CATER Mask

Decisions

December 2, 2020

Expansion of CATER Mask Production is of Highest

Priority

Cleanrooms for Mask Production

New Mask Cleanroom in Wales

Mask Update from WHO

Netherlands Requires Masks in Indoor Public

Places

ANI Constructs Pilot Plant in Kansas

Elastic Cord Replacing Bands for Masks

_________________________________________________________________________

Expansion of CATER Mask Production is of Highest

Priority

A

combination of masks and vaccinations can create

herd immunity quickly. It will be a combination

of CATER, surgical and medium efficiency cloth

masks. It will not include inefficient cloth

masks.

Because CATER masks are tight fitting,

efficient, comfortable and attractive they will

be 93% effective where utilized. It was

determined that only one mask would be needed

per month and possibly only one per quarter due

to reusability. This will be the most

cost-effective option.

Therefore governments would be well served to

subsidize a massive CATER mask production

program. We have revised our timelines for

vaccinations and calculated the CATER mask need

|

Cater Masks Needed to Reach 70% Herd Immunity with 30 Day Life |

|||||||

|

Date |

Cumulative % Vaccinated |

Add % to Reach 70 |

Mask Inefficiency |

% Needing Masks 1.075 |

People Needing Masks millions |

Monthly Production Rate millions |

Monthly Revenues $ millions at $30/mask |

|

April 2021 |

20 |

50 |

7 |

54 |

3225 |

3225 |

96,750 |

|

June 2021 |

40 |

30 |

7 |

32 |

1920 |

1920 |

57,600 |

|

Sept 2021 |

50 |

20 |

7 |

22 |

1320 |

1320 |

39,600 |

|

Dec 2021 |

60 |

10 |

7 |

11 |

660 |

660 |

19,800 |

|

Feb 2022 |

65 |

5 |

7 |

5.4 |

323 |

323 |

9,690 |

In our previous alerts we used longer time lines

for immunization. We also showed the number of

disposable surgical masks which would be

necessary to achieve herd immunity. These

numbers are so large that there is no way enough

meltblowns could be produced in the next year to

meet the demands.

On the other hand CATER masks are reusable and

can incorporate nanofiber non wovens or membrane

media. So the only way masks can make a huge

impact on COVID in the short term is with

government subsidies for CATER mask suppliers.

If those subsidies are not forthcoming CATER

mask suppliers can still make a big contribution

by expanding as fast as possible but not beyond

the expected market in 2023 which is $0.8

billion to $2.5 billion just for the wealthiest

10%.

|

|

||||

|

|

COVID |

Other |

Total |

10% wealthiest |

|

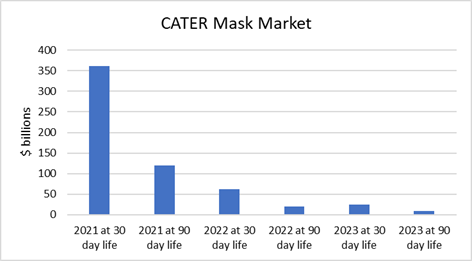

2021 at 30 day life |

360 |

1 |

361 |

36 |

|

2021 at 90 day life |

120 |

0.3 |

120.3 |

12 |

|

2022 at 30 day life |

60 |

2 |

62 |

6.2 |

|

2022 at 90 day life |

20 |

0.7 |

20.7 |

2.1 |

|

2023 at 30 day life |

21 |

4 |

25 |

2.5 |

|

2023 at 90 day life |

7 |

1.3 |

8.3 |

0.8 |

The present CATER mask revenues are less than

$100 million. In fact using a CATER 95 standard

the present revenues are below $60 million.

So there is the opportunity for suppliers

to grow rapidly.

Assuming the present revenues are $100 million

and the 10% wealthiest citizens will spend $800

million for CATER masks based on a 90 day life

in 2023, the present revenues are only 12.5% of

the 2023 revenues.

|

|

10% Wealthiest |

Present CATER Revenues |

Present Market % |

|

2021 at 30 day life |

36 |

0.1 |

0.2 |

|

2021 at 90 day life |

12.5 |

0.1 |

0.8 |

|

2022 at 30 day life |

6.2 |

0.1 |

1.6 |

|

2022 at 90 day life |

2.1 |

0.1 |

4.8 |

|

2023 at 30 day life |

2.5 |

0.1 |

4.0 |

|

2023 at 90 day life |

0.8 |

0.1 |

12.5 |

This would be an 800% growth rate over just

three years. With use of various media and

sub-contracting this is an achievement which can

be met.

This forecast can be the basis of CATER mask

strategy. There will be opportunities to

generate additional billions of dollars in sales

in the short term. But the risks involved are

too great for CATER mask suppliers to pursue

independently.

The Mcilvaine Company, Waterloo Filtration

Institute, and Vogmask have initiated a mask

rating service. This will show governments that

a big investment in CATER masks on a crash basis

can be justified. But CATER mask suppliers

cannot make

investments on this uncertain potential.

