represent the likely outward leakage of

particles generated by the wearer. Thus, no

claims may be made with respect to the degree of

source control offering by the barrier face

covering based on the leakage assessment.

Note 5

– Leakage assessment, if measured quantitatively

on a barrier face covering that rests closely on

the face and thus has minimal inward volume, may

not be representative of true inward leakage.

4.1.3 Sub-micron particulate filtration

efficiency and air flow resistance do not

account for the leakage of air around the

perimeter of the barrier face covering. A

leakage assessment using a design analysis of

the product is required to assess the ability of

the barrier face covering design to minimize

inward leakage and provide appropriate coverage

for a range of wearer faces of different

dimensions. The design analysis can be conducted

by the manufacturer in a number of different

ways. The standard also permits supplemental the

use of quantitative information obtained from a

modified form of Test Method F3407 using test

subjects. This test yields a reportable ratio of

outside particulate concentration to the

concentration of particles in the wearer’s

breathing zone. Thus, a leakage ratio of 1.0

indicates the outside and inside environments

are equal and that particulate flow through gaps

in the barrier face covering (in addition to any

particulate that pass through the filtration

materials of the product

5.4 Leakage Assessment

5.4.1 The

leakage assessment shall be reported by

the manufacturer through a product design

analysis self-declaration.

5.4.2 The required self-declaration shall report

that the product minimizes leakage around the

edges or other areas of the product based upon

an analysis of the product design.

This statement can be included on any

self-declaration required as part of Guide

F3050, under Section 12 of this specification.

5.4.2.1 The manufacturer is permitted to conduct

quantitative testing

to supplement its product design analysis

self-declaration. When used, the leakage ratio

shall be evaluated using Test Method F3407, with

the modifications specified in 8.3.

5.4.3 Where barrier face coverings are reusable

and intended for laundering or cleaning, the

product design analysis shall be applied to

barrier face coverings both in a new condition

and after the maximum of laundering or cleaning

cycles as specified by the manufacturer

according to the manufacturer care instructions.

Note

13 – Examples of means to accomplish a leakage

assessment could include dimensional analysis,

computer modeling, placement of barrier face

coverings on standardized head or head-torso

forms and judging their respective areas of

coverage and conformity to the head or

head-torso form face showing conformance to the

fit and sizing characterizations of AATCC

M14-2020, or performing a quantitative analysis.[1]

A minimum particulate efficiency is cited

|

Performance

Property |

Criteria |

Test Method

Section |

|

Sub-micron

particulate

filtration

efficiency |

≥ 20% |

8.1 |

|

Air flow

resistance,

inhalation |

≤ 15 mm H2O |

8.2 |

Subsequently in the draft is an example showing

a better level 2 performance.

TABLE 2 Separate Classification of Face Covering

Performance PropertiesA

|

Performance

Property |

Level 1

(Acceptable) |

Level 2 (Better) |

|

Sub-micron

particulate

filtration

efficiency

(Effectiveness

of barrier face

covering for

capturing small

particles from

wearer; larger

percentages

indicate higher

performance) |

≥ 20% |

≥ 50% |

|

Air flow

resistance

(Indicative of

ease of

breathing while

wearing barrier

face covering;

lower

resistances

indicate more

breathable

products) |

≤ 15 mm H2O |

≤ 5 mm H2O |

This ASTM standard is a sign of progress.

It alerts buyers that all masks are not

equal. Suppliers of 95% efficient masks with

less than 8% inward leakage can use this

standard as a base and provide evidence as to

why their product achieves their claims,

Are Nanofiber Media Masks More Comfortable?

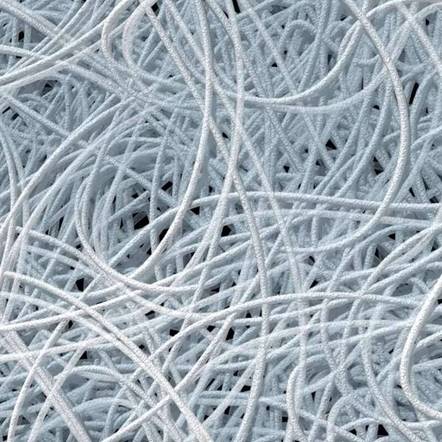

Revolution fibres make a

case that not only do nanofibers have

efficiency and breathability advantages they are

also more comfortable.

Nanofibers are incredibly small, synthetic

fibers – each measuring one thousand times

thinner than a human hair. Nanofibers form

complex strength through spiderweb-like

structures, which have an advantage over

conventional or even natural fibers due to their

extraordinarily large surface area and tiny pore

size. This combination creates maximum air flow

and particle capture – significantly more than

other synthetic or natural filters, achieving

greater efficiency down to PM0.3 microns.