Cleanrooms for Mask Production

One of the

differences between masks used by the

public and masks used by medical care personnel

is the production cleanliness required. Masks

for the public can be produced in facilities

used for clothing of any type. Medical masks

have to be produced in cleanrooms which are five

times cleaner than ambient air. Ambient air is

Class 500,000 whereas the medical requirement is

ISO 8 or Class 100,000. Two ISO 8 cleanrooms for

mask production have just been completed in the

UK.

One supplier, Wiskind, says the modular

cleanroom is the answer because it can be built

quickly.

Compared with the traditional cleanroom, one of

the major advantages is the fast construction

speed and short construction period. The main

advantages of the modular cleanroom environment

are the speed and convenience of installation.

To achieve standardized production, 70% of the

construction tasks are completed in the factory,

improving the construction efficiency of

cleanroom material production by more than 15%,

shortening the construction period by 20% to

40%, and greatly improving the construction

quality,

A modular cleanroom requires FFU, floor, sensor,

pass box, escape door, air shower, hand washing

dryer, clean closet and other cleanroom

supporting facilities to choose from. These

devices are available from Wiskind. The

outsourcing cost and timeliness of enterprise

procurement.

The modular cleanroom system construction time

will be very short, which fully meets the urgent

construction needs of the mask workshop. Another

point worth paying attention to is whether the

mask workshop can quickly meet the cleanliness

requirements after being quickly built. Medical

masks, as a type II medical device, require that

the cleanliness of the production environment

air must meet the 100,000 level requirements.

New Mask Cleanroom in Wales

The urgency of pandemic builds means extremely

tight turnaround demands for design and build

providers. An example of this is the new 425 sqm

cleanroom in Wales that aimed to produce high

grade face coverings and masks for front line

workers The COVID-19 pandemic and the new

government advice/rules on mandatory face

coverings has seen a huge rise in demand for

face masks.

But how can the UK government satisfy such a

large and sustained increase in demand without

impacting on the supply of face masks for the

countries front-line National Health Service

(NHS) staff? The answer: build new state of the

art facilities in accelerated time frames. One

such facility is located at British Rototherm,

in Port Talbot, Wales. Cleanroom Solutions was

tasked with the design and build of the brand

new, 425 sqm cleanroom. The extreme urgency of

the build and difficulties getting construction

materials at short notice meant the build

programme had to be modified The facility was

designed in a matter of days, built in four

weeks, with production equipment installed at

the end of week four. This proved to be an

immense challenge and an even greater

achievement, testament to the national effort we

have seen throughout this pandemic.

The facility is an ISO Class 8 cleanroom to ISO

14644-1, which is required for production of

high grade face coverings and masks for front

line NHS workers. The cleanroom included

changing room and goods in/out airlock for

production materials. The facility was fully

air-conditioned for comfort conditions. Due to

the extreme urgency of the build and

difficulties getting construction materials at

short notice, the build programme had to be

modified. The walls were erected before the

steelwork and temporally supported until the

steelwork was delivered and constructed. The

walls were then connected to the steelwork, and

this was followed by the suspended ceiling. As

soon as a section of ceiling was in place, a

second team began working on fitting the fan

filter units (FFUs) and lights. Finally, the

vinyl floor was laid, enabling the client to

start to move their production equipment in.

Whilst the equipment was being installed the

ceilings were sealed and the room tested and

validated.

Cleanroom Solutions Site Director, Sean Gaylard,

said: “This has to be one of the most

challenging cleanroom installations that I can

recall us taking on and completing. In light of

the current world pandemic with many

manufacturers and suppliers still on furlough,

we managed to have the cleanroom ready for the

production equipment

within four weeks.

Mask Update from WHO

The World Health Organization (WHO) issued an update to coronavirus mask-wearing guidance for the first time in nearly six months. In the update, the health agency advises wearing a mask as part of “a comprehensive package of prevention and control measures” to limit the spread of COVID-19.

“A mask alone, even when used correctly, is insufficient to provide adequate protection or source control,” the Dec. 1 guidelines said. “Other infection prevention and control (IPC) measures include hand hygiene, physical distancing of at least 1 meter, avoidance of touching one’s face, respiratory etiquette, adequate ventilation in indoor settings, testing, contact tracing, quarantine and isolation.”

The agency further stated that depending on the

type of mask used, it can “be used either for

protection of health persons or to prevent

onward transmission (source control).” WHO

recommends that anyone with suspected or

confirmed coronavirus wear the mask while in the

presence of others and that proper use, storage,

cleaning and disposal are essential to

effectiveness.

In public, the agency advises using a risk-based

approach regarding the use of masks.

“In areas of known or suspected community or cluster SARS-CoV-2 transmission: WHO advises that the general public should wear a non-medical mask in indoor shared workplaces, schools, or outdoor settings where physical distancing of at least 1 meter cannot be maintained,” the guidelines stated. “If indoors, unless ventilation has been assessed to be adequate, WHO advises that the general public should wear a non-medical mask, regardless of whether physical distancing of at least 1 meter can be maintained.”

Regarding children, the agency advised against

mask use in those under 5 years of age. Many

states in the U.S. have recommended mask use in

children over age 2.

“Children aged up to 5 years should not wear

masks for source control,” WHO’s

guidelines state.

“For children between 6 and 11 years of age, a

risk-based approach should be applied to the

decision to use a mask; factors to be considered

in the risk-based approach include intensity of

SARS-CoV-2 transmission, child’s capacity to

comply with the appropriate use of masks and

availability of appropriate adult supervision,

local social and cultural environment, and

specific settings such as households with

elderly relatives, or schools.”

The agency noted that information regarding

transmission of coronavirus constantly evolving

based on new studies and data made available,

and as such, guidelines have to be revised and

updated.

Netherlands Requires Masks in Indoor Public

Places

The Netherlands has made it compulsory to wear a

face mask in indoor public spaces in an effort

to contain the spread of coronavirus.

The country is one of the last in Europe to

introduce such a measure. The rule will apply to

those over the age of 13 in public buildings

such as shops, railway stations and hairdressers

from Tuesday.

The Netherlands has been one of the country’s

worst affected by Europe's second wave of

Covid-19. It broke daily case records throughout

October, and the number of new confirmed

infections in the country of 17 million has

remained fairly stable at about 5,000 a day for

several weeks.

The new face mask rule will remain in place for

at least three months, with those who ignore it

facing a fine of up to €95 (£85; $113).

But there are questions over how the measure

will be enforced. Major retail chains have said

they will inform customers about the rule but

not refuse entry to those without a face

covering.

"This is not something which we consider part of

our job as shop workers," a spokesman for the

Mirage retail group said.

Separately, under the measure, students and teachers will have to wear a mask when moving around school buildings but not during lessons. Teachers who move around the classroom while talking, however, will have to put on a face covering.

Places of worship, such as churches, temples, and mosques, are exempt.

"Making face masks mandatory almost everywhere

makes it clearer what the rules are," a

government website reads. "[We] want to prevent

the spread of the coronavirus."

ANI Constructs Pilot Plant in Kansas

Applied Nanoscience Inc. (ANI), a

nanotechnology-based air filtration performance

company, announced that construction of a pilot

plant has begun in Downs, KS, with direct

participation of the Kansas Department of

Commerce. Last month, a wholly owned

L.L.C. of the company was awarded a PPE

Manufacturing Grant to aid in the global fight

against Covid-19. ANI had earlier this year

announced the completion of process enhancements

to ensure reliable production scale-up of the

company’s proprietary antimicrobial NanoFense

technology, a U.S. patented nanoparticle

formulation. The company is working closely with

both Downs Enterprises, Inc. and Kansas State

University’s Technology Development Institute

(TDI) on the project.

“This award from the Kansas Department of

Commerce acknowledges the global need for air

filtration companies to offer genuinely

protective and higher-performance products. This

better positions ANI as an attractive, strategic

partner with filter media producers as well as

established air filtration product companies who

can now fully exploit our technology in efforts

to better protect people from harmful pathogens.

Our technology, disruptive product design

efforts and issued patent protection are all

intended to provide more safety to consumers

while creating an effective competitive

advantage in many markets currently utilizing

generic,

untreated filter media,” states Thomas Allen,

president and CEO, ANI.

ANI has (16) issued international patents

protecting their broad NEFT platform in 13

countries spanning five continents. The patent

coverage includes three main methods of

associating nanoparticles with filter media: (1)

coating the filter media with a powder of

nanoparticles, (2) impregnating the

nanoparticles into the filter media, and (3)

having pellets of nanoparticles located adjacent

to the filter media.

Elastic Cord Replacing Bands for Masks

The current pandemic situation around the world

has created a critical gap in terms of surgical

mask availability. Suddenly many countries have

recognized an internal gap for the capacity of

manufacturing surgical masks and even at the

government level there have been actions to

encourage key enterprises to invest in

converters and install domestic capacity.

Nevertheless, another gap that has come up is

related to the availability of several raw

materials.

Many producers are aware of the criticality of

applying elastic cord at high speed, being the

most common design of masks sourced in Asia.

In addition, elastic cords are replacing the

elastic bands in new mask designs. Despite this

latter design was much more “process friendly,”

especially for high-speed converters, many

producers have decided for a more pragmatic

approach by simply reapplying the elastic

laminated material generally used for other

applications, such as diaper elastic back ears.

As a result, many consumers experienced an

uncomfortable feeling due to the fact that the

elastic characteristics were tailored for a

fastening system application. This problem has

become even more critical after several hours

wearing a mask and it is known as the “dumbo”

effect.

In order to eliminate the consumer’s

uncomfortable feeling, Texol’s R&D organization

has designed “Elamask,” a laminated material

intended to show high elongation with low force

retraction.

The material is available in a basis weight of

100 gsm and has already been tested on the main

mask high speed converter machine proving good

runnability and good bonding properties. Most of

its customers have already switched to Texol’s “Elamask.”