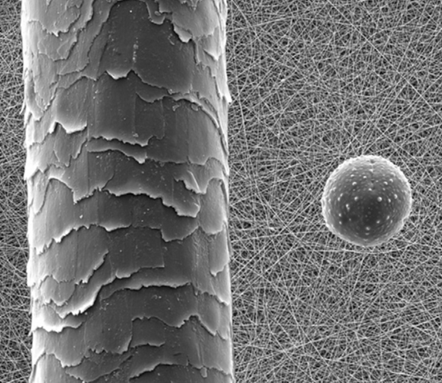

This image helps us visualize the size of a

nanofiber when compared to both hair and a speck

of pollen:

Its small size provides an array of benefits

when utilized in face mask technology –

including advanced protection and better

comfort.

Featuring a weaving design closely packed

together so microscopically that we are unable

to see them with the human eye, nanofibers craft

a small pore size and high surface-to-volume

ratio. This means the surface area and pores of

a face mask with nanofiber technology will not

allow cells to pass through to reach the wearer.

Simply, due to the unique and tough threading of

the nanofibers, everyday dangers such as

pollution, viruses, bacteria and more will be

unable to cross the threshold of the mask,

thereby enhancing protection from the outside

world. Not even water or liquid can penetrate

the surface, which is why it is such an

essential component of any truly effective face

mask.

Additionally, this works two ways, as a mask is

not only a protector of the individual wearing

the mask, but it also serves to halt the spread

of germs as well. When you’re sick, you should

have a mask on – especially if there are other

people in your household or if you are traveling

out to an appointment with a doctor. Nanofibers

block larger cells from escaping the mask, which

helps to ensure less spread of any unpleasant or

harmful ailment to unsuspecting passersby or

loved ones.

While many are aware of the advanced protection

that nanofibers provide in face mask technology,

what may come as a surprise is that this

material is also significantly more comfortable

than other fibers. The complexity of the

microscopic hair-like design makes the mask

lightweight and, therefore, extremely

breathable. It’s not simply a cloth over your

face – it’s a material that works with your body

to trap cells out but allow air to flow in, so

you don’t feel cramped or suffocated. This also

allows for better temperature regulation. More

airflow means less of a “humid” feeling, as if

the mask were a part of your face rather than

your face feeling as if it’s sweating into the

mask. The light, soft and airy material of

nanofibers ensures both short-term and long-term

wear is much more comfortable.

Overall, nanofibers have revolutionized the way

we keep people safe – with transformational

applications in healthcare advancements such as

tissue engineering, wound dressings, face masks

and more.

International Filtration News Insights

International Filtration News

has lots of good information relative to masks

We work closely with Matt Migliore who is the

editor. He just wrote an article on nanofibers

which is quite relevant. Here are some excerpts.

According to Dr. Vijayakumar, to truly deliver

on the benefits of increased efficiency and

decreased resistance in the filter, nanofibers

need to be in the ~100nm size range.

NXTNANO’s HYPR spinning production process is

capable of scaling to produce approximately 150

million square meters of Level 1 mask material

per year, according to McDowell. Described as a

derivative of electrospinning, the HYPR spinning

process allows NXTNANO to produce more and finer

fiber, more consistently, and with better

bonding than other nanofiber material options on

the market. It also permits flexibility to spin

multiple polymers simultaneously. “All of the

general issues you would see with

electrospinning we think we’ve pretty well

solved; for throughput, controllability, and

uptime,” said McDowell.

You can find the full article at

https://www.filtnews.com/nanofiber-filtration-challenges-and-opportunities/

There is an important article by Adrian Wilson

titled Facemask

materials, surface treatments, intelligent

sensors & carbon nanotubes.

Here is an excerpt.

NWI executive director Benham Pourdeyhimi

explained that the new media development arose

from reactivated work on microfibrillation,

which was initially undertaken for the

filtration industry.

N95 efficiency can be achieved with just two

layers of the new spunbond fabric. A combination

of one spunbond layer and a meltblown layer can

further achieve N99 efficiency.

The media also requires no electrostatic

charging, which has been another bottleneck in

the production of facemasks this year, and,

because the materials are strong – unlike

traditional meltblown materials – they can also

be cut and sewn by traditional techniques.

Further, they have the potential to be reused a

number of times after cleaning.

The full article is found at

https://www.filtnews.com/filtration-innovations-in-2020/